Flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure

A LED chip, flip-chip welding technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of limited thermal conductive metal bumps, chip PN short circuit, etc., to achieve better heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

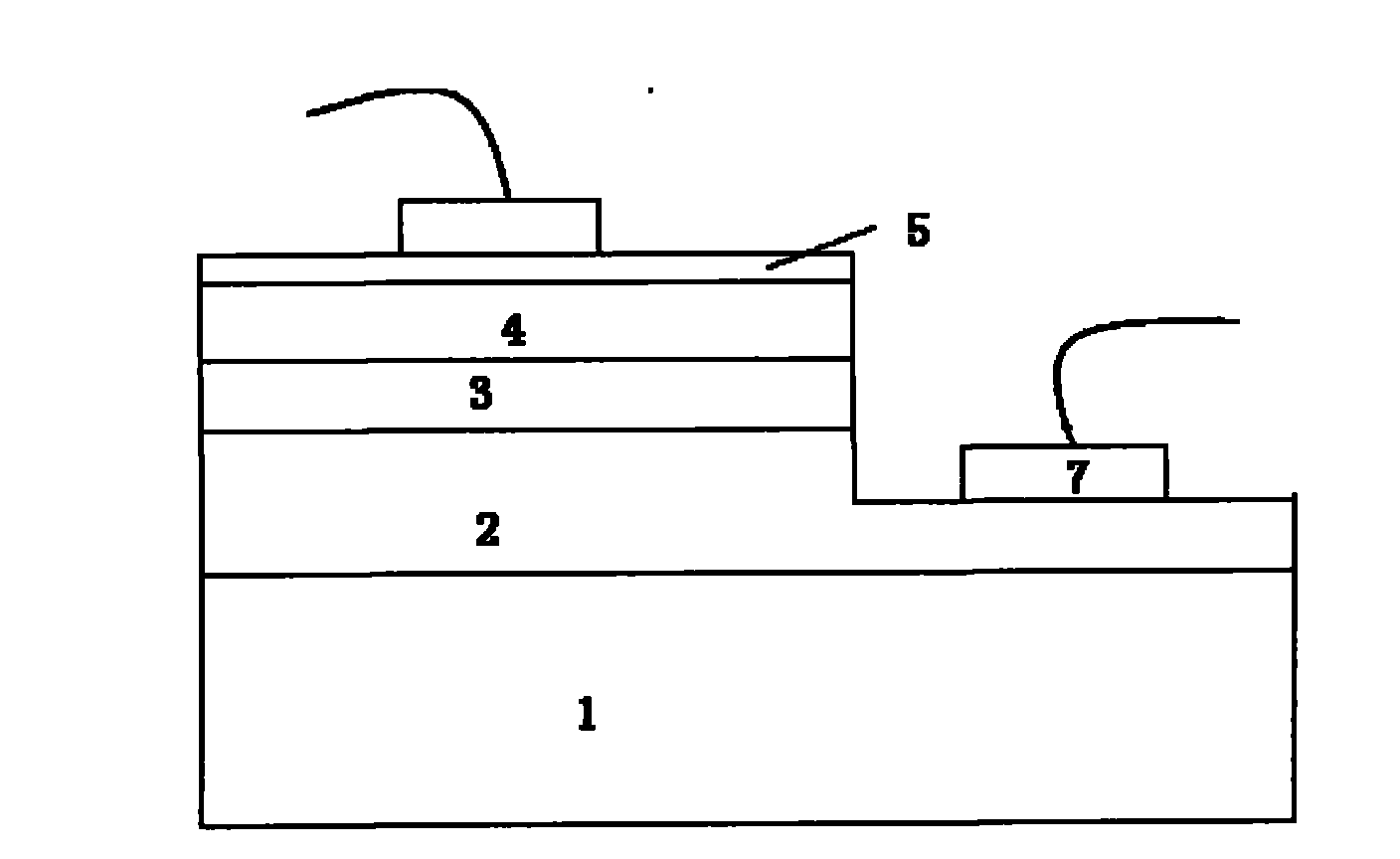

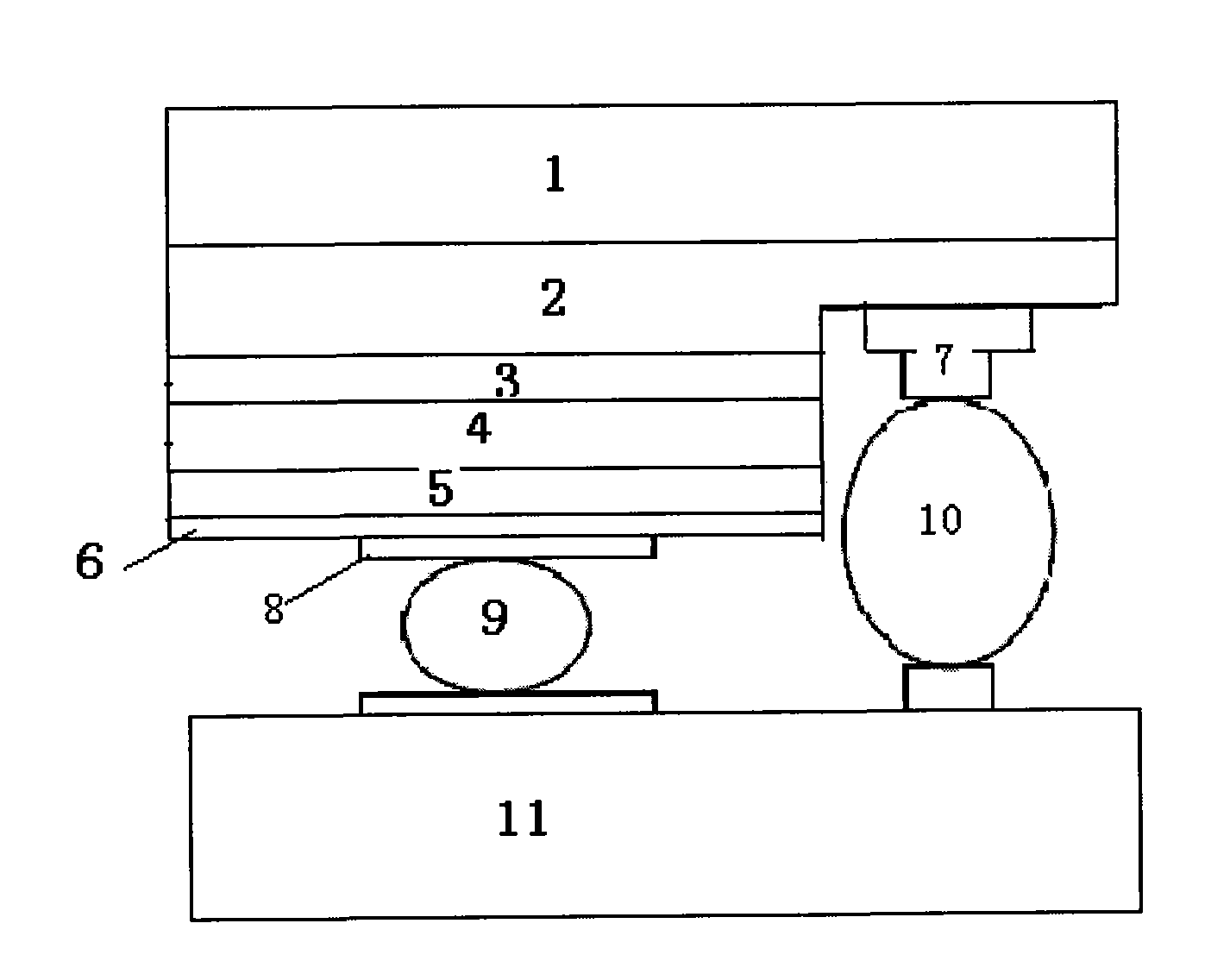

[0015] The structure of the flat panel flip-chip GaN-based LED of the present invention is in figure 2 Improvements are made based on the flip-chip structure shown, as image 3 and Figure 4 As shown, a step surface to the N-type GaN layer 4 is etched on the light reflection layer 6, an N electrode 7 is formed on the N-type GaN layer 4 of the step surface, and a P electrode 8 is formed on the light reflection layer 6, The outer ends of the N electrode 7 and the P electrode 8 are in the same horizontal plane. A layer of transparent insulating dielectric film 12 is plated on other areas except the P electrode pad and the N electrode pad on the surface where the P electrode pad and the N electrode pad are located. The outer end of the P electrode welding point is made with a P welding plate 9, and the outer end of the N electrode welding point is made with an N welding plate 10, and the P welding plate 9 and the N welding plate 10 are welded to the P electrode area and the N o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com