Extrusion moulding apparatus for large-scale macromolecular product and process thereof

An extrusion molding and polymer technology, applied in the field of extruder and its molding process, can solve the problems of fluctuating extrusion product accuracy, affecting product quality, and impact, and achieve the effect of reducing processing and adjustment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

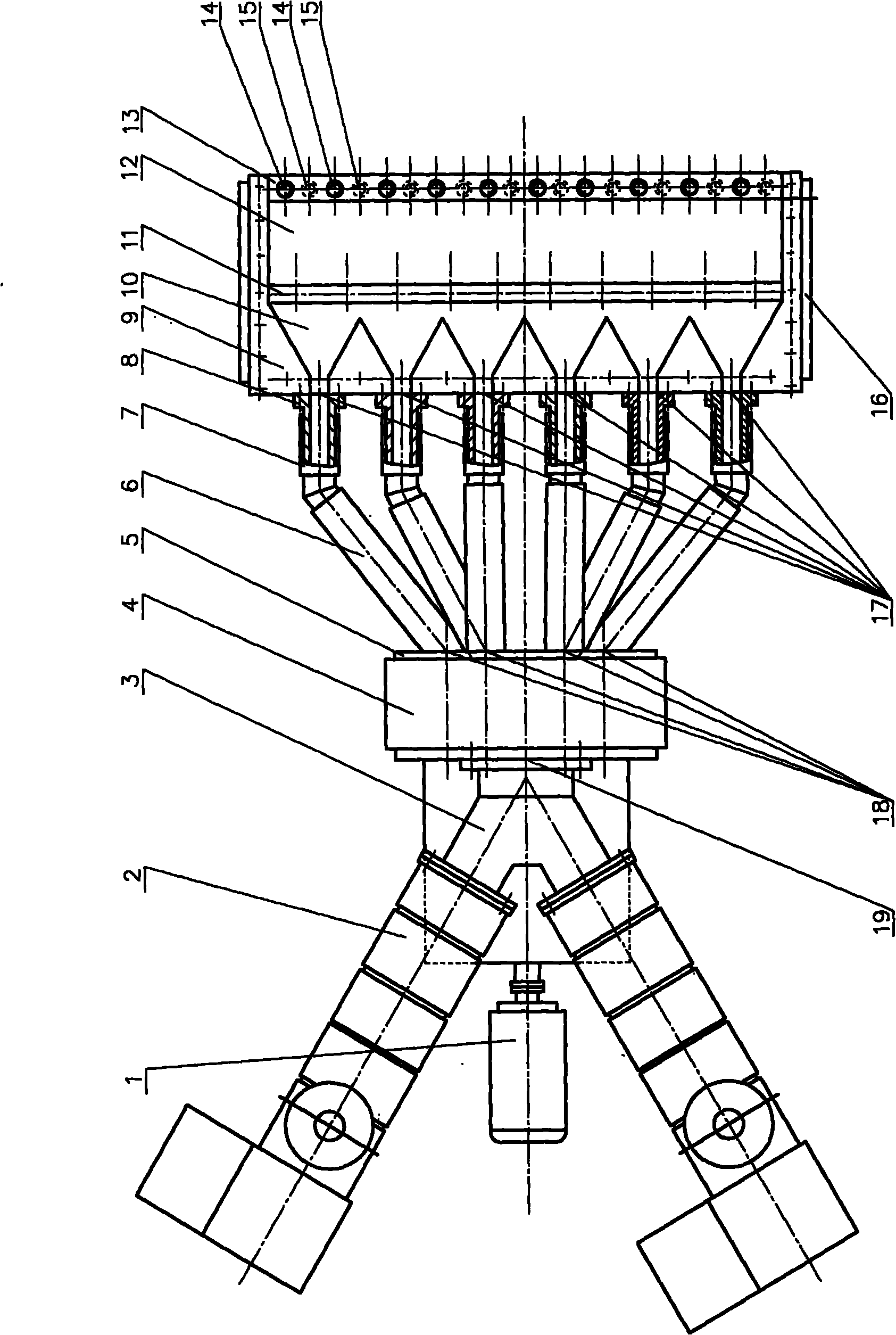

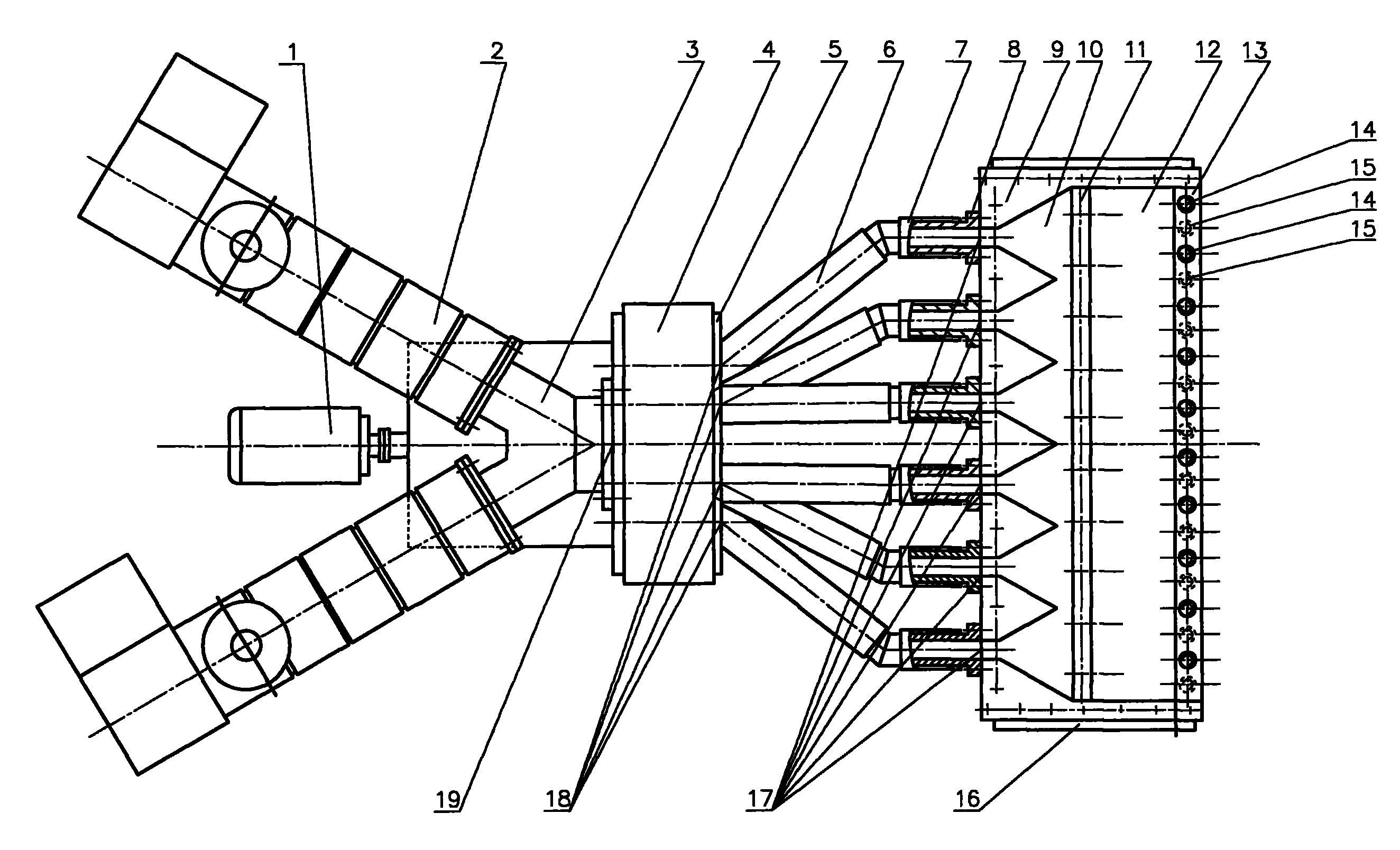

[0015] figure 1 Shown is one embodiment of the invention, the article being a sheet. The present invention is an extrusion molding device for large-scale polymer products, which mainly includes a melt planetary gear pump transmission and control device 1, an extrusion system 2, a melt collection device 3, a melt planetary gear pump temperature control device 4, and a melt planetary pump Gear pump 5, branch flow channel 6, branch flow channel temperature control device 7, branch flow channel connector 8, machine head body 9, branch flow channel 10 in the machine head, damping device 11, forming flow channel 12, die 13, Die adjustment device, head temperature control device 16, the die adjustment device includes a die installation screw 14, a die adjustment screw 15, the inlet of the melt collection device 3 is connected with the melt outlet of the extrusion system 2, and the melt is collected The device 3 brings together the melts from one or more extruders. The melt collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com