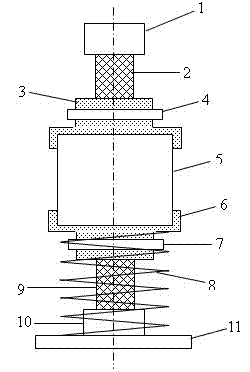

Hydraulic support for direct tensile test device

A tensile test and hydraulic support technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems affecting the accuracy of test data, affecting performance, end damage, etc., to reduce labor Effects of labor intensity, expansion of measurement range, and improvement of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

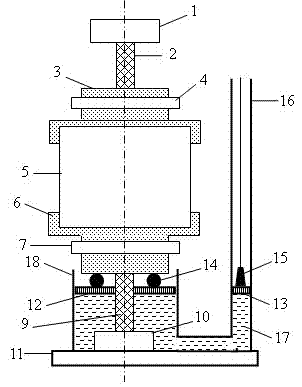

[0036] In the tensile test, use the upper end cap 3 and the lower end cap 6 to fix the sample 5 and tighten it, adjust the liquid level in the hydraulic cylinder (which can be realized by injecting or extracting liquid from the measuring cylinder 16), so that the support pad 14 and the lower end cap 6 contact, and use a weight plate 13 with a higher material density than the support pad 14, or superimpose other weights on the weight plate 13, so that the buoyancy in the hydraulic cylinder is balanced, and the liquid level in the support cylinder 18 and the measurement cylinder 16 are the same. Otherwise, the initial liquid level of the two cylinders is different, which will affect the subsequent test. Above the weighing plate 13, hang the heavy object 15 with a soft rope, so that the heavy object 15 contacts the weighing plate 13, but the weighing plate 13 does not bear the weight of the heavy object 15.

[0037] After installing the device, before the test starts, record the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com