Discontinuous flow-preventing high-pressure hose and production process thereof

A high-pressure hose and production process technology, applied in the hose field, can solve problems such as easy collapse, affect normal work, and small bending radius of the pipe, and achieve the effects of improving pressure resistance, enhancing adhesion, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

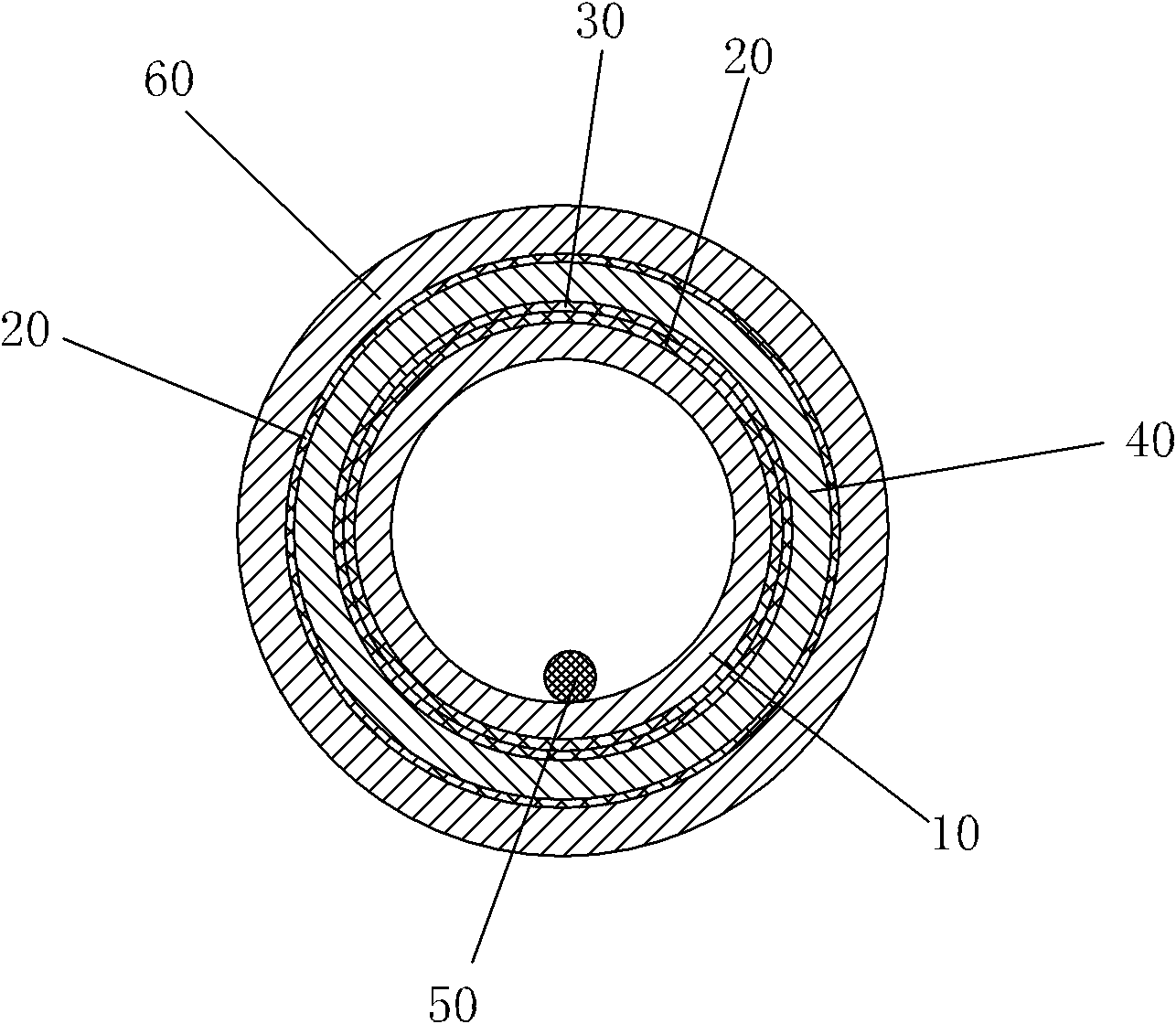

[0027] The present invention will be further described below with specific embodiment, see Figure 1-2 :

[0028] The production process of anti-stop flow high-pressure hose, the specific steps are as follows:

[0029] (1) Mixing: high-speed mixing of raw materials and various additives;

[0030] (2) Cooling: cooling the mixed material after mixing;

[0031] (3) Granulation: carry out twin-screw granulation to the mixed material after cooling;

[0032] (4) Inner tube 10 is extruded: Extrude the inner tube 10 with the extruder extruding the mixed material after granulation, wherein the inner surface of the inner tube 10 is extruded with anti-stop flow protruding strip 60 at one time, and 10 outside the inner tube Adhesive layer 20 is arranged on the surface to form a semi-finished product;

[0033] (5) Closing of semi-finished products: close the market after cooling the semi-finished products;

[0034] (6) Twisted yarn layer is set: inflate the inner tube of the semi-fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com