Method for preparing a fermented soybean meal using bacillus strains

A technology of soybean powder and bacillus, applied in food preparation, application, animal feed, etc., to achieve the effect of improving digestion and absorption speed and reducing total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

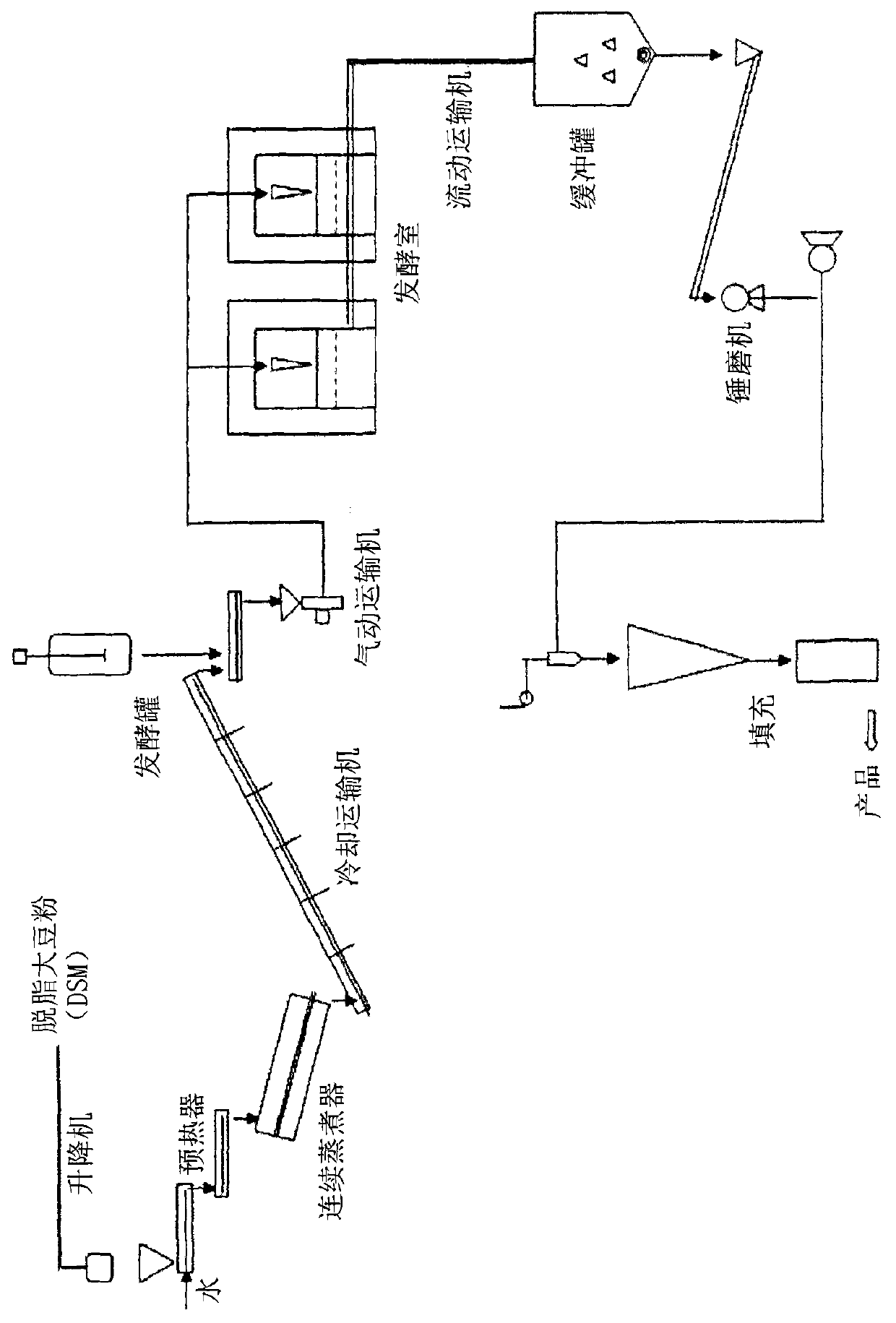

Method used

Image

Examples

Embodiment approach

[0104] Hereinafter, the present invention will be described in more detail with reference to Examples. It will be apparent to those skilled in the art that these examples are for illustrative purposes only and the invention is not intended to be limited in scope.

