Automatic test method and instrument for modules of sodium silicate

A water glass modulus and measurement method technology, which is applied in the direction of analyzing the material through chemical reaction and material analysis through observing the influence of the chemical indicator. Long and other problems, to shorten the measurement cycle, improve the accuracy of judgment, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

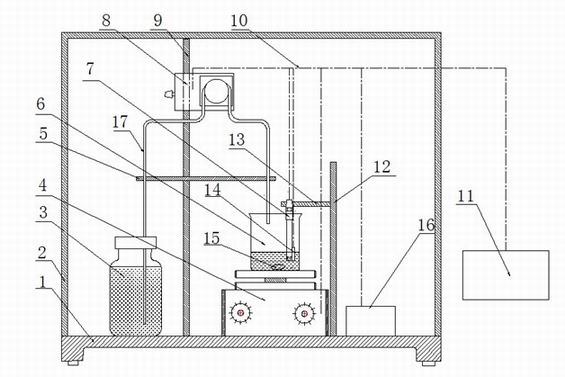

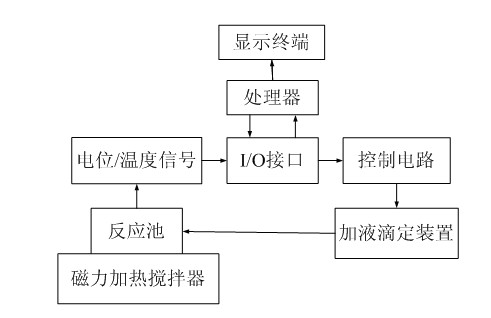

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 The inventive method is measured to known low modulus water glass modulus

[0057] (1) Sample solution preparation: According to the national standard "Industrial Sodium Silicate GB / T 4209-2008", weigh 5g of solid water glass with a known modulus of 1.03, transfer it into a 250mL volumetric flask, add distilled water to the 250mL scale of the volumetric flask , Shake well, this solution is the test solution C, use a pipette to pipette 50mL test solution C and place it in a 150mL beaker.

[0058](2) Titration of sodium oxide: titrate test solution C in the 150mL beaker with the processor to control the precise liquid addition titration device with 0.5mol / L hydrochloric acid standard solution, and record the volume of the used 0.5mol / L hydrochloric acid standard solution for titration with the processor, at the same time Use the pH electrode connected to the processor to monitor the pH value change of the test solution C in real time. When the potential signa...

Embodiment 2

[0063] Embodiment 2 The inventive method is measured to known middle modulus water glass modulus

[0064] Take by weighing 5g known modulus and be the solid water glass of 2.03, concrete steps are with embodiment 1.

[0065] The three titrations of this embodiment are respectively V 1 =8.65mL, V 2 =36.05mL, V 3 =0.75mL, then the modulus of the water glass is m=2.039, consistent with the known water glass modulus m=2.03.

Embodiment 3

[0066] Embodiment 3 The inventive method measures the modulus of high modulus water glass

[0067] Take by weighing 5g known modulus and be the solid water glass of 2.85, concrete steps are with embodiment 1.

[0068] The three titrations of this embodiment are respectively V 1 =5.50mL, V 2 =32.24mL, V 3 =0.87mL, then the modulus of the water glass is m=2.852, consistent with the known water glass modulus m=2.85.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com