Method for extracting rose essential oil from fresh rose flowers

A technology for rose essential oil and flowers, which is applied in the directions of essential oils/spices, fat production, etc., can solve the problems of high loss of low molecular components of rose essential oil, large equipment investment, and low oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment and steps of the present invention are:

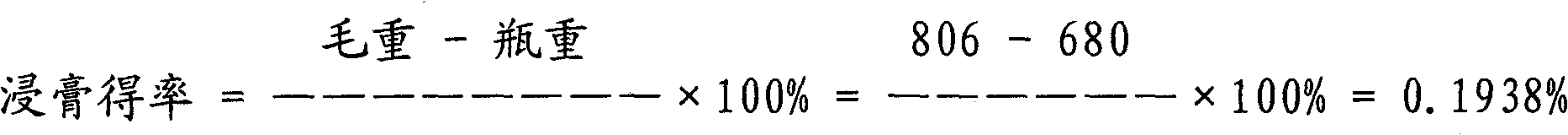

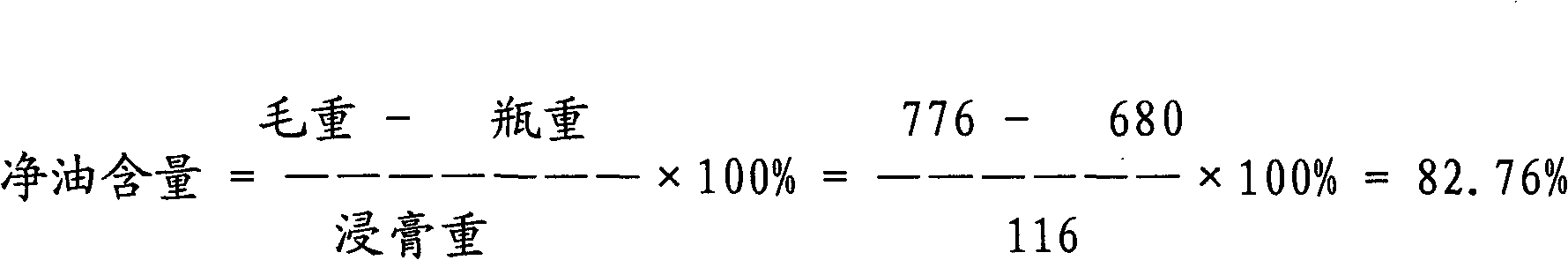

[0040] 1. Extraction Weigh 5kg of stored Fenghua rose flowers into a 75L stainless steel bucket, add 4 times the solvent (volume ratio), stir every half an hour, extract for more than 2 hours, then filter, and the filtrate is used for concentration. Add 4 times more solvent to the slag for the second extraction, pour the second extract into another plastic bucket containing 5Kg roses, add 4 times more solvent to the flower slag, and extract four times in this way. The flower residue after four extractions was discarded after recovering the solvent.

[0041] 2. Filtration Use coarse filter paper to filter the first extract, and the filtrate is used for concentration.

[0042] 3. Atmospheric pressure concentration Use self-made 25L stainless steel equipment to carry out atmospheric pressure concentration, put the filtrate into the distillation tank, heat it with an induction cooker with a heating power of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com