Oil and water combined heat exchanger

A heat exchanger and water radiator technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problems of large axial size, inconvenient installation and layout, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

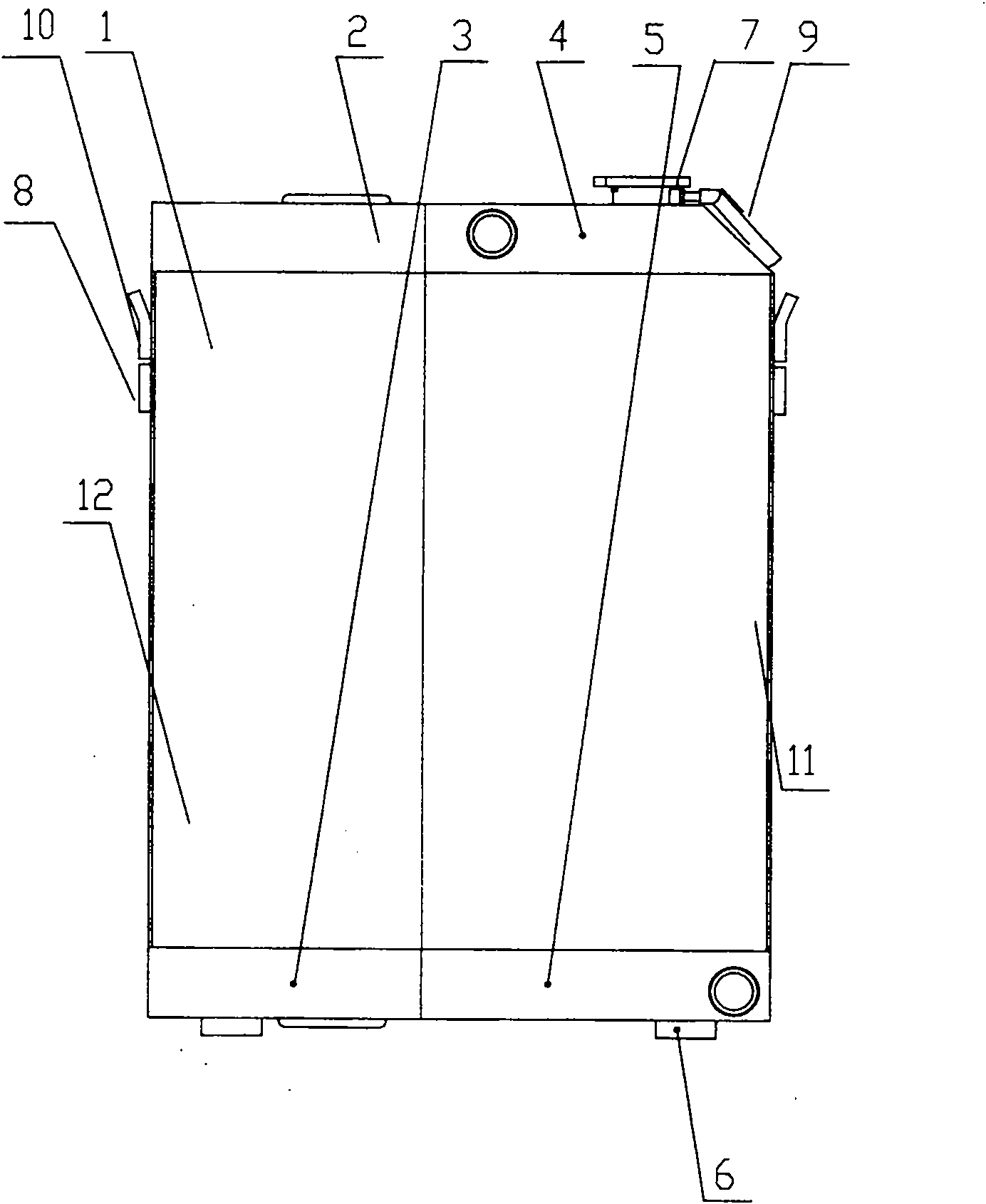

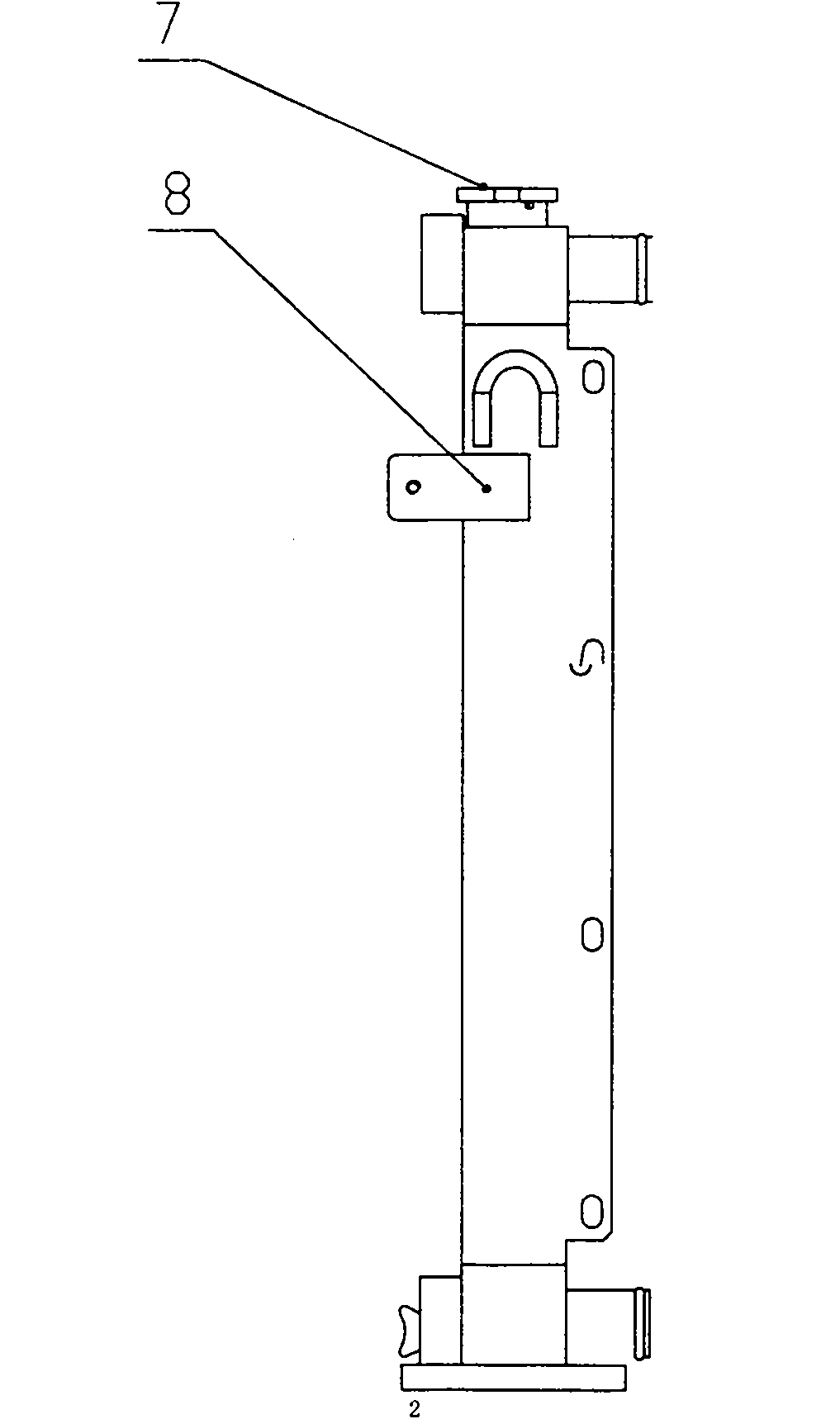

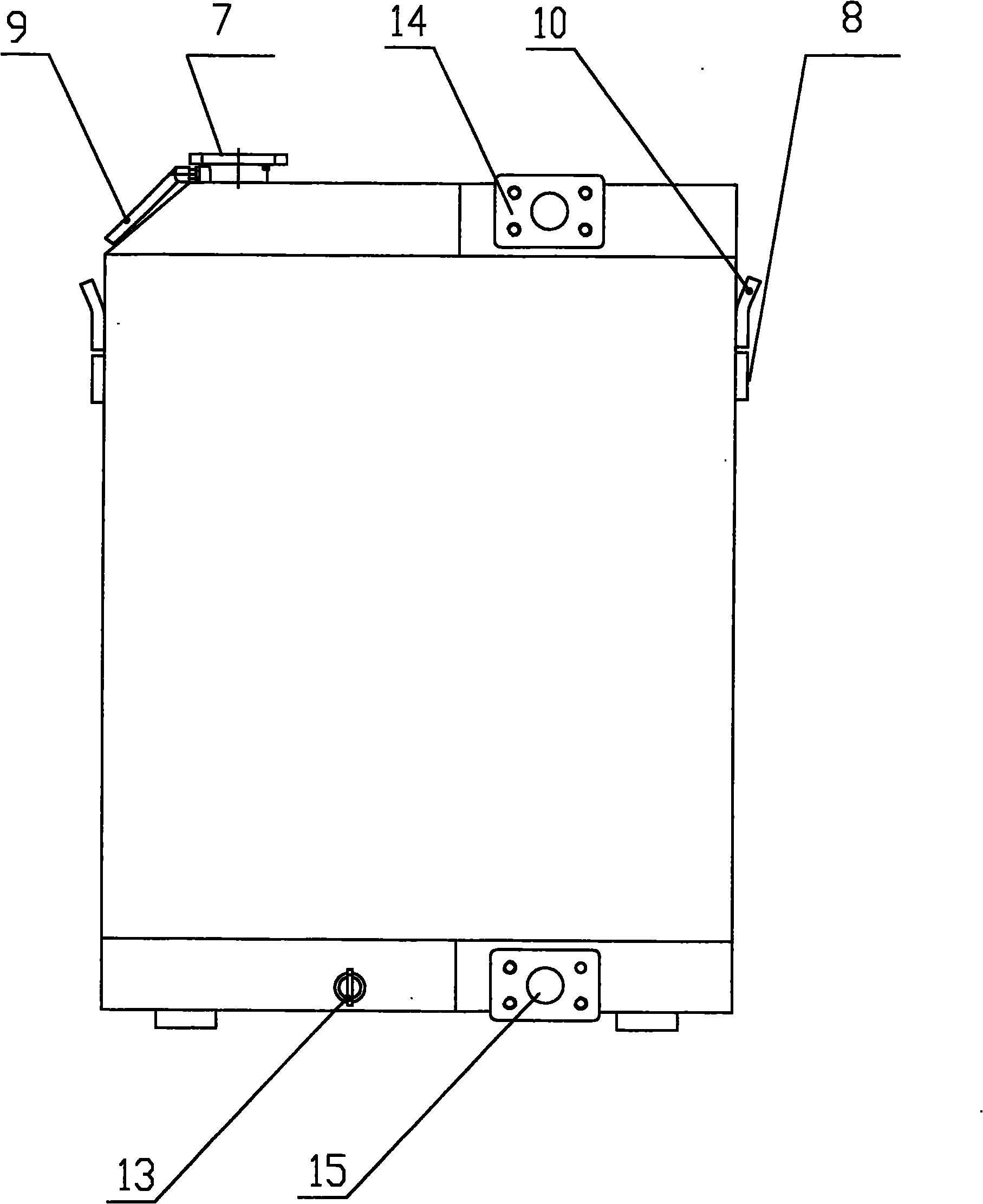

[0021] according to figure 1 , figure 2 , image 3 As shown, the core body 11 of the aluminum plate-fin type water radiator and the core body 12 of the aluminum plate-fin type hydraulic oil cooler are brazed into an integral core body 1, and the head 2 and the head 3 are welded by argon arc welded separately figure 1 The upper and lower ends of the core body 12 of the aluminum plate-fin hydraulic oil cooler shown are qualified for the pressure test; the head 4 and the head 5 are respectively welded on the figure 1 The upper and lower ends of the aluminum plate-fin water radiator core body 11 shown are qualified for the pressure test; finally, the mounting block 8 and the lifting lug 10 are welded to the figure 1 The left and right sides of the core body 1 shown are one on each side, and the lifting lug 10 is located directly above the installation block 8, forming an integral combination of oil and water welded aluminum heat exchanger assembly; the double water tank cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com