Braze welding method of slot antenna

A brazing method and slot antenna technology, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as the inability to meet the requirements of multi-layer flat slot antennas, achieve enhanced film removal effect, reduce dosage, and improve use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

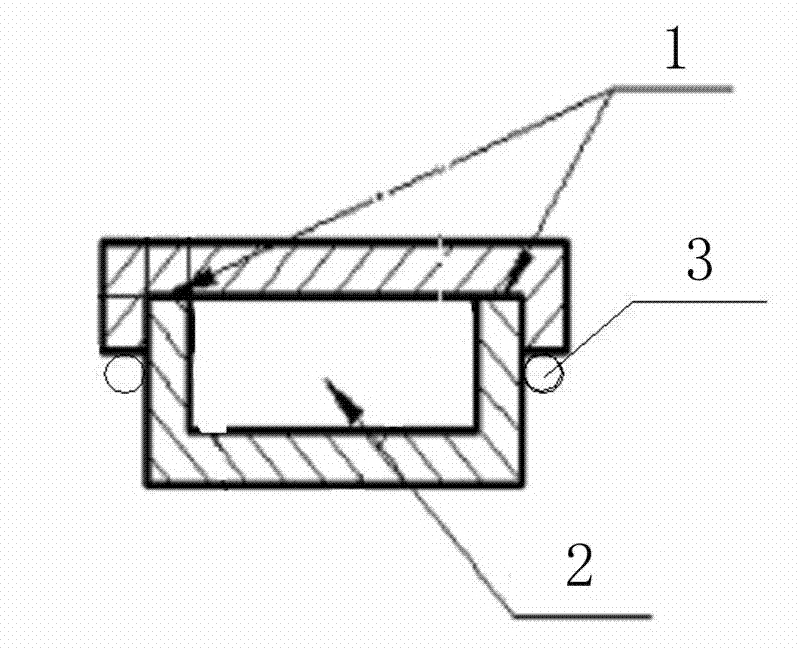

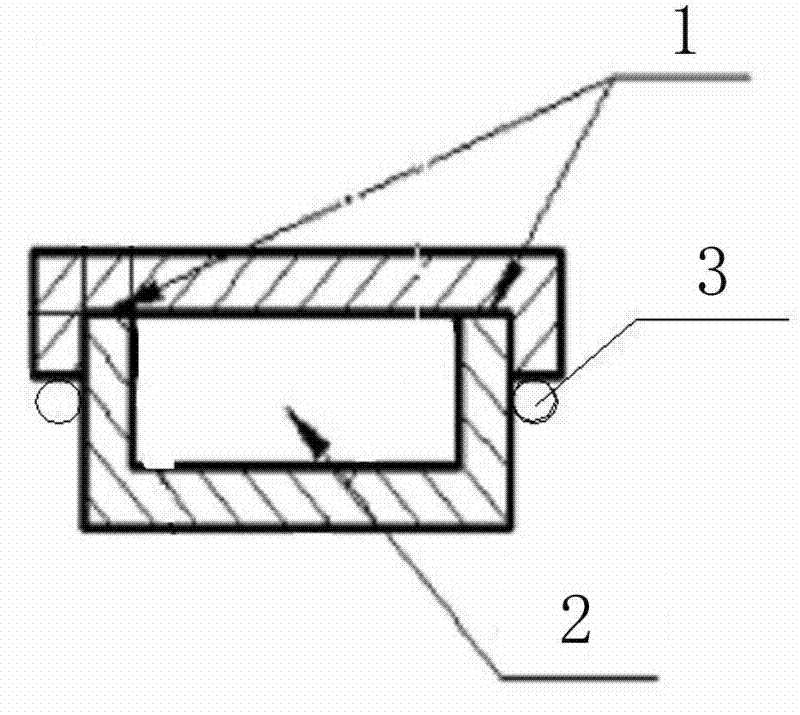

[0020] Embodiment 1: as Figure 1-2 Shown, a kind of brazing method of slot antenna comprises the following steps:

