Socket sleeve for transformer

A technology of transformers and sockets, applied in the direction of cable terminals, etc., can solve problems such as unsightly appearance, reduced volume, cracking of solid insulating materials, etc., and achieve the effects of stable and reliable operation, convenient installation and use, and excellent protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

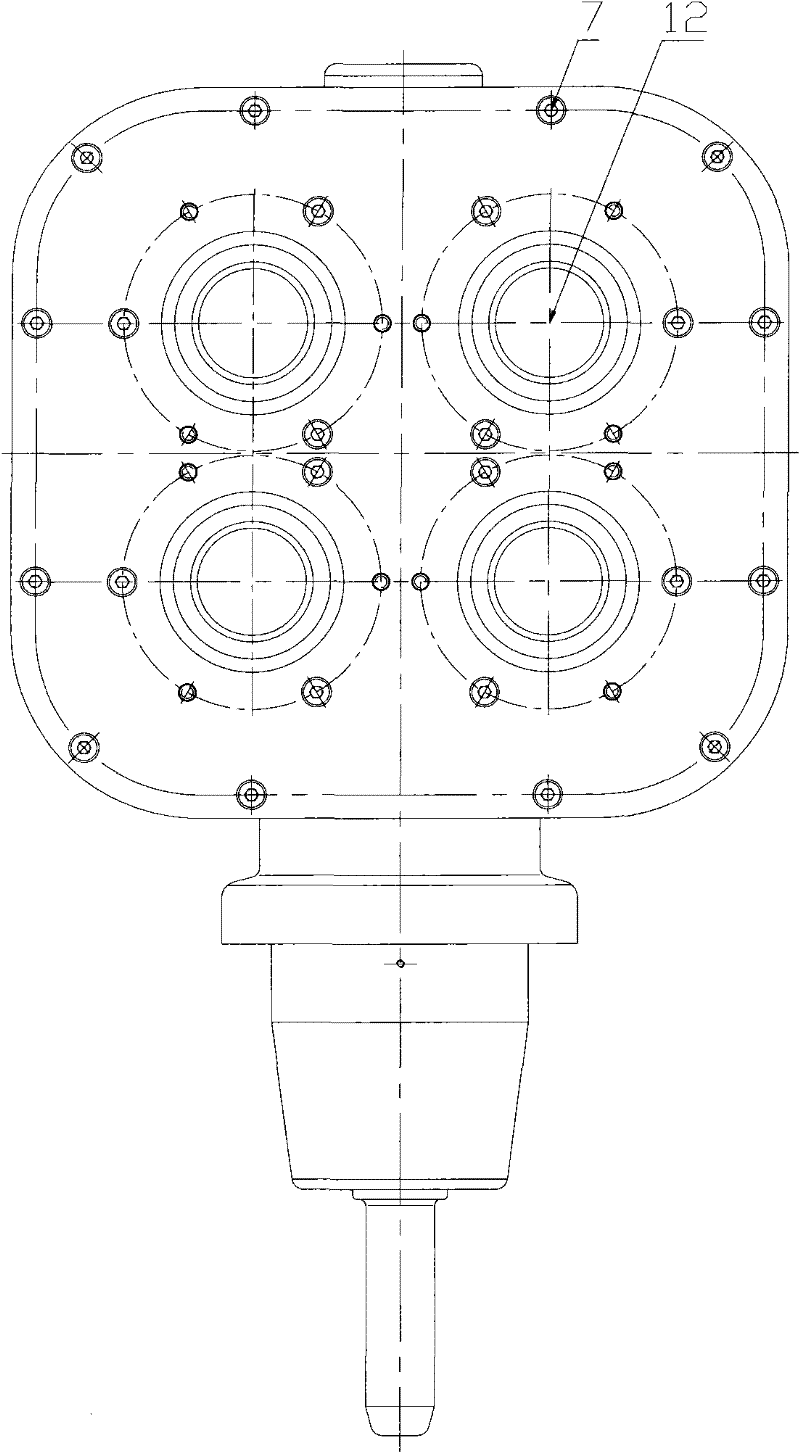

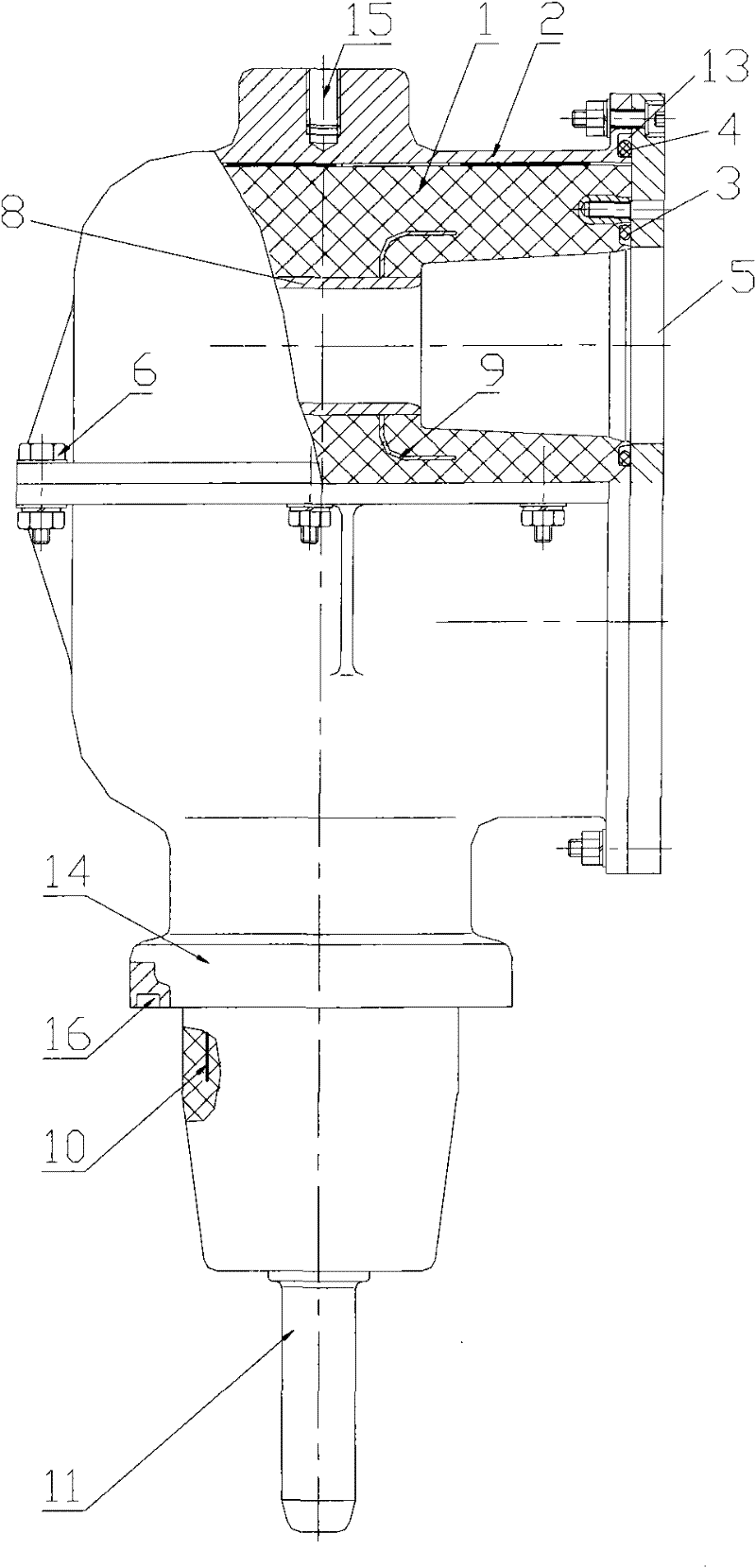

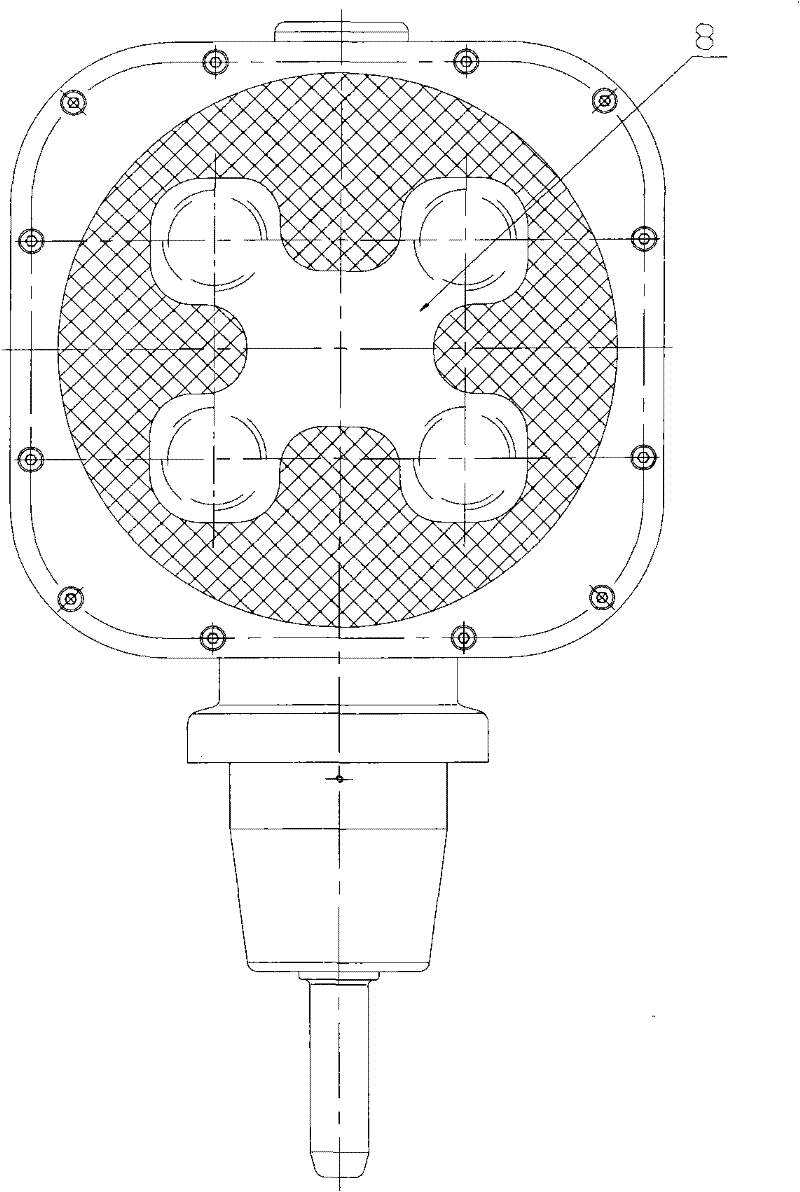

[0027] Transformer socket bushing structure of the present invention is as follows Figure 1a , Figure 1b and figure 2 As shown, a solid insulating layer 1 formed of epoxy insulating material, a rectangular or square metal shell 2 with arc-shaped corners (the metal shell 2 can be divided into two parts and fixed by screws 6 or integrally formed) and the metal shell The body 2 is composed of a metal cover plate 5 that is fixed on the opening end surface of the metal shell by a hexagon socket head cap screw 7 . After the solid insulating layer 1 is formed by casting, it is filled and fixed in the metal shell 2 . The side of the solid insulating layer 1 facing the opening of the metal shell 2 is provided with four independent cable terminal socket holes 12 distributed on the "X"-shaped end points, and the four cable terminal socket holes 12 are symmetrical with respect to the center line of the metal shell The structure of the cable terminal socket hole 12 matches the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com