Floating-charge type heat-accumulation power generation device

A power generation device and heat storage technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of large gas storage capacity and large gas tank volume, and achieve high thermal efficiency and stable thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

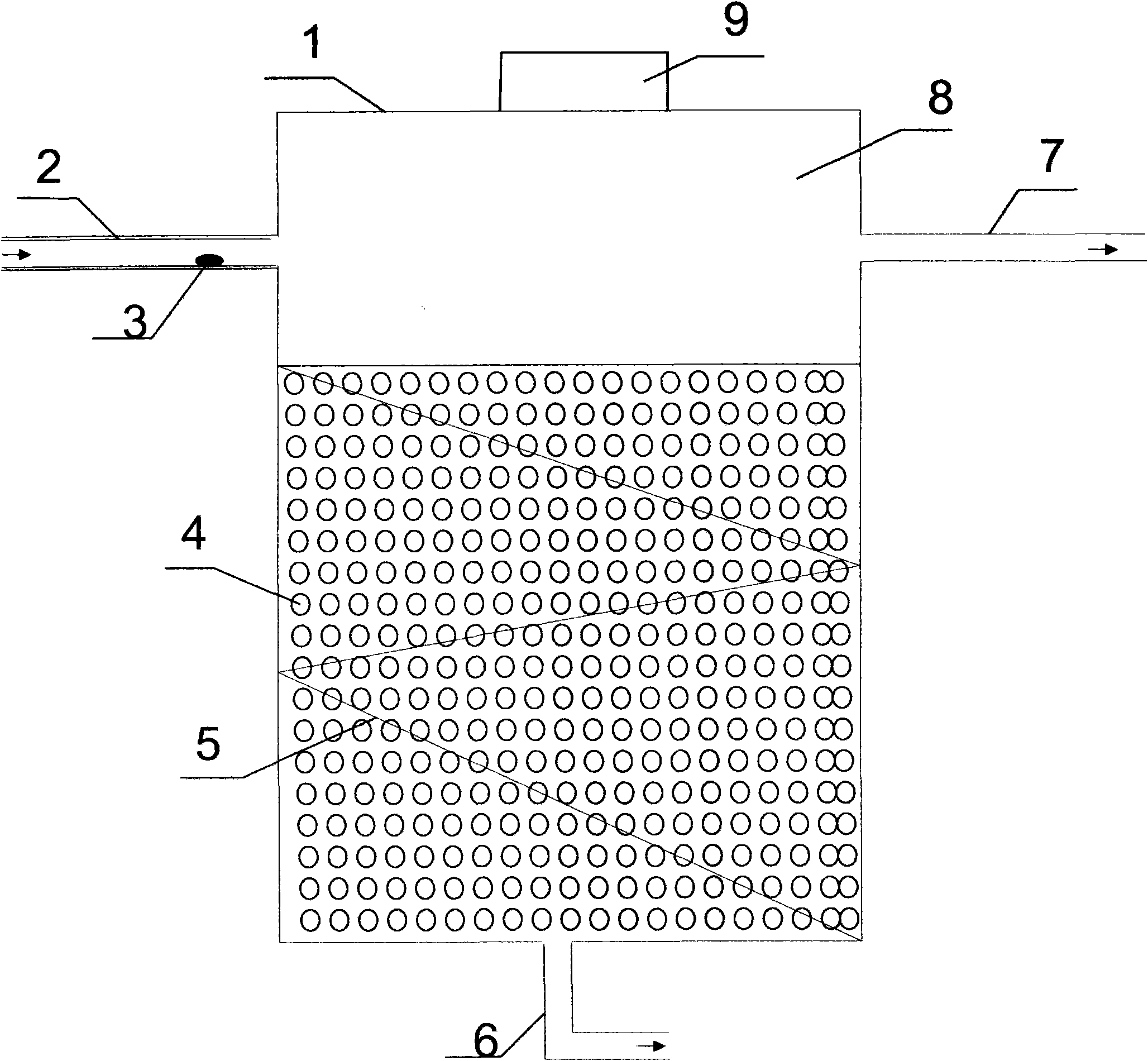

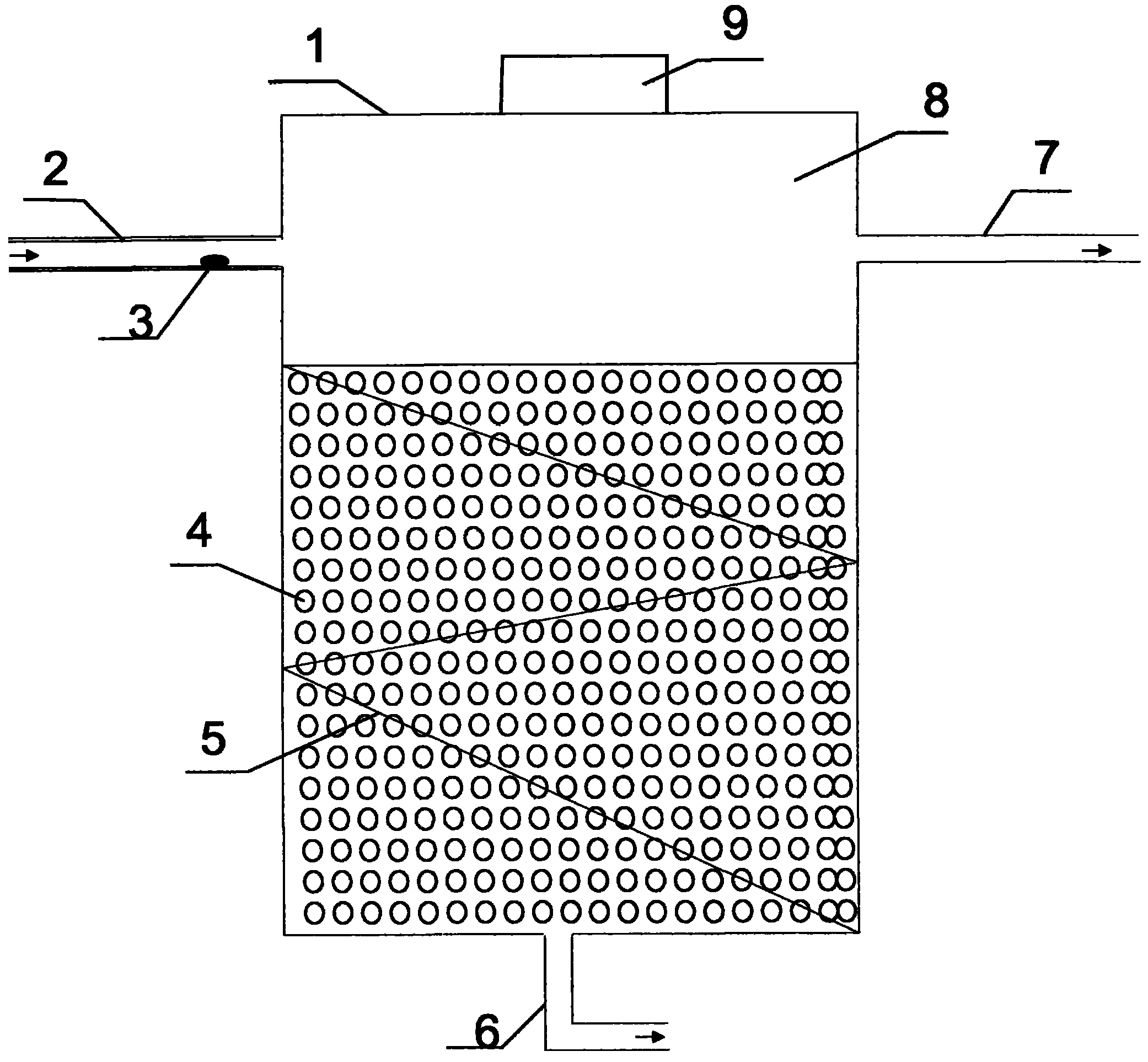

[0022] Fig. 1 shows the overall structure of the present embodiment:

[0023] It consists of a constant temperature heat accumulator and a power generation system 8. The constant temperature heat accumulator is composed of a gas tank 1, a heat storage body 4, an air inlet pipe 2, an air outlet pipe 7 and an exhaust pipe 6. Gas tank 1 has a diameter of 5 meters and a height of 10 meters, and its inner cavity is equipped with multiple heat accumulators 4; the intake pipe 2 that introduces high-temperature exhaust gas is passed into the upper combustion chamber 8 of the gas tank; the gas tank 1 corresponding to the intake pipe 2 On the other side, a gas outlet pipe 7 communicates with the power generation system 8; an exhaust gas pipe 6 protrudes through the bottom of the gas tank. The top of the gas tank 1 is provided with a movable cover 9.

[0024] The folded partition 5 is arranged in the gas tank, and the folded partition 5 is covered with holes, which is beneficial for ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com