Processing and forming method for workpieces made of blocky metal glass or composite material of blocky metal glass

A technology of bulk metal and composite materials, which is applied in the field of manufacturing bulk metallic glass or its composite material workpieces, can solve the problems of unsuitability for mass industrial production, product size and shape restrictions, complex processing equipment, etc., to eliminate defects, The effect of low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

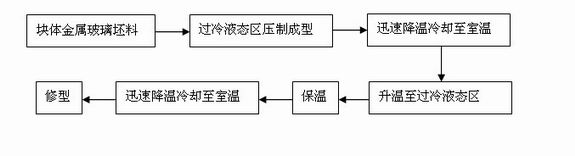

[0023] Such as figure 1 Said, this example uses Zr 55 Cu 30 Al 10 Ni 5 (Atomic percentage) The processing and molding method of the bulk metallic glass workpiece is an example, and the specific steps are as follows:

[0024] (1) Blank selection process:

[0025] Zr obtained by suction casting 55 Cu 30 Al 10 Ni 5 Machining of bulk metallic glass to slabs of the desired size;

[0026] (2) Molding process: According to the requirements of the workpiece, the shaped mold cavity is made, and the bulk metallic glass blank is heated to 430°C in the supercooled liquid region at a heating rate of 20K / min. The strain rate of 2s-1 is used for press forming, and the pressure is greater than 50MPa to form the blank;

[0027] (3) Heat treatment process: pressurize the molded bulk metallic glass workpiece gradually to a stable pressure of 100-400MPa, and then heat it up to a selected temperature of 430°C in the supercooled liquid state of the metallic glass material. Cool down afte...

Embodiment 2

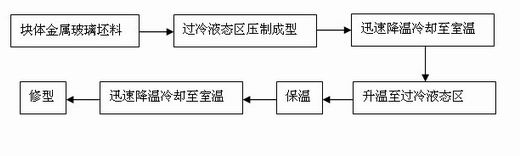

[0030] In this example, Zr 55.9 Cu 18.6 Ta 8 Al 7.5 Ni 10 (Atomic percentage) The processing and molding method of the bulk metallic glass composite material workpiece is taken as an example, and the specific steps are as follows:

[0031] (1) Blank selection process:

[0032] Zr obtained by suction casting 55.9 Cu 18.6 Ta 8 Al 7.5 Ni 10 Machining of bulk metallic glass composites into slabs of required size;

[0033] (2) Molding process: According to the requirements of the workpiece, the shaped mold cavity is made, and the bulk metallic glass blank is heated to 440°C in the supercooled liquid region at a heating rate of 20K / min. -2 the s -1 The strain rate is used for press forming, and the pressure is greater than 50MPa to form the blank;

[0034](3) Heat treatment process: pressurize the molded bulk metallic glass workpiece gradually to a stable pressure of 100-400MPa, and then heat it up to a selected temperature of 440°C in the supercooled liquid range of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com