Ethyl nitrite regeneration technological method and device used in diethyl oxalate production process

A technology of ethyl nitrite and diethyl oxalate, which is applied to the preparation of nitrite, separation methods, chemical instruments and methods, etc., can solve the problem of affecting the ratio of materials, low mass transfer and reaction efficiency, and long fluid residence time etc. to achieve the effect of high reaction efficiency, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

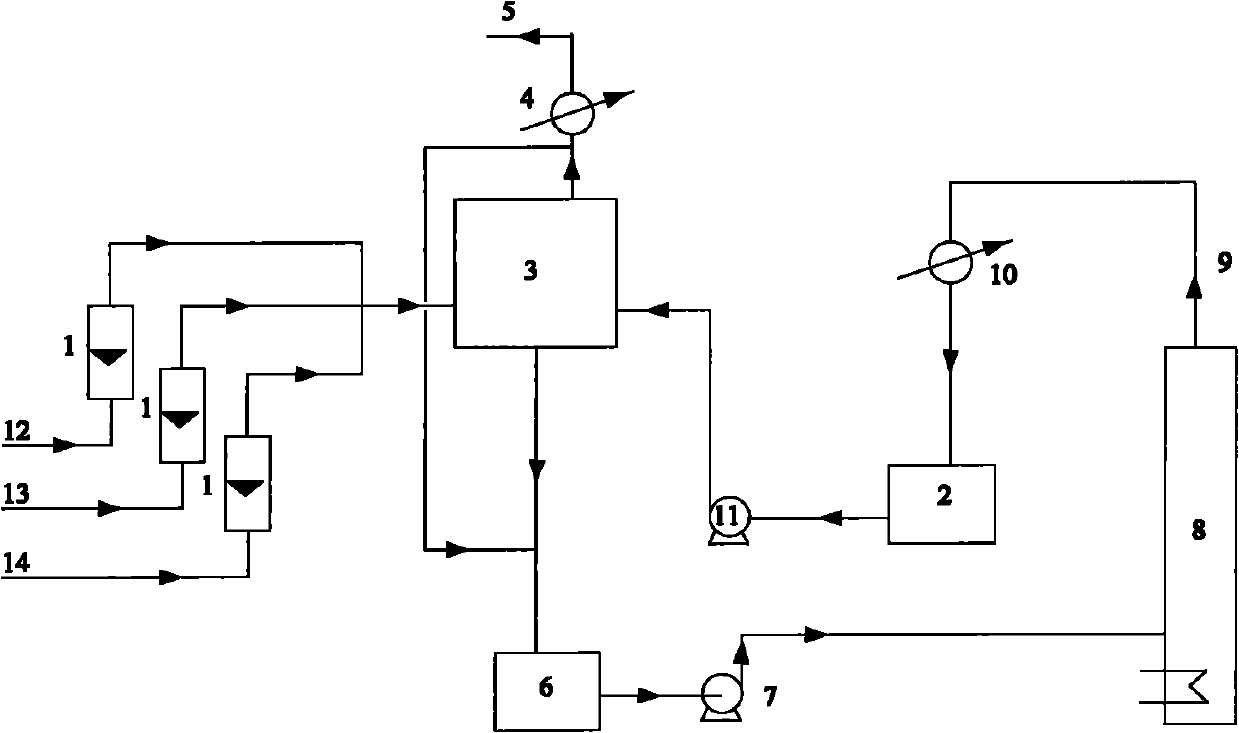

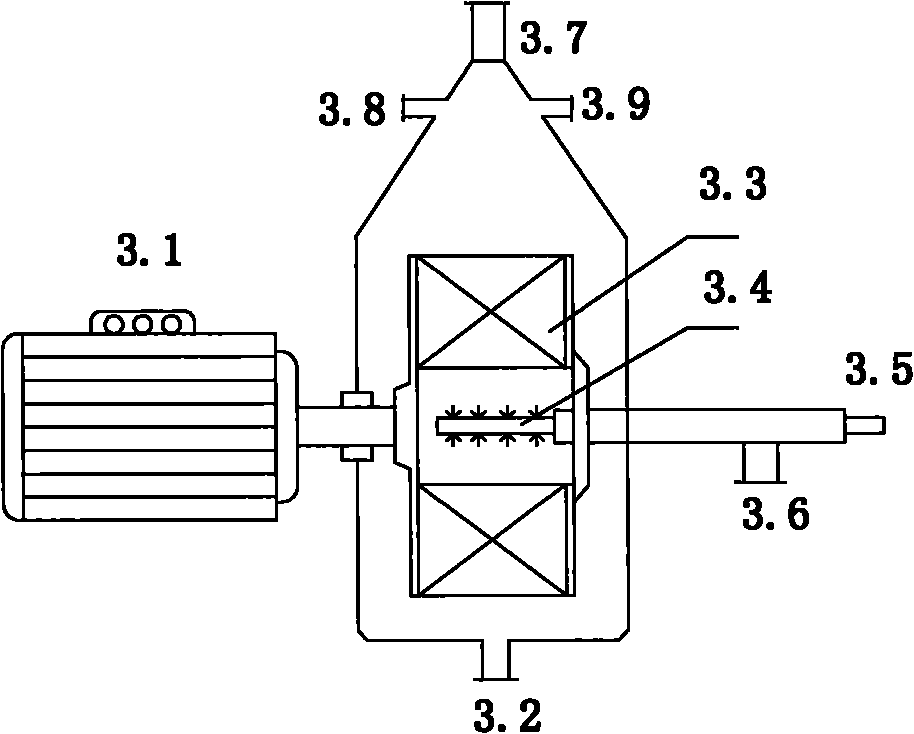

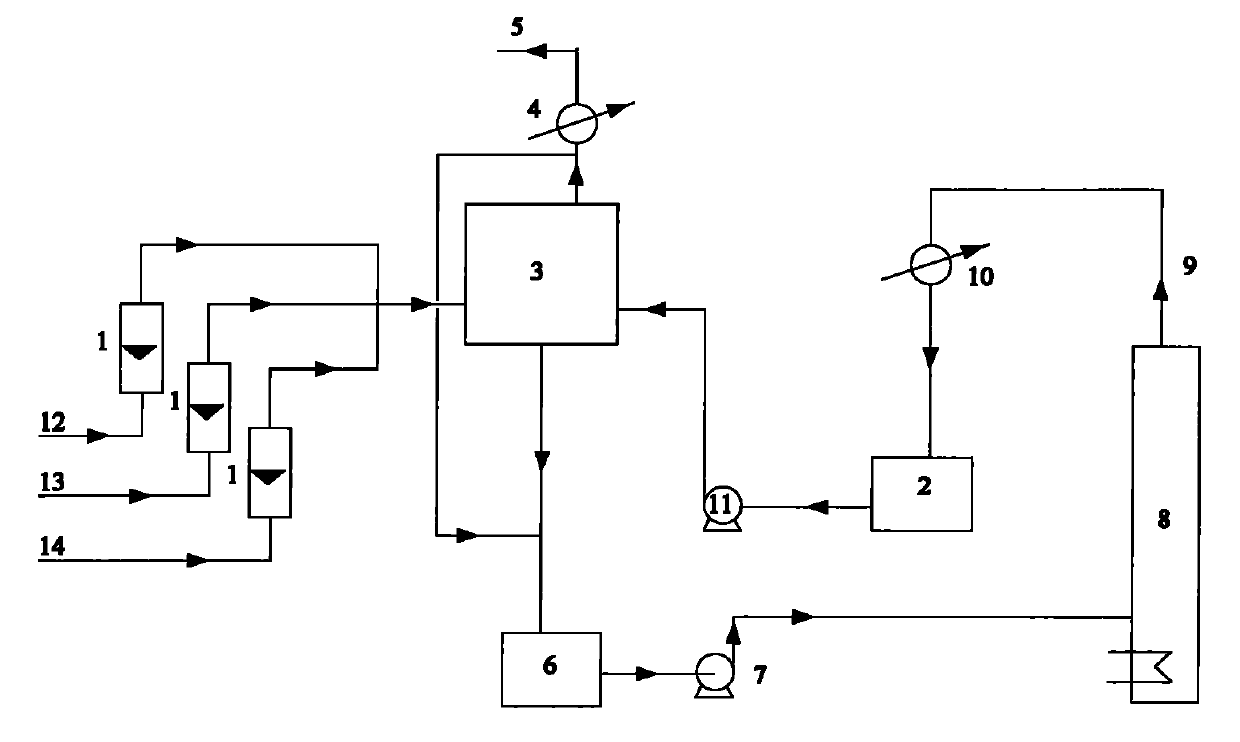

Method used

Image

Examples

Embodiment 1

[0043] Treatment of ethyl nitrite regeneration process in a chemical plant: mixed gas volume of nitric oxide, nitrogen and oxygen is 50000m 3 / h, the molar fraction ratio of each component is 4: 5: 1, the mol ratio that enters ethanol in the rotating packed bed: NO is 1.2, and the rotating speed of rotating packed bed is 200r / min, and filler is stainless steel wire mesh filler, gas-liquid The temperature in the rotating packed bed is 30°C, the temperature of the rectifying tower is 95°C, and the concentration of ethanol after rectification is 94%. The ester selectivity was 99.3%.

Embodiment 2

[0045] Treatment of ethyl nitrite regeneration process in a chemical plant: mixed gas volume of nitric oxide, nitrogen and oxygen is 50000m 3 / h, the molar fraction ratio of each component is 6: 2.5: 1.5, enters the ethanol in the rotating packed bed: