Thermoplastic crack resistant type low smoke zero halogen flame-retardant polyolefin cable sheath material and preparation method thereof

A cable sheath material and anti-cracking technology, applied in the direction of insulating cables, plastic/resin/wax insulators, cables, etc., can solve the problem of easy cracking of thermoplastic low-smoke halogen-free flame-retardant sheath materials, and achieve easy recycling , Good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

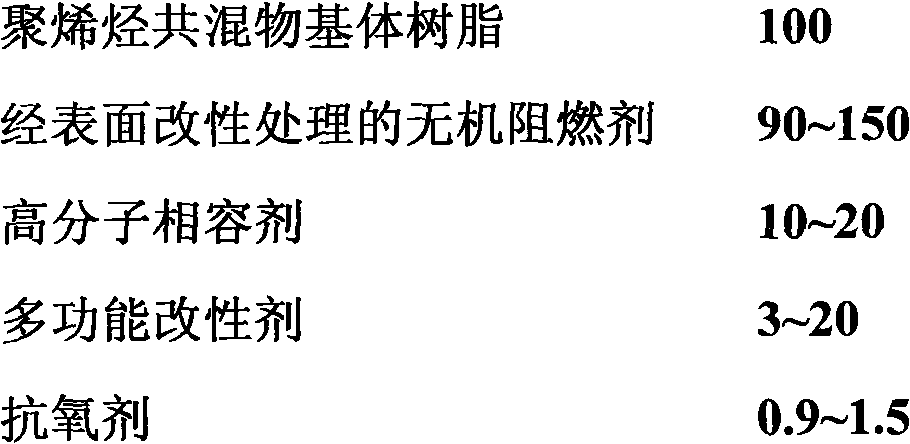

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The polyolefin blend is a blend system of EVA and VLDPE in a ratio (by weight) of 8:2 as a matrix resin. MDH is used as the inorganic flame retardant, and a silane coupling agent (accounting for 1% of the amount of MDH) is used for surface modification. The polymer compatibilizer adopts EVA-g (ethylene-vinyl acetate grafted maleic anhydride). The mass composition of the multifunctional modifier is: 25% of silicone rubber, 23% of ethylene-vinyl acetate copolymer, 22% of silicon dioxide, 10% of magnesium oxide, and 20% of calcium stearate. Antioxidant adopts compound antioxidant B215. The processing aid adopts zinc stearate.

Embodiment 2

[0025] Embodiment 2: The polyolefin blend is a blend system of EVA and VLDPE in a ratio of 8:2 as the matrix resin. MDH is used as the inorganic flame retardant, and a silane coupling agent (accounting for 1% of the amount of MDH) is used for surface modification. The polymer compatibilizer adopts EVA-g (ethylene-vinyl acetate grafted maleic anhydride). The specific composition of the multifunctional modifier is: 22% of silicone rubber, 25% of ethylene-vinyl acetate copolymer, 25% of silicon dioxide, 8% of magnesium oxide, and 20% of zinc stearate. Antioxidant uses antioxidant (1010). The processing aid uses polymer wax.

Embodiment 3

[0026] Example 3: The polyolefin blend is a blend system of EVA and LLDPE at a ratio of 9:1 as a matrix resin. LDHS is used as the inorganic flame retardant, and stearic acid (accounting for 1.5% of the amount of LDHS) is used for surface modification. Polyethylene grafted maleic anhydride is used as polymer compatibilizer. The specific composition of the multifunctional modifier is: 20% of silicone rubber, 25% of ethylene-vinyl acetate copolymer, 25% of silicon dioxide, 10% of zinc oxide, and 20% of zinc stearate. Antioxidant uses antioxidant (1010). The processing aid uses polymer wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com