Rubber powder modified emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and rubber powder, applied in the direction of climate sustainability, building components, sustainable waste treatment, etc. The effect of good performance, energy reduction and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

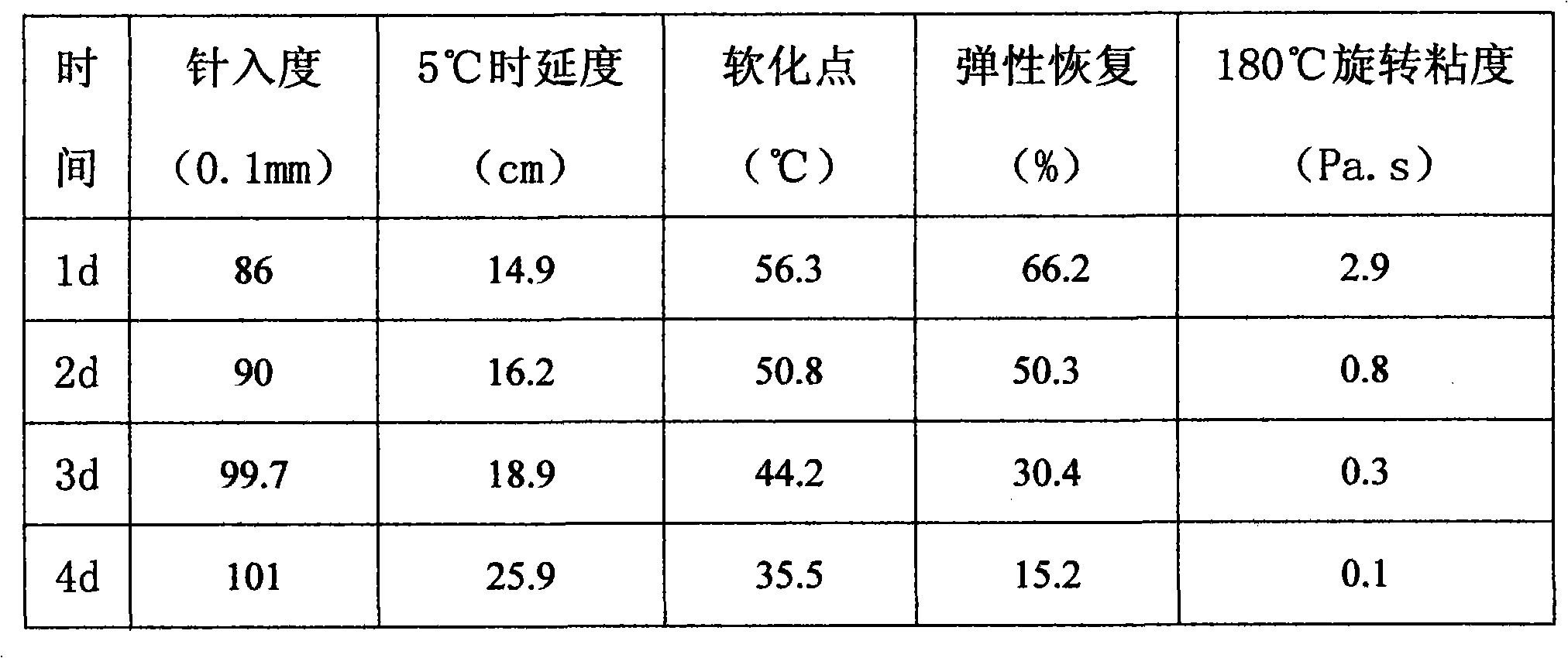

[0026] Take Liaohe No. 90 asphalt 1.5t, use cationic emulsifier, emulsify into associative emulsified asphalt; take water less than 5%, metal content less than 0.4%, ash content less than 8%, mesh number less than 20 mesh waste tire rubber powder 0.3 t, add 0.3% activator of rubber powder mass, stir in the mixing tank at low speed (300-1000 rpm) for 5 minutes, raise the temperature to 150°C, and keep the temperature for 60 minutes to make surface activated rubber powder; add after cooling 50% composite treatment solution of rubber powder quality, the composite treatment solution is composed of 2 parts by mass of SBR emulsion and 5 parts by mass of soap solution, and then stirred at a low speed (300-1000 rpm) for 5 minutes; the rubber powder after composite treatment was added Grind the emulsified asphalt once more with a high-speed shearing machine to obtain rubber powder modified asphalt, the performance index of which is:

[0027] Demulsification speed: medium crack;

[002...

