Bead suspension polymerization method for methyl methacrylate

A technology of methyl methacrylate and suspension polymerization, which is applied in the field of preparation of dentifrice and dental tray powder, and can solve the problems of undisclosed PMMA particle preparation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A 1000ml glass four-necked flask, a glass reflux condenser, a magnetic electric stirrer (JB50-D type, manufactured by Shanghai Specimen Model Factory), a glass thermometer, and an electric heating mantle (DRT-TW type, manufactured by Zhengzhou Changcheng Technology Industry and Trade Co., Ltd.) connect.

[0051] Prepare the aqueous phase at room temperature: 432 g of deionized water, 1 g of polyvinylpyrrolidone K90 (manufactured by Hangzhou Nanhang Science and Technology Development Co., Ltd.), 0.02 g of polyvinylpyrrolidone K30 (manufactured by Hangzhou Nanhang Science and Technology Development Co., Ltd.), sodium polyacrylate (Henan Nanhang Science and Technology Development Co., Ltd.) Xinxiang Zhonghe Resin Co., Ltd.) 2.5g, hydroxyethyl cellulose H2000 (manufactured by Guangzhou Bangle Chemical Raw Materials Co., Ltd.) 0.1g, ammonium thiocyanate (manufactured by Yixing No. 2 Chemical Reagent Factory) 0.4g, mixed and fully Stir until the aqueous solution is transparen...

Embodiment 2-4

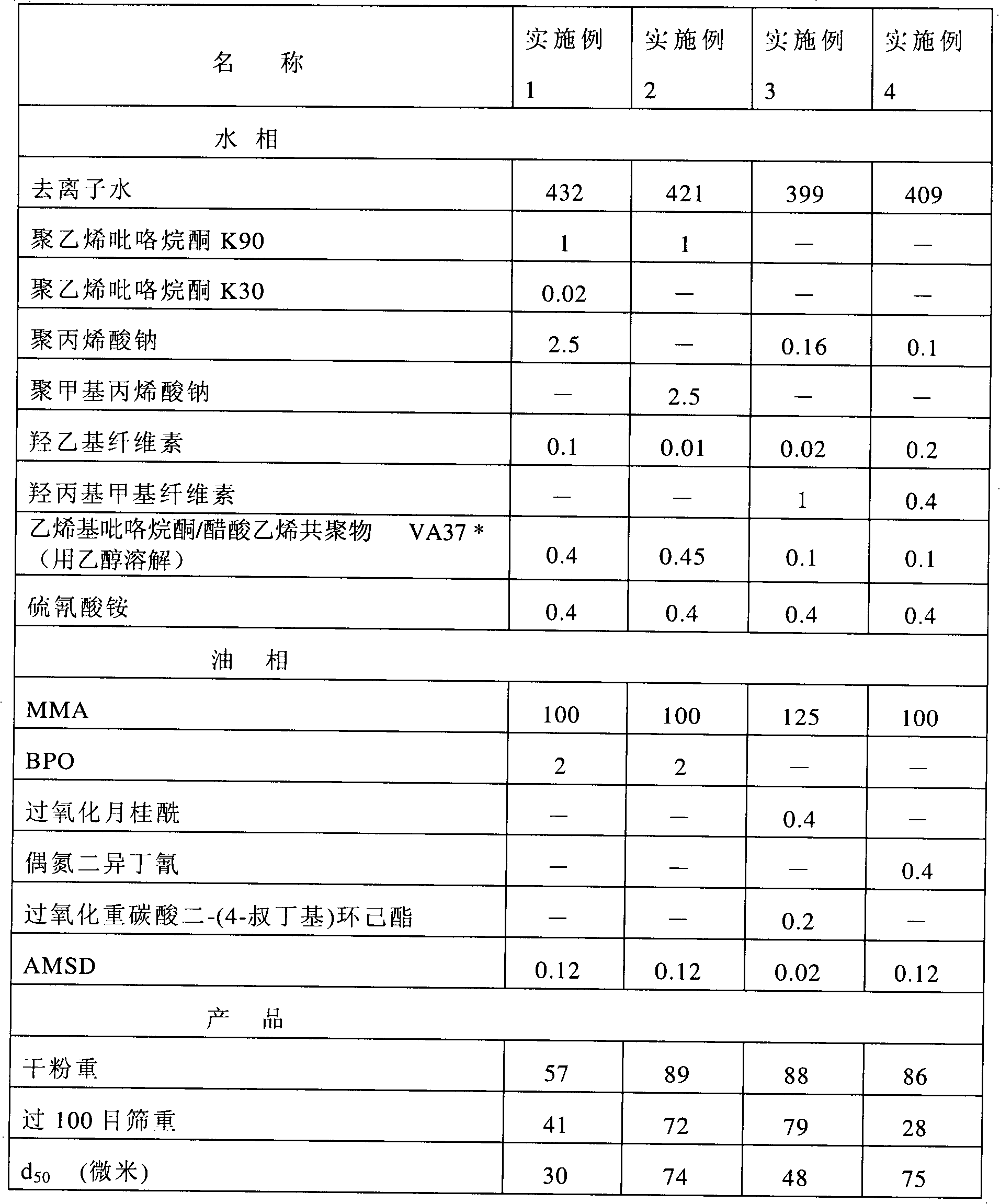

[0056] The samples of Examples 2-4 were prepared according to the method of Example 1. The reagents used and the samples prepared are listed in Table 3.

[0057] Table 3 The reagents used in Examples 1 to 4 and the samples prepared Unit: gram

[0058]

[0059] *It can be added in the middle of the reaction, or added to the water phase when preparing the water phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com