Method for synthesizing graphene film material

A graphene film and film material technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of difficult realization of the production process of graphene film, harsh reaction conditions, etc., to achieve low cost, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

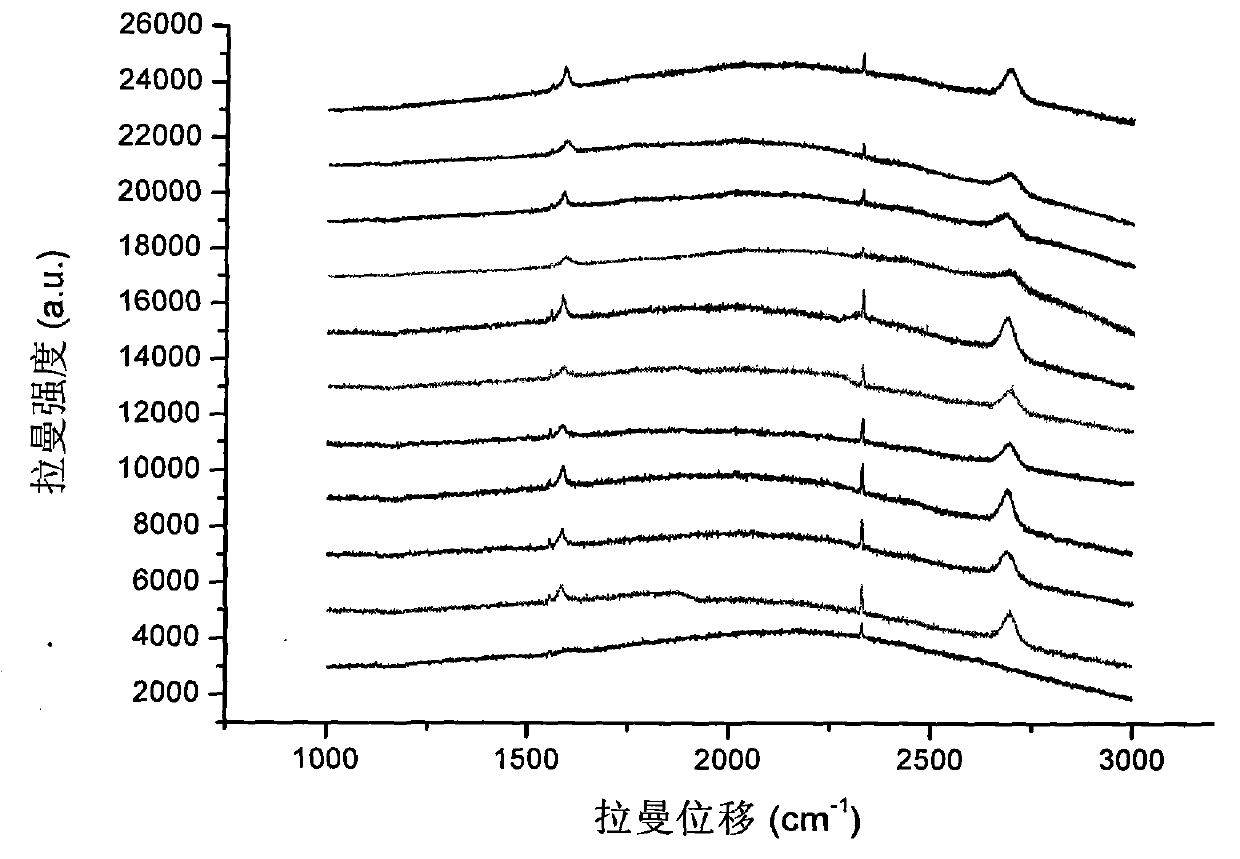

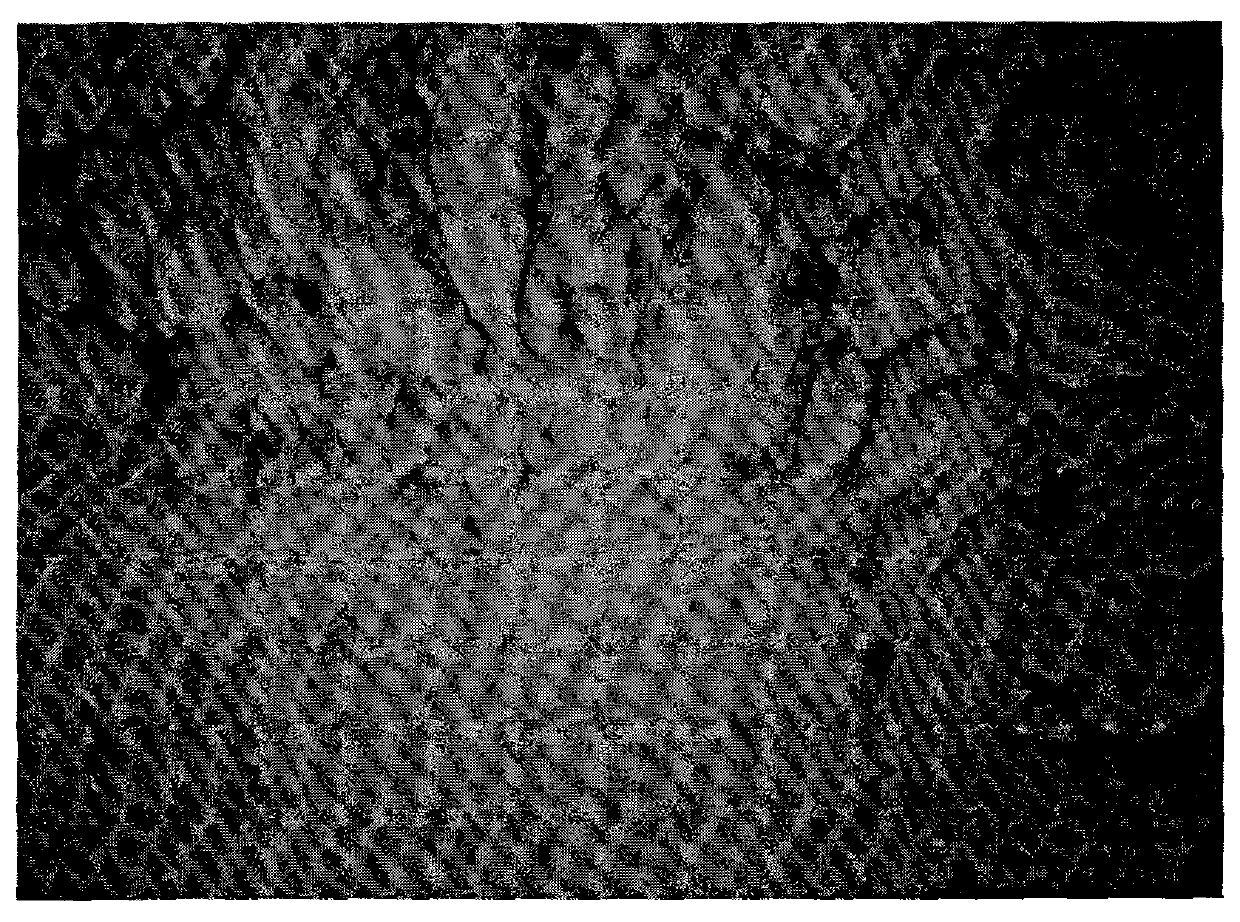

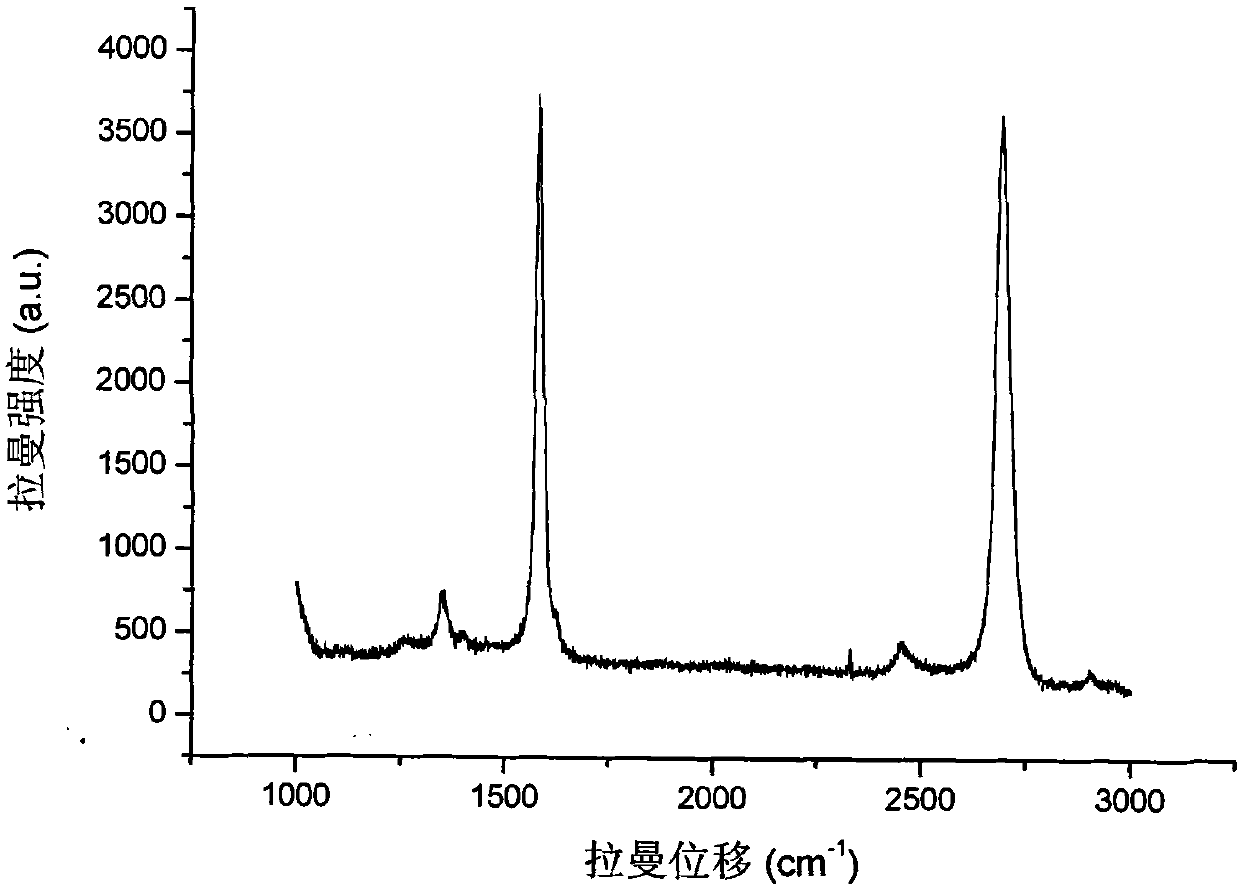

Embodiment 1

[0032] Follow the preparation process. First, the copper substrate was soaked in acetic acid at a constant temperature of 35°C for 10 minutes, and then quickly put into a chemical vapor deposition tube furnace. Use a vacuum pump to pump the reaction tube furnace to less than 10 Pa, and then feed hydrogen gas with a flow rate of 30 sccm. When the pressure inside the tube is stabilized to about 230 Pa, start to heat up from room temperature at a rate of about 10°C / min. After rising to 120°C Keep warm for 10 minutes, continue to use the same heating rate to rise to 1000°C, start to pass methane, the flow rate is 100sccm, and the pressure is kept at about 10000Pa. Keep the temperature constant for 30 minutes, stop