Efficient full-wet inner surface evaporator

A technology for evaporators and inner surfaces, applied in evaporators/condensers, compressors, refrigeration components, etc., can solve problems such as poor oil return effect of compressors, cylinder flushing accidents, hysteresis and periodic oscillation instability, etc. Achieve the effects of ensuring normal and safe operation, avoiding segmented flow, and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

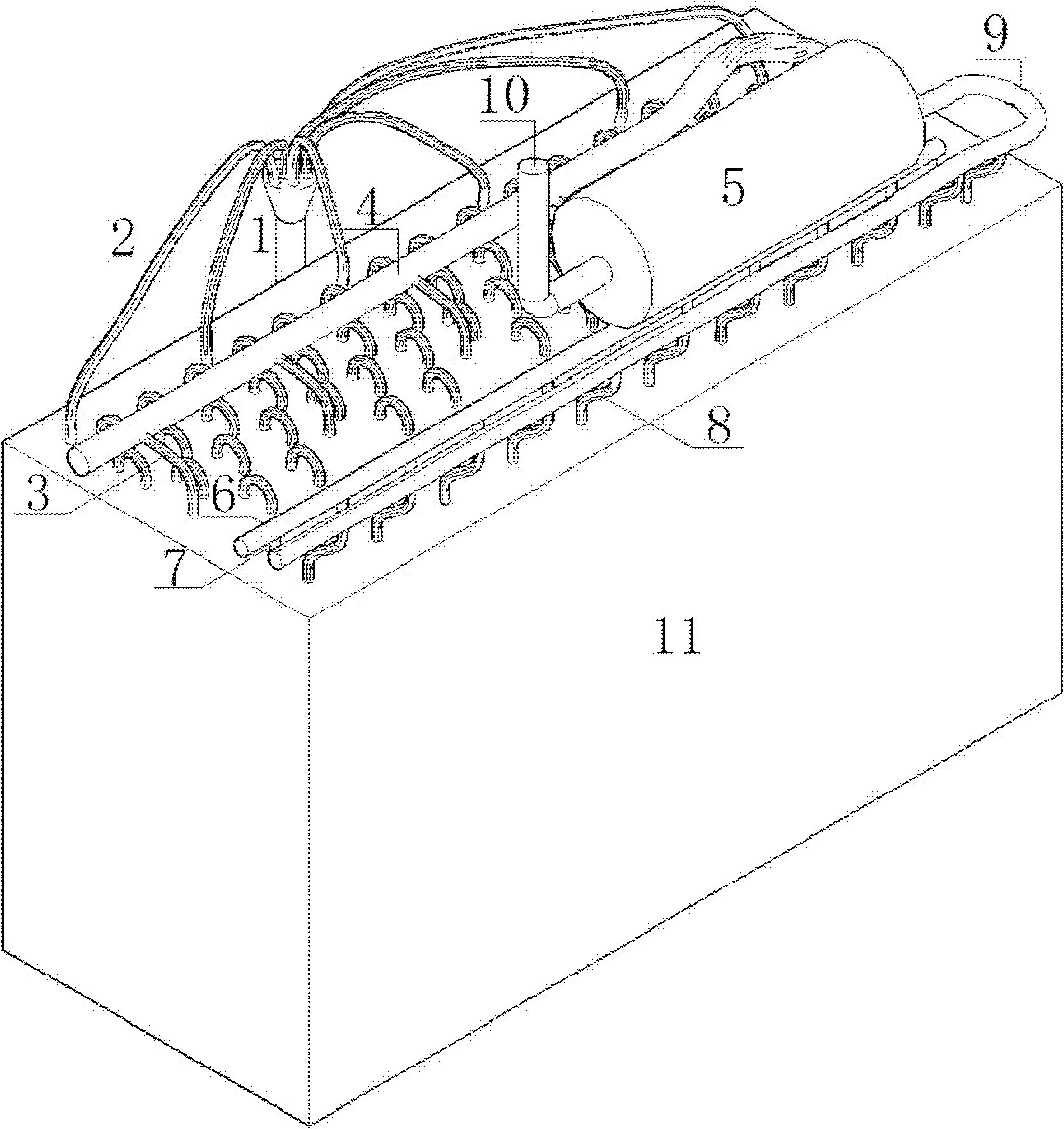

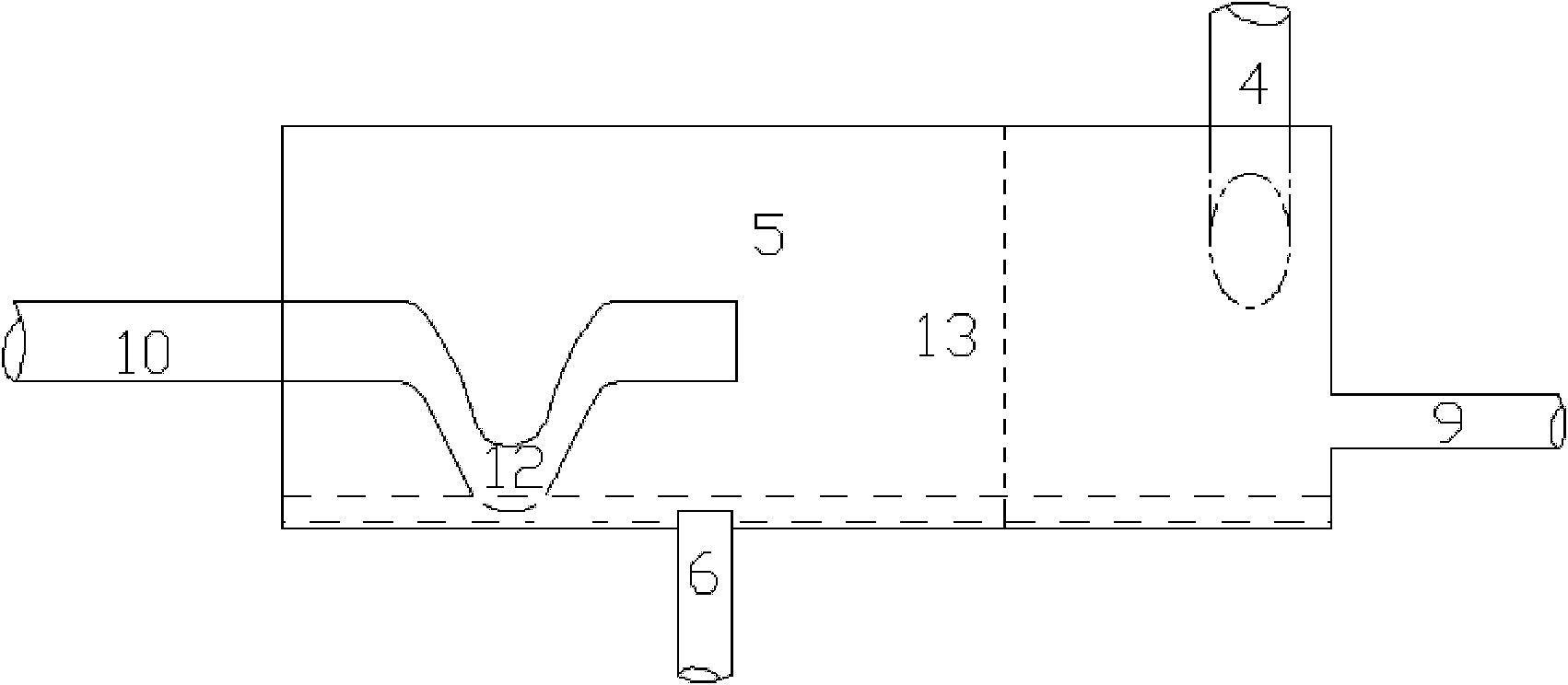

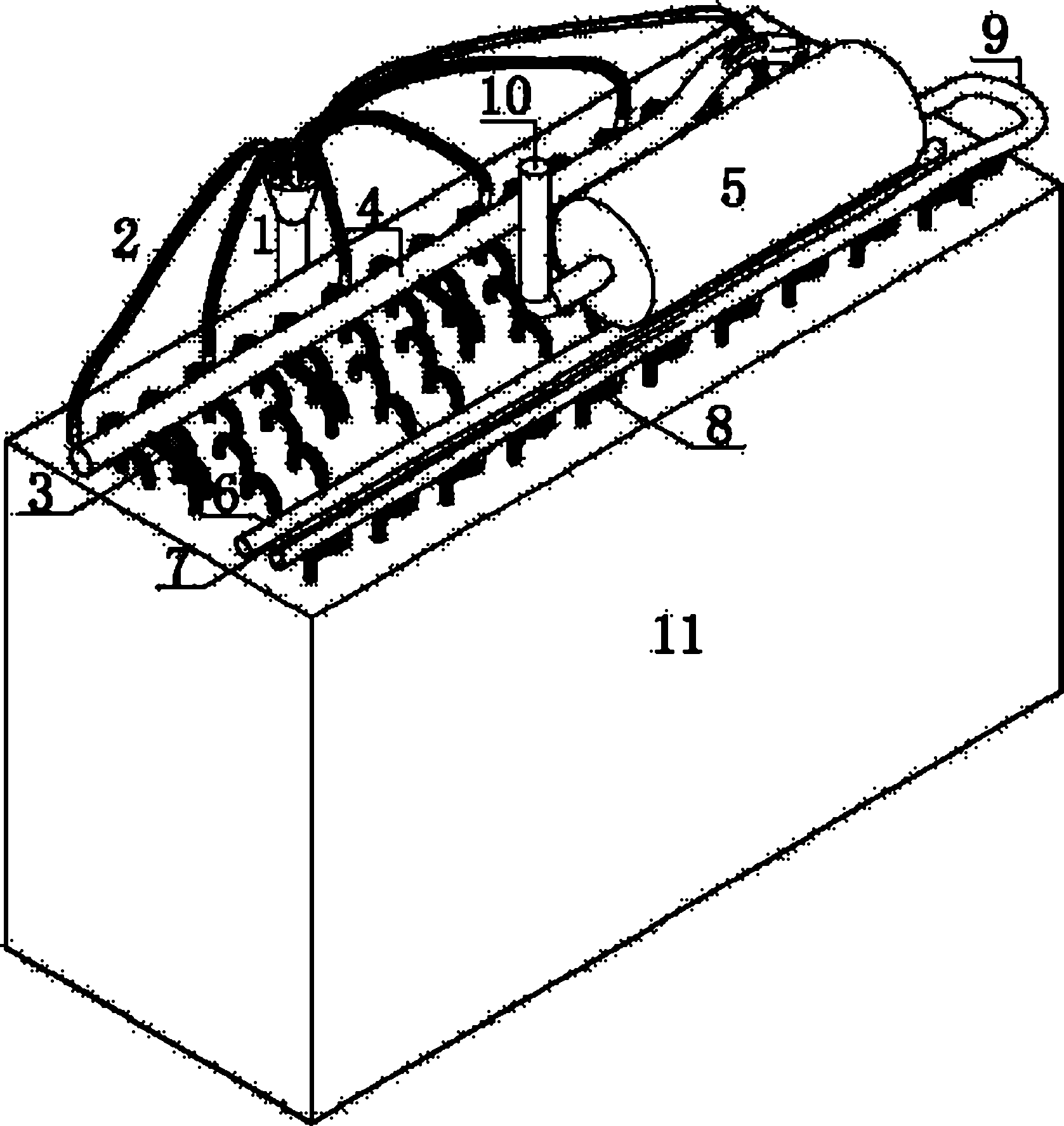

[0012] A high-efficiency full-humidity internal surface evaporator, mainly composed of a refrigerant distributor 1, a primary evaporation heat exchange tube 2, a refrigerant primary return pipe 3, a refrigerant primary return main pipe 4, a gas-liquid separator (5) and a refrigerant The air return pipe 10 is connected in sequence, and the bottom of the gas-liquid separator 5 is connected to the secondary evaporation air intake main pipe 6, the secondary evaporation heat exchange pipe 7, the refrigerant secondary return air pipe 8 and the secondary evaporation return air main pipe 9 , and finally return to the gas-liquid separator 5; the primary evaporation heat exchange tube 2 and the secondary evaporation heat exchange tube 7 are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com