High-sensitivity uncooled infrared detector

An uncooled infrared and detector technology, applied in the field of infrared detectors, can solve the problems of increased cost, complex process, thermal isolation of detectors and unreasonable infrared absorption layer structure design, etc., and achieves good stability, reliability, cost and so on. The effect of low and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

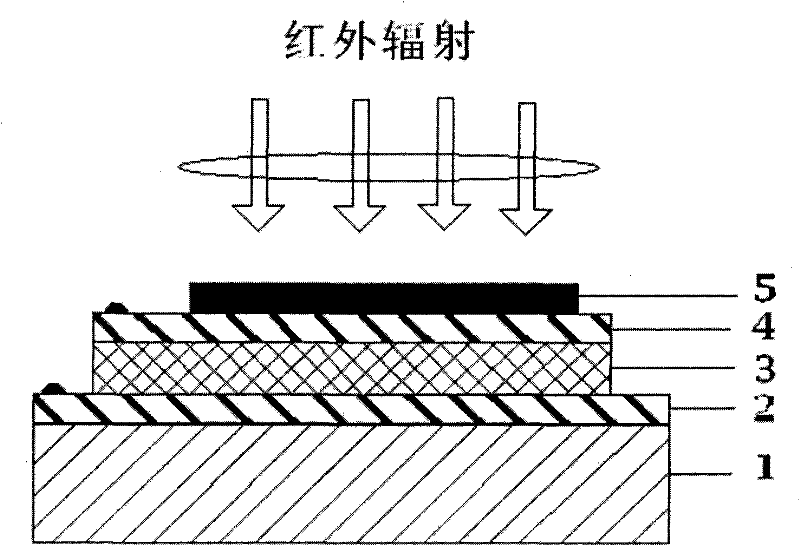

[0029] The following will be combined figure 1 , to express the specific implementation method of the present invention:

[0030] (1) A polyester film with a thickness of 2.5 microns is selected as the substrate (see figure 1 Medium 1).

[0031] (2) Bottom electrode preparation, evaporate one deck metal aluminum film on substrate film as bottom electrode, and electrode is bar shape, and width is 0.5 millimeter, and thickness 70 nanometers, (see figure 1 Medium 2).

[0032] (3) P(VDF-TrFE) thin film preparation, the P(VDF-TrFE) thin film material is grown on the polyester film substrate with the bottom electrode prepared using the Langmuir-Blodgett (LB) technique. Specifically, weigh 0.02 g of P(VDF-TrFE, 70:30mol%), transfer to a 250 ml flask, add 100 ml of dimethyl sulfoxide (DMSO), stir at 80°C for 3 hours, and cool to room temperature . The LB thin film growth system is used to grow P(VDF-TrFE) polymer film. The single-layer film is pulled under the surface pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com