Multiple-effect viscosity depressant for exploiting thickened oil

A technology of viscosity reducer and viscous oil, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult to control emulsion stability, poor biochemical degradation performance, and large amount of water, and achieve moderate stability. , the effect of improved recovery and strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

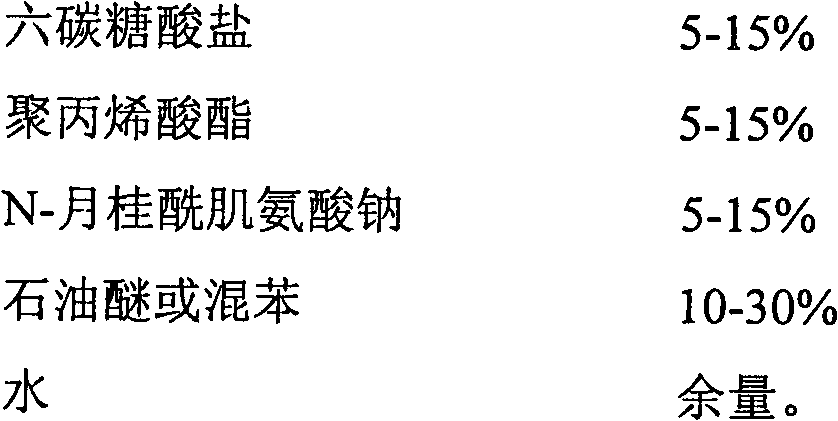

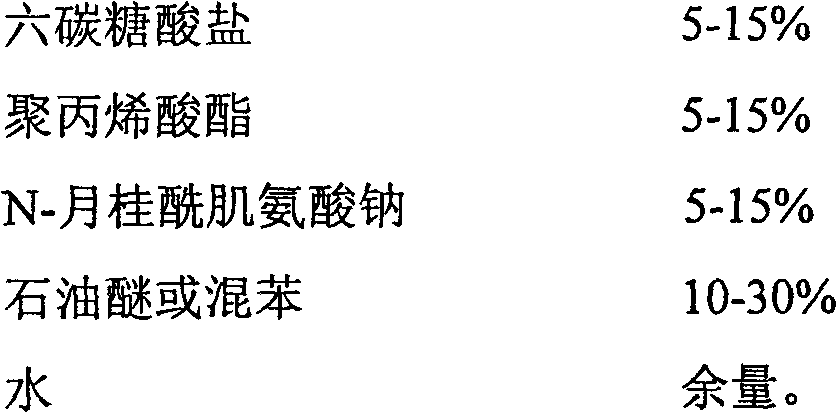

[0025] 1. According to the mass ratio, it is 8% iron gluconate, 5% block polymer of ethyl acrylate and butyl acrylate, 10% sodium N-lauroyl sarcosinate, 25% petroleum ether, and 52% water. The several raw materials are mixed and stirred to obtain a multi-effect viscosity reducer for heavy oil recovery. Using Karamay Oilfield as a viscosity reduction test for heavy oil, the viscosity reduction rate reached 98%

[0026] 2. According to the mass ratio, it is 10% of iron gluconate, 10% of block polymer of ethyl acrylate and butyl acrylate, 15% of sodium N-lauroyl sarcosinate, 30% of mixed benzene, and 35% of water. The several raw materials are mixed and stirred to obtain a multi-effect viscosity reducer for heavy oil recovery. Viscosity reduction test for heavy oil in Karamay Oilfield, the viscosity reduction rate reached 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com