Single-row reciprocating piston type rotor engine

A rotary engine and reciprocating piston technology, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve the problems of increased blow-by gas between the mixture chambers, accelerated decline in sealing performance, and short service life, and can eliminate high-speed inertia. The effect of shock vibration, elimination of crankshaft torsional vibration, and increased work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

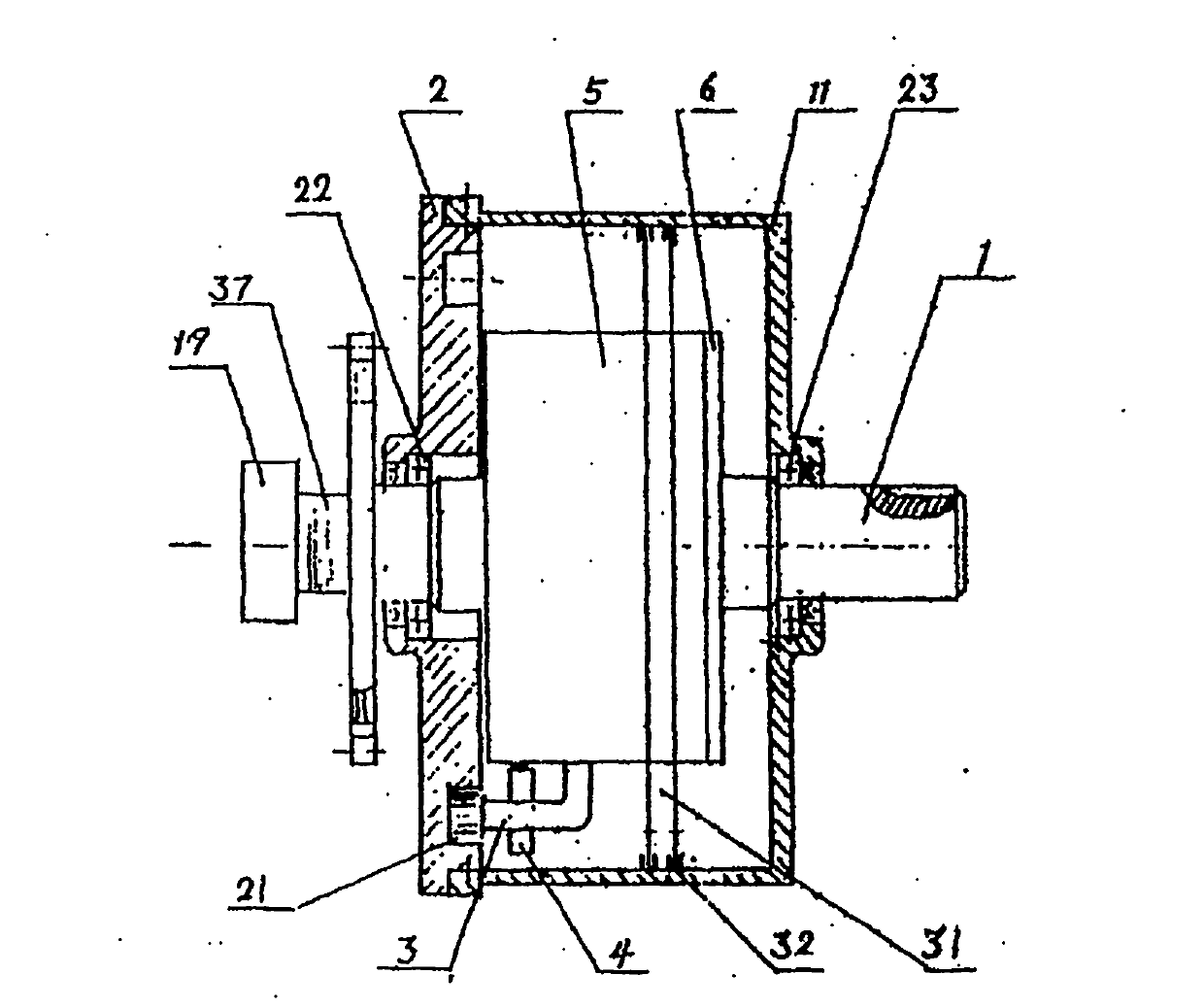

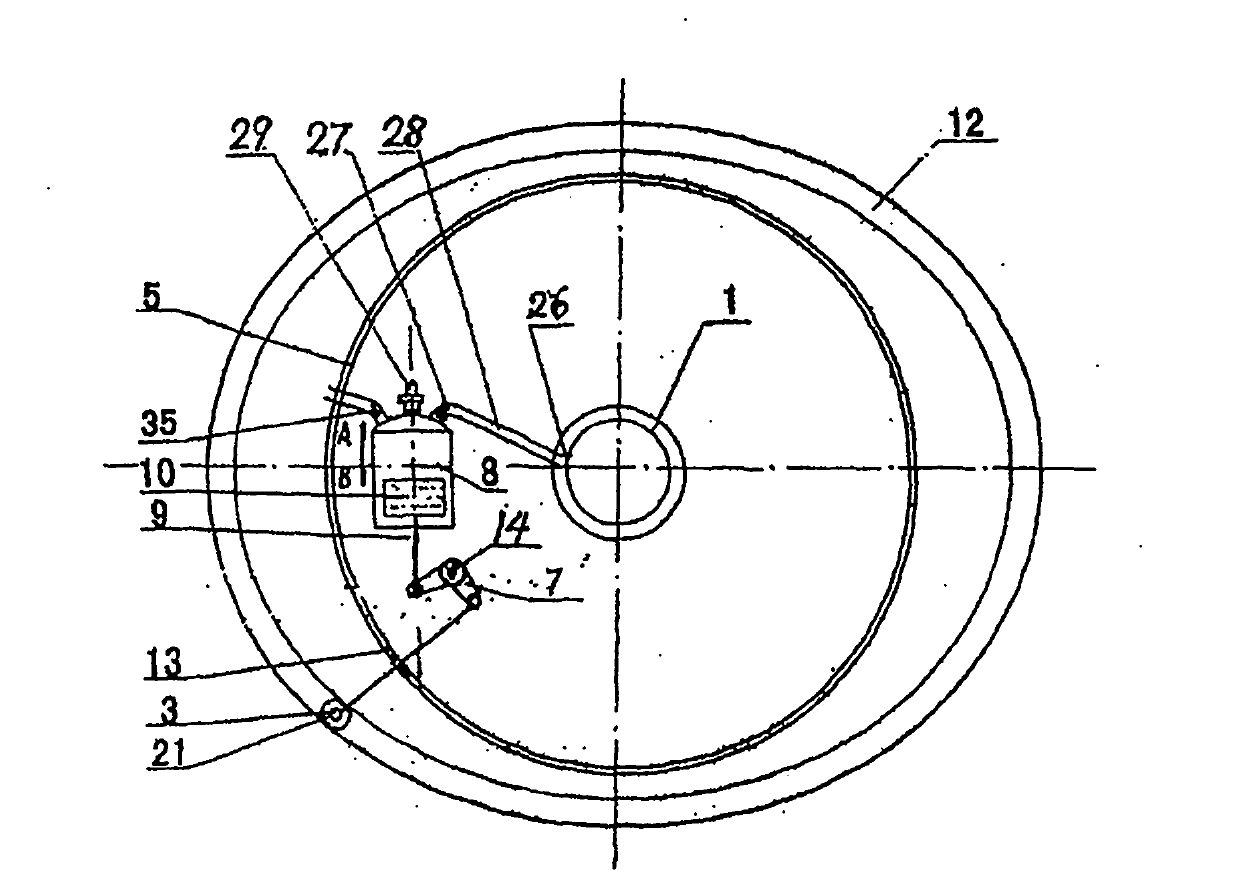

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

[0029] Design elliptical track groove (major axis - short axis) ÷ 2 = piston stroke S

[0030] Set the major axis of the elliptical orbital groove (12) of the elliptical orbital groove disc body at the vertical position, the lower apex is 0°, and rotate clockwise. When the starter drives the main shaft (1) to rotate, the cylindrical rotary cylinder The body (5) drives the positioning U-shaped fork (4), the transmission connecting rod (3), and the bearing at the lower end of the connecting rod (21) to rotate together synchronously. Due to the specific structural design of the elliptical track groove, the bearing (21) drives the transmission connecting rod (3 ) of the trajectory changes periodically with the position of the major and minor axes of the elliptical track groove (12), doing centripetal reciprocating motion. When 0-90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com