Embodiment 1

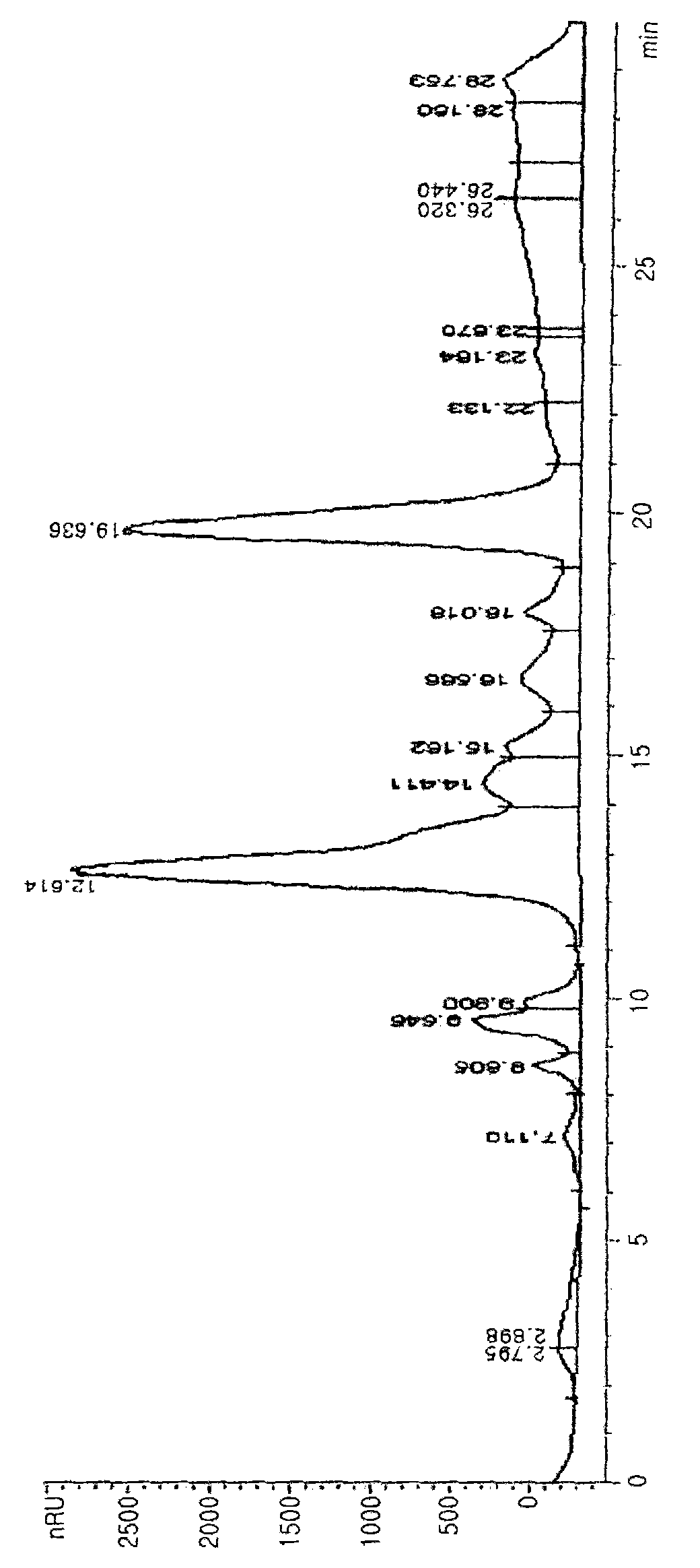

[0107] Example 1: Growth of Bacillus and Lactobacillus according to Moisture Content of Soybean Flour

[0108] In order to determine the moisture content of soybean flour suitable for bacterial culture, water was added to soybean flour at 30%, 40%, 50% and 60% moisture content, and 50 g of the water-added soybean flour was put into a beaker (250 mL). Then, the top of the beaker was covered with aluminum foil and tied tightly with a rubber band. Heat treatment was performed at 80°C for 30 min, followed by cooling.

[0109] According to one embodiment of the present invention, soybean flour fermentation is carried out using preferred Bacillus subtilis TP6 (KFCC 11343P) (hereinafter referred to as "TP6" strain) and Lactobacillus plantarum P23 (KCCM80048) (hereinafter referred to as "P23" strain) . A medium containing xylose 2%, soytone 0.5% and beef extract 0.5% was used for seed culture of TP6 strain, and P23 strain was pre-cultured at 37° C. for 24 hours using MRS broth (Difc...

Embodiment 2

[0117] Embodiment 2: the heat treatment condition of soybean flour

[0118] In the fermentation of soybean flour, heat treatment of water-added soybean flour is important in terms of preventing contamination and providing soybean flour with a chemical environment suitable for fermentation. The present inventors studied the heat treatment conditions of soybean flour. In order to establish minimal heat treatment conditions where contamination can be prevented and inoculated strains can actively grow during fermentation, the moisture content of soybean flour was adjusted to 60%, and then 50 g of it was placed in a 250 mL beaker with the top of the flask Seal with aluminum foil, followed by heat treatment in an autoclave at 60°C, 80°C, 105°C and 121.1°C for 10-30min, respectively.

[0119] In the same manner as in Example 1, 5% of each seed medium of the TP6 and P23 strains was inoculated into each soybean flour heat-treated under different heat treatment conditions, and incuba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com