the mol ratio of NO is 1.8, and the rotating speed of the rotating packed bed is 2800r / min, and the filler is a plastic mesh filler, gas-liquid The temperature in the rotating packed bed is 40°C, the temperature of the rectifying tower is 85°C, and the ethanol concentration after rectification is 90%. After the gas-liquid reacts in the rotating packed bed, the NO mole fraction of the gas outlet is 0.0010, and the ethyl nitrite The ester selectivity was 99.9%.

Embodiment 3

[0047] Treatment of ethyl nitrite regeneration process in a chemical plant: mixed gas volume of nitric oxide, nitrogen and oxygen is 50000m 3 / h, the molar fraction ratio of each component is 5: 3.76: 1.24, enters the ethanol in the rotating packed bed: the mol ratio of NO is 1.3, and the rotating speed of the rotating packed bed is 1800r / min, and the packing is stainless steel wire mesh packing, gas-liquid The temperature in the rotating packed bed is 35°C, the temperature of the rectifying tower is 90°C, and the ethanol concentration after rectification is 92%. After the gas-liquid reacts in the rotating packed bed, the NO mole fraction at the gas outlet is 0.0003, and the ethyl nitrite The ester selectivity was 99.4%.

[0048] In the foregoing embodiment, the amount of oxygen kept is relatively insufficient, and both NO and ethanol are excessive. Therefore, the selectivity of ethyl nitrite is used as an index, and the yield is expressed as: selectivity of ethyl nitrite=unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com