Tert-butyl carbamate derivative and preparation method and application thereof

A technology of isobutyl chloroformate and serine, applied in the fields of organic chemistry and medicinal chemistry, can solve problems such as large loss, great difficulty, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

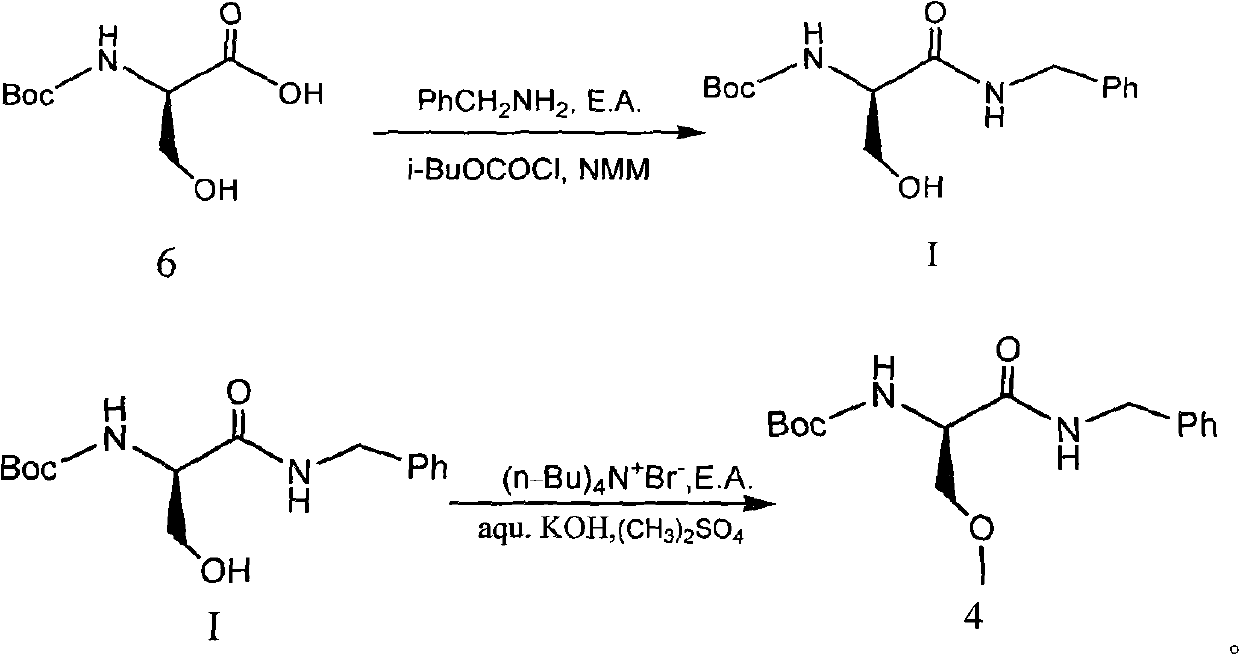

Method used

Image

Examples

Embodiment 1

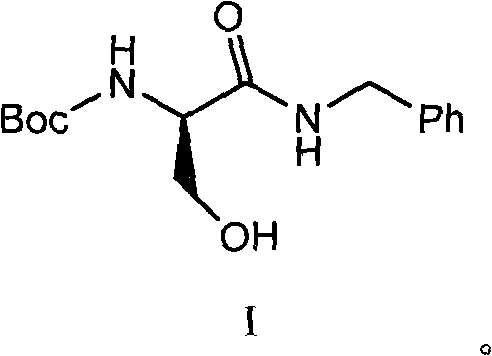

[0065] 29.48g benzylamine was dissolved in 50g anhydrous ethyl acetate to prepare a solution for use. In a 1000ml four-necked round bottom flask, 51.3g of compound 6 (N-BOC-D-serine) was dissolved in 400ml of anhydrous ethyl acetate, the temperature was lowered to -10℃, and 27.83g of N-methylmorpholine and 37.59g isobutyl chloroformate. After the addition is complete, continue the reaction at -15~-10°C for 2 hours. Then add dropwise the ethyl acetate solution of benzylamine that has been prepared. After the dropwise addition is completed, the temperature is raised to 10-15°C and reacted for 2 hours. After the reaction is completed, add water, extract the phases, wash the organic phase with dilute hydrochloric acid and brine, evaporate the solvent under reduced pressure, crystallize with hexane / ethyl acetate = 8 / 1, and dry to obtain 66.3 g of the product with a yield of 90.2% .

[0066] The structure data is as follows: 1H NMR (400MHz, DMSO- ) ppm: 1.38 (s, 9H), 3.58 (m, 2H), ...

Embodiment 2

[0068] 34.84g benzylamine was dissolved in 60g anhydrous ethyl acetate to prepare a solution for use. In a 1000ml four-necked round bottom flask, 51.3g of compound 6 (N-BOC-D-serine) was dissolved in 400ml of anhydrous ethyl acetate, the temperature was lowered to -20℃, and 32.99g of N-methylmorpholine and 44.42g isobutyl chloroformate. After the addition is complete, continue the reaction at -15~-10°C for 2 hours. Then add dropwise the ethyl acetate solution of benzylamine that has been prepared. After the dropwise addition is completed, the temperature is raised to 15-20°C and reacted for 2 hours. After the reaction is complete, add water, extract the phases, wash the organic phase with dilute hydrochloric acid and brine, evaporate the solvent under reduced pressure, crystallize with hexane / ethyl acetate = 8 / 1, and dry to obtain 66.9 g of product with a yield of 91.0% .

Embodiment 3

[0070] 40.20 g benzylamine was dissolved in 70 g anhydrous ethyl acetate to prepare a solution for use. In a 1000ml four-necked round bottom flask, 51.3g of compound 6 (N-BOC-D-serine) was dissolved in 400ml of anhydrous ethyl acetate, the temperature was reduced to 0℃, and 38.06g of N-methylmorpholine and 51.25 were added dropwise successively. g Isobutyl chloroformate. After the dropwise addition is completed, continue the reaction at 0-5°C for 2 hours. Then add dropwise the ethyl acetate solution of benzylamine that has been prepared. After the dropwise addition is completed, the temperature is raised to 10-15°C and reacted for 2 hours. After the reaction is complete, add water, extract the phases, wash the organic phase with dilute hydrochloric acid and brine, evaporate the solvent under reduced pressure, crystallize with hexane / ethyl acetate = 8 / 1, and dry to obtain 68.4 g of product with a yield of 93.1% .

[0071] Compound 4, the synthesis of (R)-2-(amino-Boc)-N-benzyl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com