Automatic reducing device of seam welder

A rolling welding machine, automatic technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of reducing waste, reducing straightening and cutting "processes, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

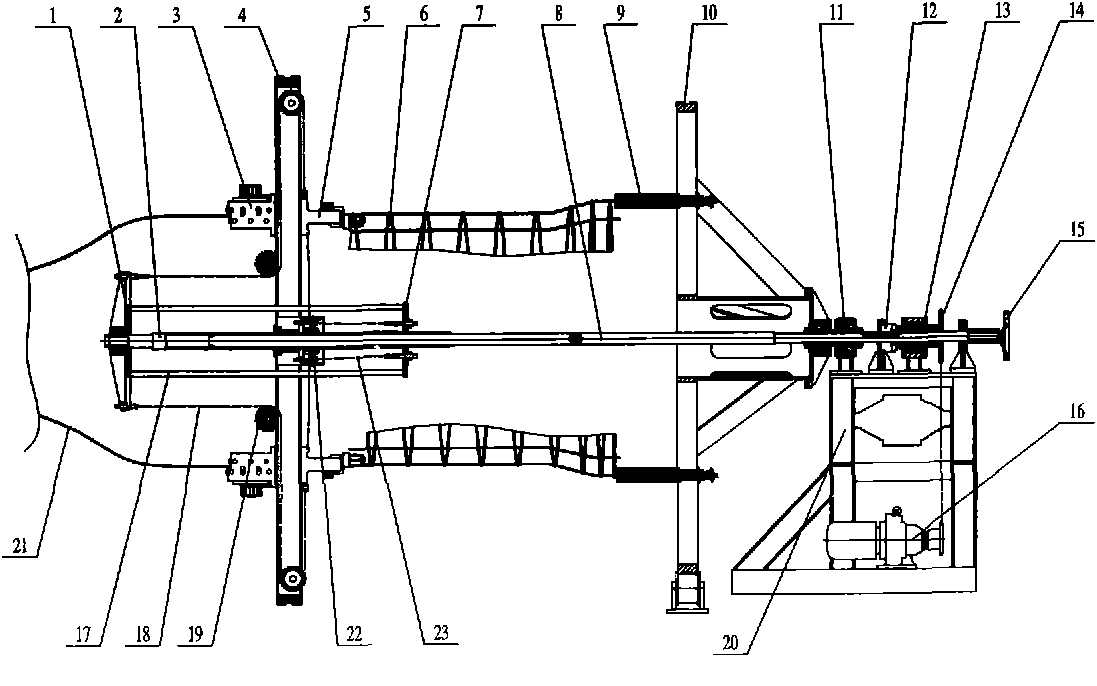

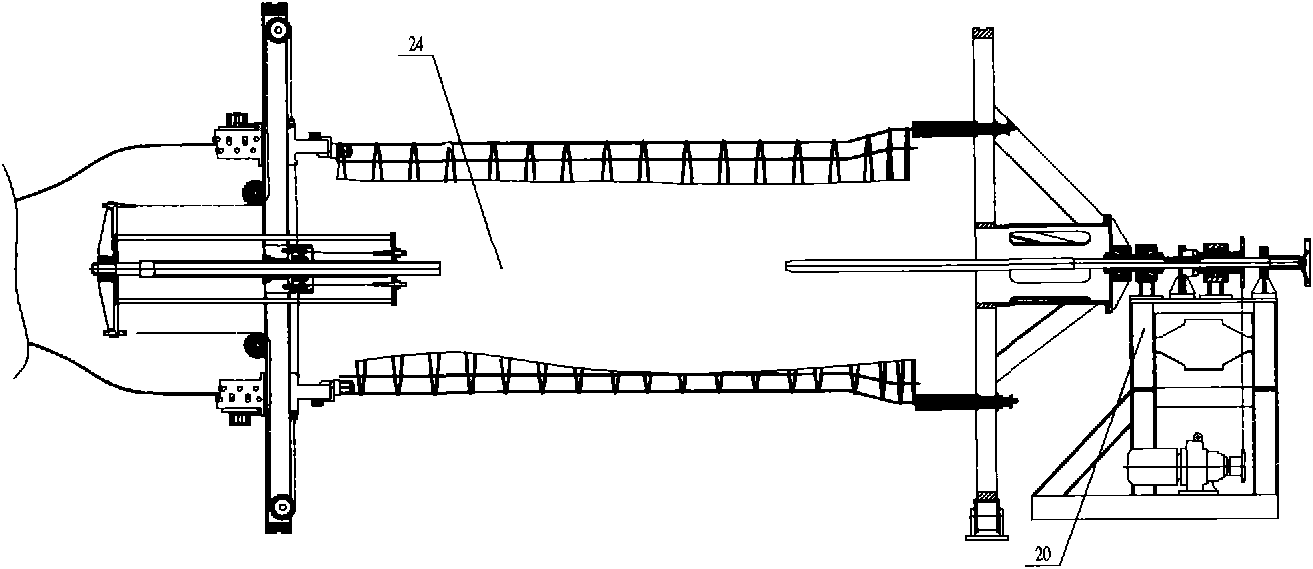

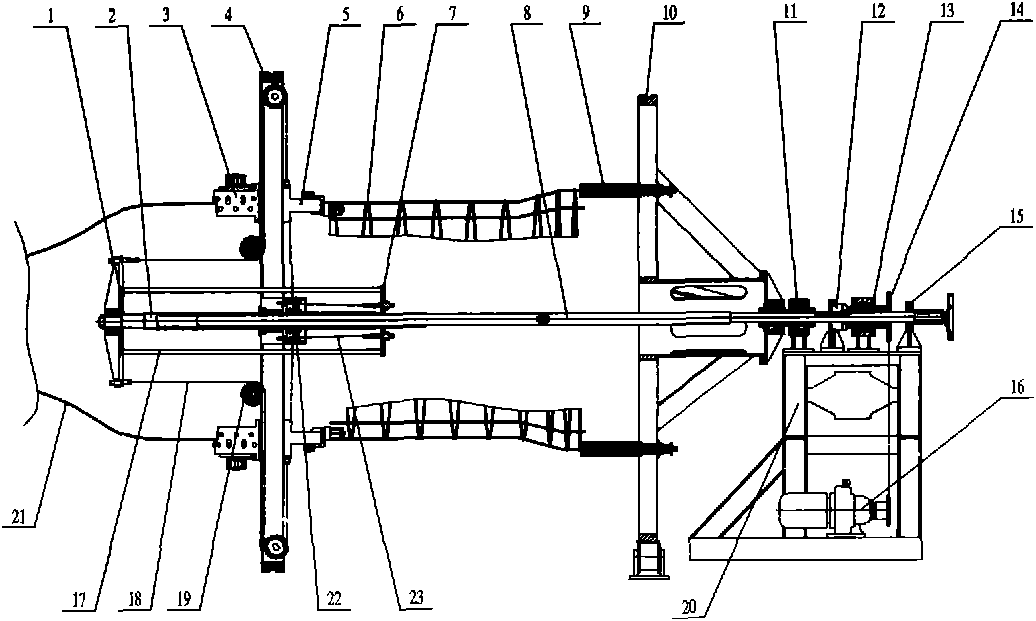

[0015] The present invention as figure 1 , 2 As shown, it includes a frame, a main disc 4, a welding head 5, a tensioning disc 10 coaxial with the main disc 4 and a tendon trolley 20 that drives the tensioning disc 10 to move axially. a radial chute, the welding head 5 is connected to the main disc 4 through the radial chute,

[0016] The automatic diameter-reducing device includes a diameter-reducing cylinder arranged on the main plate 4 to drive the radial movement of the welding head 5; a diameter-reducing cylinder control mechanism arranged on the tendon trolley 20 to control the axial movement of the diameter-reducing cylinder; The center of the main disc 4 is provided with a threaded hole;

[0017] Described reducing cylinder comprises reducing screw mandrel 2, rear disc 1, front disc 7, chain one 18, reversing wheel group one 19, chain two 23, reversing wheel group two 22 and connecting rod 17; The screw rod 2 is connected to the threaded hole in the center of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com