Embodiment 2

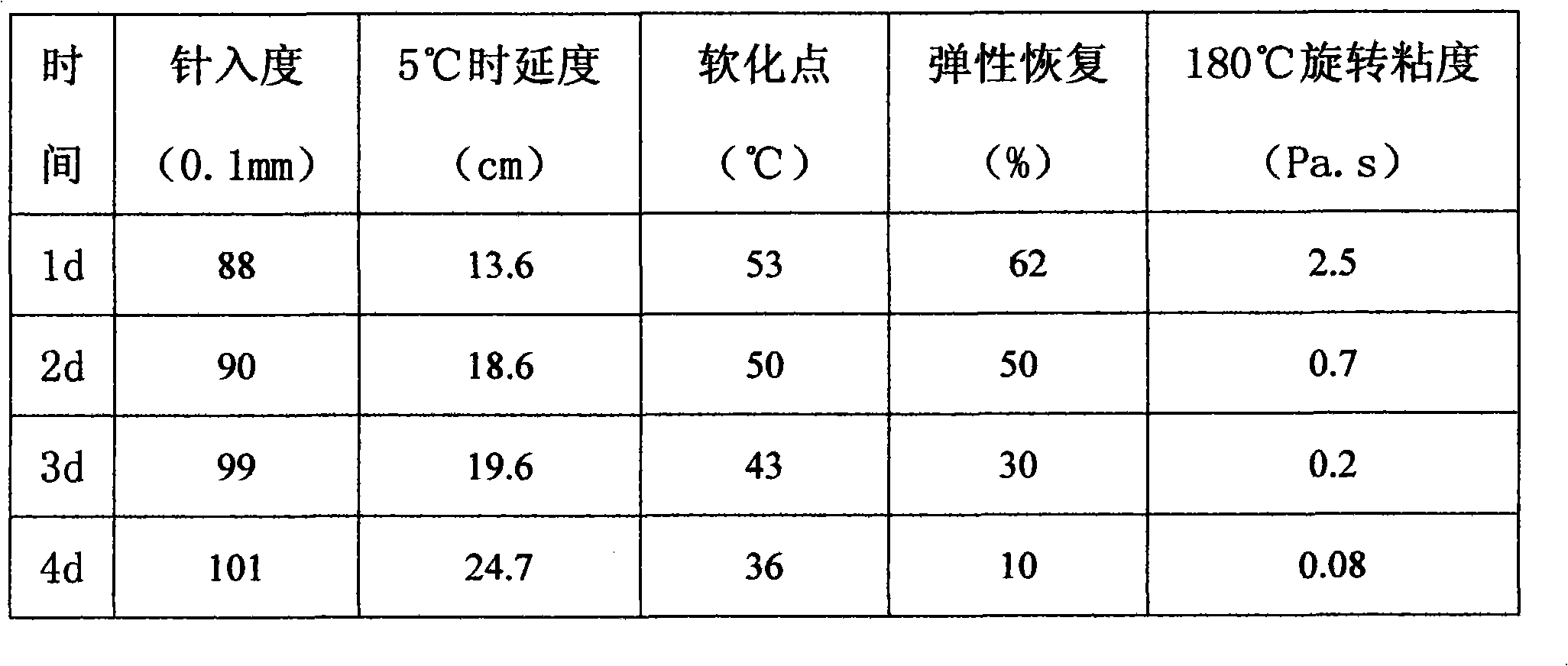

[0038] Take Liaohe No. 90 asphalt 1.5t, use cationic emulsifier, emulsify into associative emulsified asphalt; take water less than 5%, metal content less than 0.4%, ash content less than 8%, mesh number less than 20 mesh waste tire rubber powder 0.15 t, add coupling agent accounting for 1.2% of the mass fraction of the rubber powder, and then add 0.3% of the activator of the rubber powder mass, in the mixing tank, stir at a low speed (300-1000 rpm) for 5 minutes, and heat up to 150 ° C, Keep the temperature for 60 minutes, after cooling, add a composite treatment solution with the same quality as the rubber powder, wherein the composite treatment solution is composed of 2 parts by mass of SBS emulsion, 2 parts by mass of reclaimed rubber solution and 6 parts by mass of soap solution, and then stir at a low speed (300-1000 rpm / min) for 5 minutes; add the compounded rubber powder into the emulsified asphalt, and then grind it twice with a high-speed shearing machine to obtain a...

Embodiment 3

[0050] Take Liaohe No. 90 asphalt 1.5t, use cationic emulsifier, emulsify into associative emulsified asphalt; take water less than 5%, metal content less than 0.4%, ash content less than 8%, mesh number less than 20 mesh waste tire rubber powder 0.2 t, add coupling agent accounting for 1.2% of the mass fraction of the rubber powder, and then add 0.3% of the activator of the rubber powder mass, in the mixing tank, stir at a low speed (300-1000 rpm) for 5 minutes, and heat up to 150 ° C, Hold the temperature for 60 minutes, add 60% composite treatment solution of rubber powder mass after cooling, the composite treatment solution is composed of 2 parts by mass of SBR emulsion, 2 parts by mass of SBS emulsion and 6 parts by mass of soap liquid, and then stir at a low speed (300~1000 rpm ) for 5 minutes; add the compounded rubber powder into the emulsified asphalt, and then grind it 3 times with a high-speed shearing machine to obtain the rubber powder modified asphalt. The perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com