heating, and let the furnace body cool down naturally. When the temperature drops to 700°C, open the heating furnace box and quickly drop to room temperature. Take out the copper substrate on which the graphene film has grown and place it flat on the oxidized silicon su...

Embodiment 2

[0036] Follow the preparation process. First, the copper substrate was soaked in acetic acid at a constant temperature of 35°C for 10 minutes, and then quickly put into a chemical vapor deposition tube furnace. Use a vacuum pump to pump the reaction tube furnace to less than 10 Pa, and then feed hydrogen gas with a flow rate of 40 sccm. When the pressure inside the tube is stabilized to about 800 Pa, start to heat up from room temperature at a rate of about 10°C / min. After rising to 120°C Keep warm for 10 minutes, continue to use the same heating rate to rise to 1000 ° C, start to pass methane, the flow rate is 100 sccm, and the pressure is maintained at about 20000 Pa. Keep the temperature constant for 30 minutes, stop heating, and let the furnace body cool down naturally. When the temperature drops to 700°C, open the heating furnace box and quickly drop to room temperature. Take out the copper substrate on which the graphene film has grown and place it flat on the oxidized ...

Embodiment 3

[0038] Follow the preparation process. First, the copper substrate was soaked in acetic acid at a constant temperature of 35°C for 10 minutes, and then quickly put into a chemical vapor deposition tube furnace. Use a vacuum pump to pump the reaction tube furnace to less than 10 Pa, and then feed hydrogen gas with a flow rate of 50 sccm. When the pressure inside the tube is stabilized to about 1000 Pa, start to heat up from room temperature at a rate of about 10°C / min. After rising to 120°C Keep warm for 10 minutes, continue to use the same heating rate to rise to 1000°C, start to pass methane, the flow rate is 100 sccm, and the pressure is kept at about 40000Pa. Keep the temperature constant for 30 minutes, stop heating, and let the furnace body cool down naturally. When the temperature drops to 700°C, open the heating furnace box and quickly drop to room temperature. Take out the copper substrate on which the graphene film has grown and place it flat on the oxidized silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com