Device for synchronizing packaging wheel and swing arms of handkerchief paper packaging machine and design method

A technology for paper bags and handkerchiefs, which is applied in the field of handkerchief paper packaging machines, can solve the problems of poor rigidity of paper bags, damage of paper bags, and inability to increase the speed, and achieve the effect of simplifying the installation and debugging process, avoiding pauses, and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Detailed structure

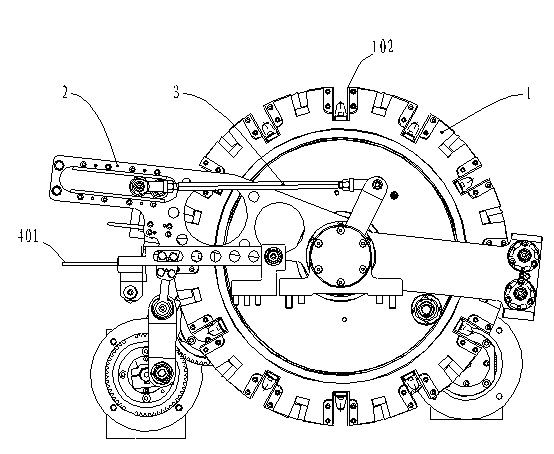

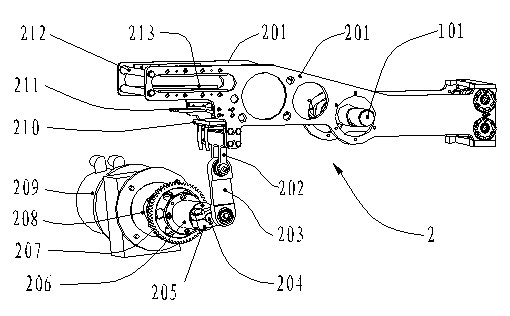

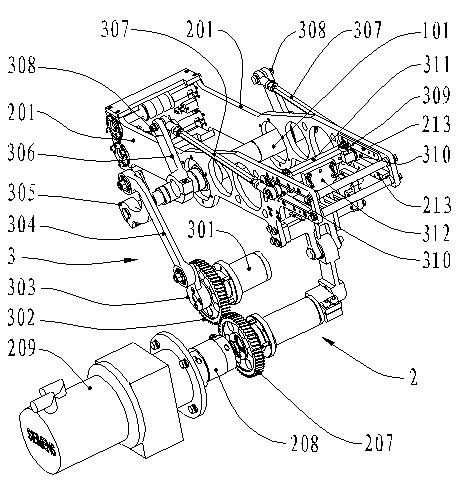

[0024] exist figure 1 Among them, the mechanical part of this synchronous control device is mainly composed of a packaging wheel 1, a swing arm mechanism 2, and a pull rod mechanism 3. The packaging wheel 1 and the swing arm mechanism 2 are coaxially installed, and the packaging wheel 1 rotates at a constant speed. The axis of the wheel 1 swings back and forth, and the pull rod mechanism 3 converts the circular motion of the servo motor 209 into a linear reciprocating motion relative to the swing arm mechanism 2 through the linkage mechanism composed of the crank 303, the connecting rod 304 and the rocker 305, and the packaging wheel 1 Every 1 / n circle of rotation, n is the number of packing wheel grooves 102 of packing wheel 1, the swing arm mechanism 2 swings back and forth once, and the pull rod mechanism 3 completes a reciprocating linear motion relative to the swing arm mechanism 2, and the supporting plate 401 moves along with the swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com