Method for processing fragile material substrate

A technology of brittle material substrates and processing methods, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve problems such as narrow process tolerances, achieve wide process tolerances, reduce the uncontrollable direction of travel, and easily break The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0061] First, an example of a substrate processing apparatus used for carrying out the processing method of the present invention will be described.

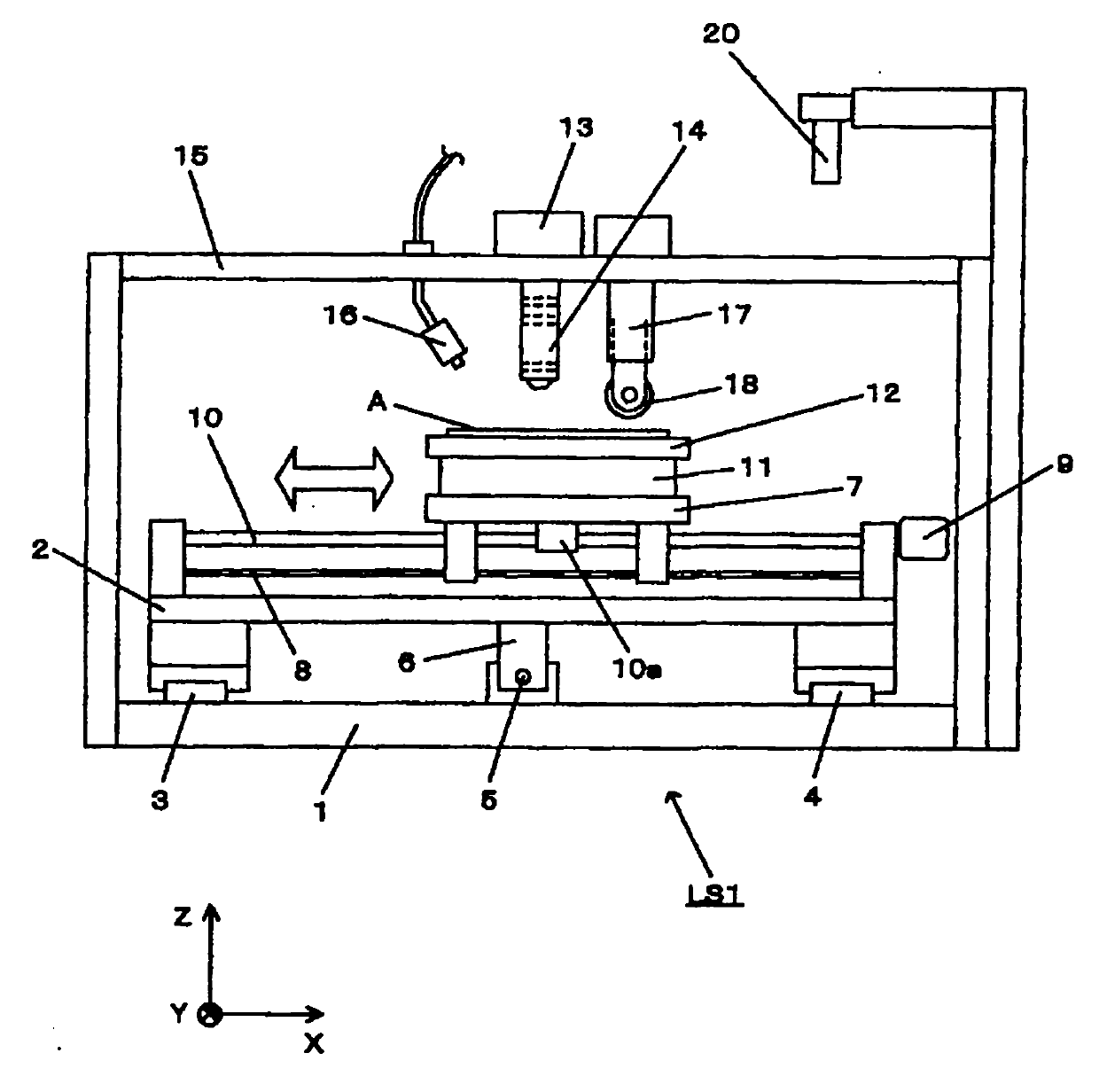

[0062] figure 1 It is a schematic configuration diagram of a substrate processing apparatus LS1 capable of implementing the processing method of the present invention. Here, the case of processing a glass substrate will be described as an example, but the same applies to substrates made of brittle materials such as silicon substrates.

[0063] First, the overall configuration of the substrate processing apparatus LS1 will be described. There is a pair of guide rails 3, 4 arranged in parallel on the horizontal stand 1. figure 1 The slide table 2 reciprocates in the front-back direction of the paper (hereinafter referred to as the Y direction). And it is formed as follows: between the two guide rails 3, 4, a lead screw 5 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com