[0021] A. Assembly positioning before welding: use the gap between the mating surfaces of the parts, combine them by turning riveting and match them with positioning base plates, counterweight blocks and pins for parts positioning;

[0022] B. Solder flux fixation: place solder and flux on the positioning sinking welding step;

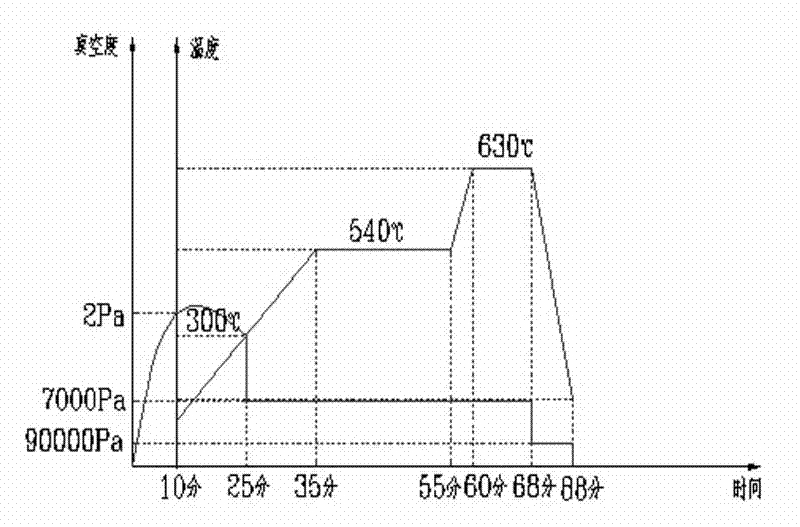

[0023] C. Welding: Put the parts into the vacuum brazing furnace, firstly evacuate the furnace, start heating when the pressure in the furnace reaches 2Pa, and after the temperature of the parts reaches 180-280°C, close the vacuum system and fill the furnace with high temperature Pure nitrogen to 4000-6000Pa, heat up to 540°C, keep warm until the temperature of the parts reaches 530°C, then continue to heat up to 630°C, keep warm until the temperature of the parts reaches 600-610°C, stop heating, fill high-purity nitrogen to 90000Pa, st...

Embodiment 2

[0025] Embodiment 2: as Figure 1-2 Shown, a kind of brazing method of slot antenna comprises the following steps:

[0026] A. Assembly positioning before welding: use the gap between the mating surfaces of the parts, combine them by turning riveting and match the positioning base plate, counterweight block and pins for parts positioning, place the assembled parts on the base plate, and place them in an appropriate position Use pressure weights;

[0027] B. Solder flux fixation: place solder and flux on the positioning sinking welding step, place the solder at the fillet weld where the two parts meet, and the solder is HF202 or HF201;

[0028] C. Welding: Put the parts into the vacuum brazing furnace, firstly evacuate the furnace, start heating when the pressure in the furnace reaches 2Pa, and after the temperature of the parts reaches 180-280°C, close the vacuum system and fill the furnace with high temperature Pure nitrogen to 4000-6000Pa, heat up to 540°C, keep warm until...

Embodiment 3

[0029] Embodiment 3: as Figure 1-2 Shown, a kind of brazing method of slot antenna comprises the following steps:

[0030] A. Assembly positioning before welding: use the gap between the mating surfaces of the parts, combine them by turning riveting and match them with positioning base plates, counterweight blocks and pins for parts positioning. The material of the base plate is required to be stainless steel, and the size around the shape is 300mm* 300mm, thickness 8-12mm, dig out 4 deep 4-8mm weight-reducing chambers, drill a number of cooling holes with a spacing of 15-20mm, and the flatness is not greater than 0.05mm. When processing parts, ensure that the inner cavity width of the waveguide cover plate is 0.02mm-0.05mm wider than the shape of the waveguide cavity. The corners need to be repaired by a fitter. Before placing the counterweight at the appropriate position on each side, ensure the assembly clearance of the welding seam.

[0031] B. Solder and flux fixation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com