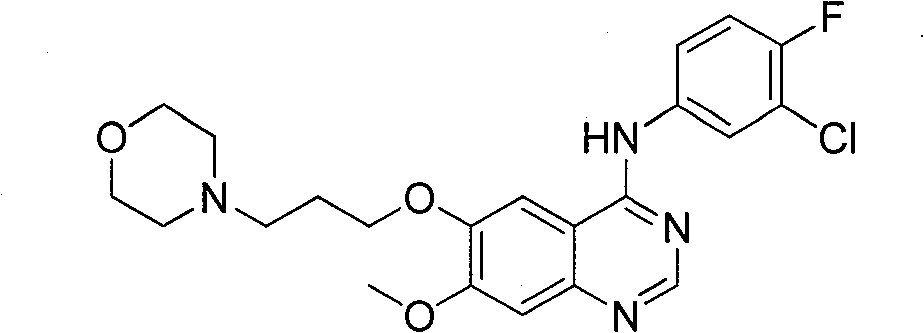

Method for preparing gefitinib

A technology of gefitinib and methoxy, which is applied in the field of medicinal chemistry, can solve the problems of many by-products, low yield, and many side reactions, and achieve the effects of less waste, high yield, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

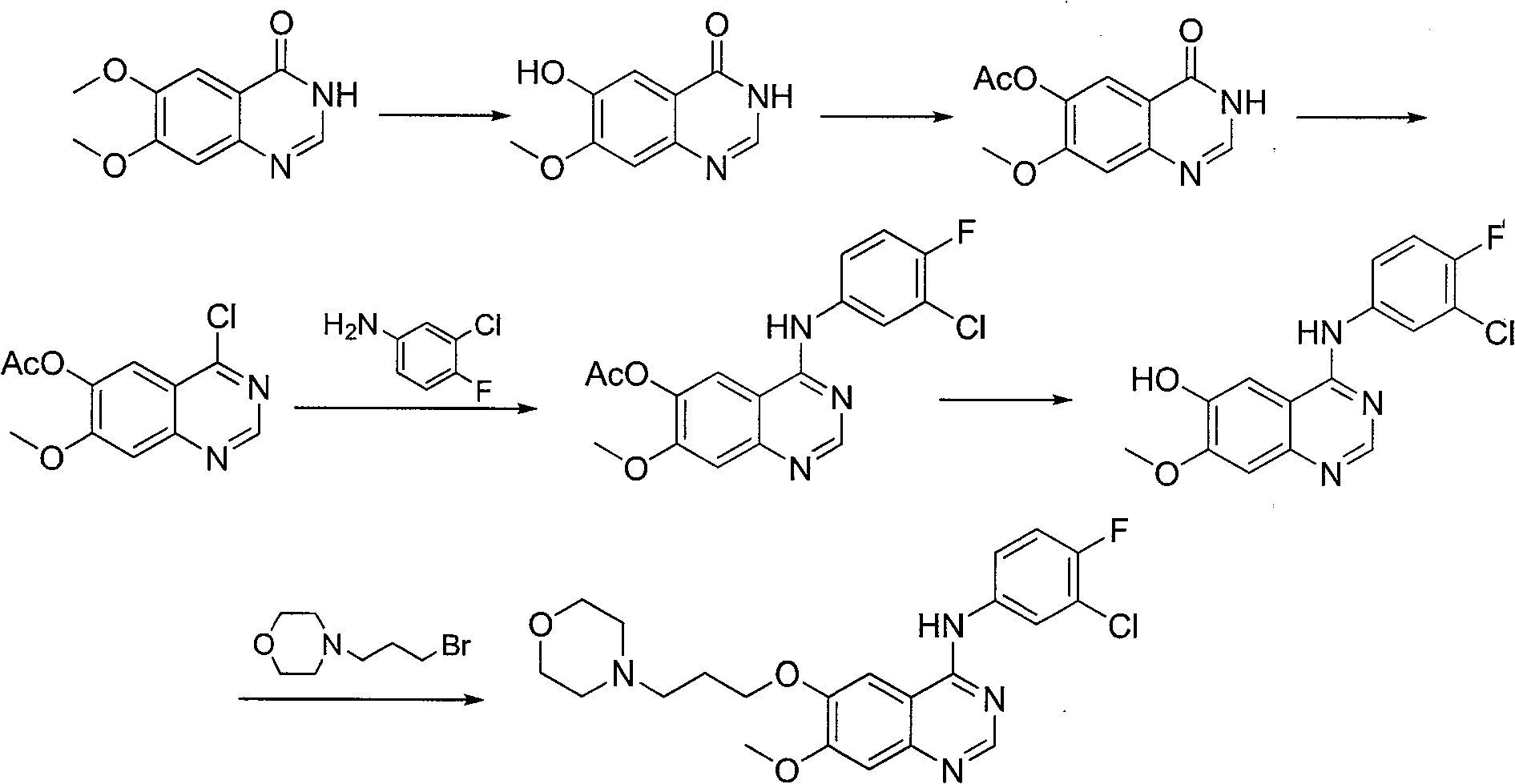

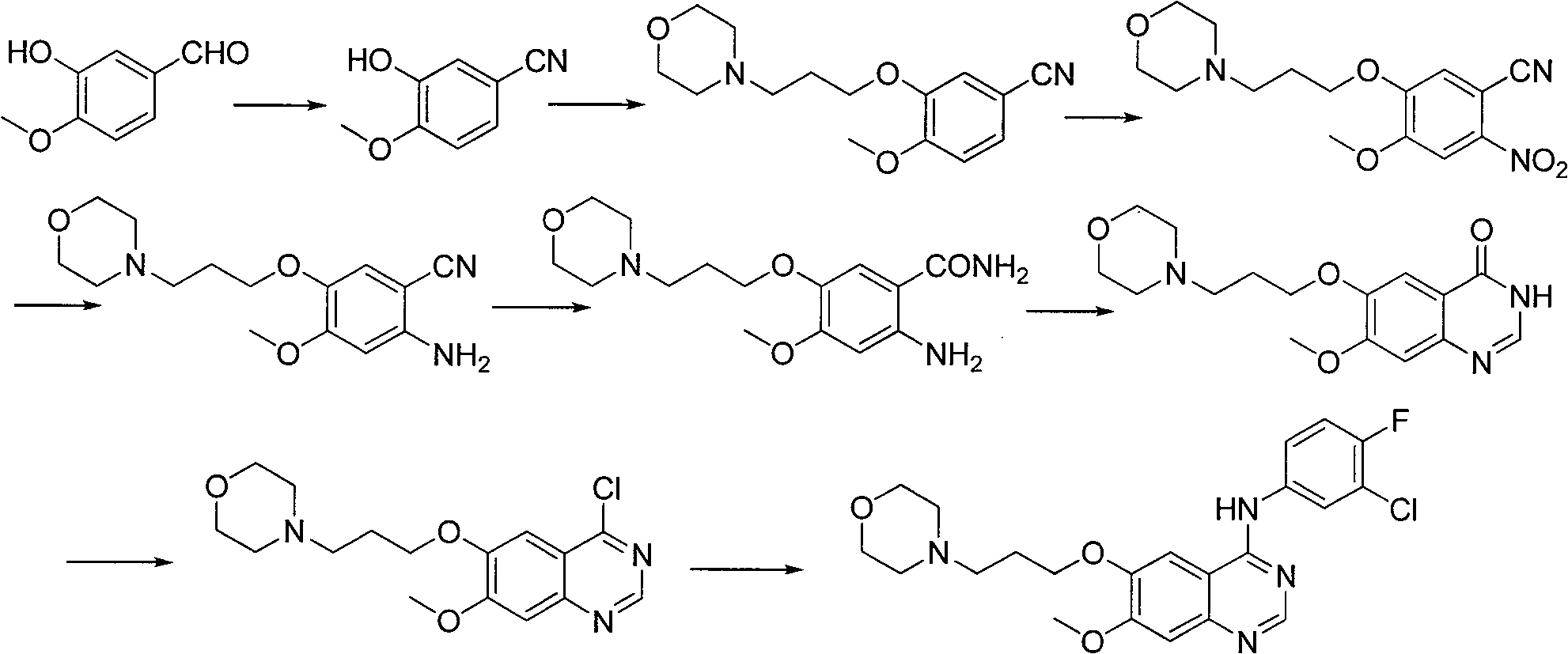

Method used

Image

Examples

example 1

[0048] The first step: the preparation of 3,4-dimethoxy-6-nitrobenzoic acid (3):

[0049] Place the 2L three-necked flask in an ice bath, and add 1100ml HNO to the bottle 3 (65%~68%), insert a thermometer and a mechanical stirring device, add 200g of 3,4-dimethoxybenzoic acid (2) in small batches under stirring, about 1h, after adding, continue to stir for 15min, and then Pour it into a container containing 10L of cold water under stirring. After adding, continue to stir for 10 minutes, filter, suck dry, then beat with 5L cold water for a few minutes, filter, and drain as much as possible. The crude product was dried in a vacuum oven at 50° C. for 48 hours to obtain 237 g of crude product. It was recrystallized from 95% ethanol to obtain 199 g of a yellow solid with a yield of 80%.

[0050] Second step: the preparation of 2-nitro-4-methoxy-5-hydroxybenzoic acid (4):

[0051] 199g of 3,4-dimethoxy-6-nitrobenzoic acid (3) was added to 1L of 20% NaOH solution, heated and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com