Copolyester and application thereof

A technology of copolyester and diol, applied in the field of copolyester, can solve the problems of poor polyester heat resistance, unfavorable spinning smoothly, environmental pollution, etc. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add bishydroxyethyl terephthalate into the esterification reaction tank, keep the temperature at 250°C and the pressure at 1.2×10 5 Pa, 8.25kg of high-purity terephthalic acid and 3.54kg of ethylene glycol slurry were gradually added to the esterification reaction layer within 4 hours, and then the esterification reaction was carried out for 1 hour. Finally, 10.2 kg was taken from the obtained esterification reaction product and added to the polycondensation reaction layer.

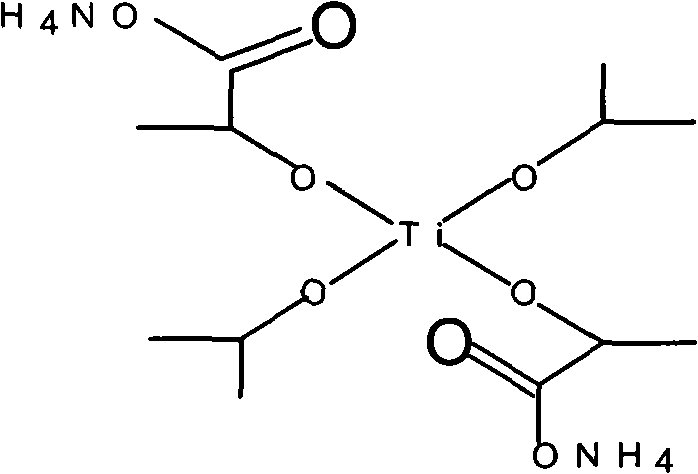

[0037] The esterification reaction product is kept at 250 DEG C, under normal pressure, adds the 2-methyl-1 that is equivalent to the whole glycol 10mol% amount of gained polyester and stirs for 30 minutes (2 in the whole reaction process) The ratio of the moles of basic acid to the sum of the moles of ethylene glycol and 2-methyl-1,3 propanediol is 1:1.24). Then add phosphorus element with respect to the phosphoric acid of copolyester 18ppm, add titanium oxide particle amount after 5 minutes and ...

Embodiment 2

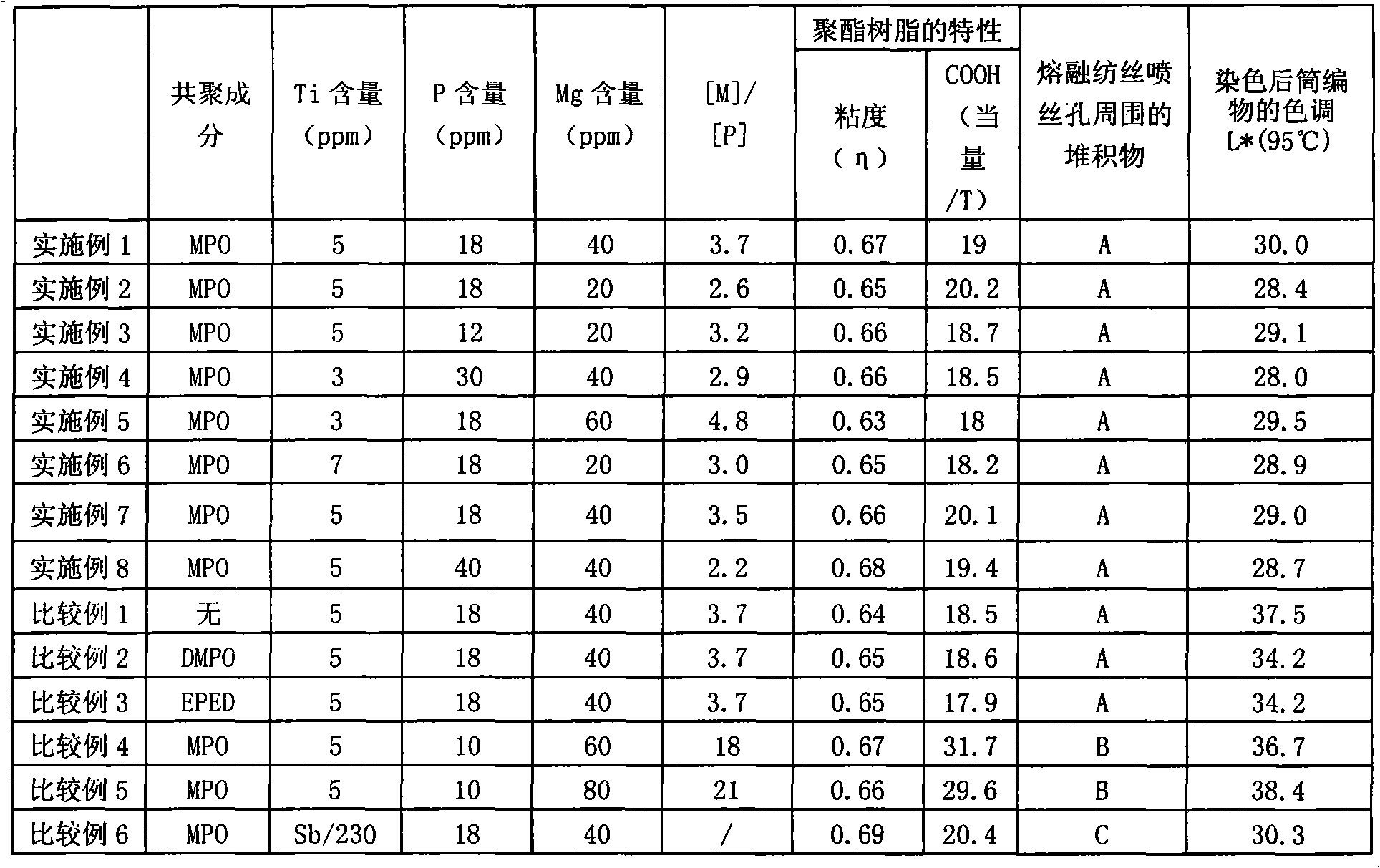

[0050] Change the addition of magnesium element in magnesium acetate to 20ppm, and the rest of the conditions are the same as in Example 1. The copolyester obtained has excellent heat resistance, [M] / [P]=2.6; during melt spinning, almost no Deposits around the spinneret hole and filter pressure increase during spinning. The obtained silk was tube-knitted, and the tube-knitted fabric was dyed at a temperature of 95° C., and the measured L* value was 28.4.

Embodiment 3

[0052] The addition of phosphorus element in phosphoric acid is changed into 12ppm, the addition of magnesium element in magnesium acetate is changed into 20ppm, all the other conditions are with embodiment 1, and the copolyester heat resistance that makes is excellent, [M] / [P]= 3.2; During melt spinning, deposits around the spinneret hole and increase in filter pressure during spinning were hardly observed. The obtained yarn was tube-knitted, and the tube-knitted fabric was dyed at a temperature of 95° C., and the L* value was measured to be 29.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com