Turbine exhaust gas temperature calculation and difference degree protection method

A technology of exhaust gas temperature and calculation method, applied in the direction of calculation, computer-aided design, instruments, etc., can solve the problems of cracking, not being overcome, uneven exhaust gas temperature distribution, etc. The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

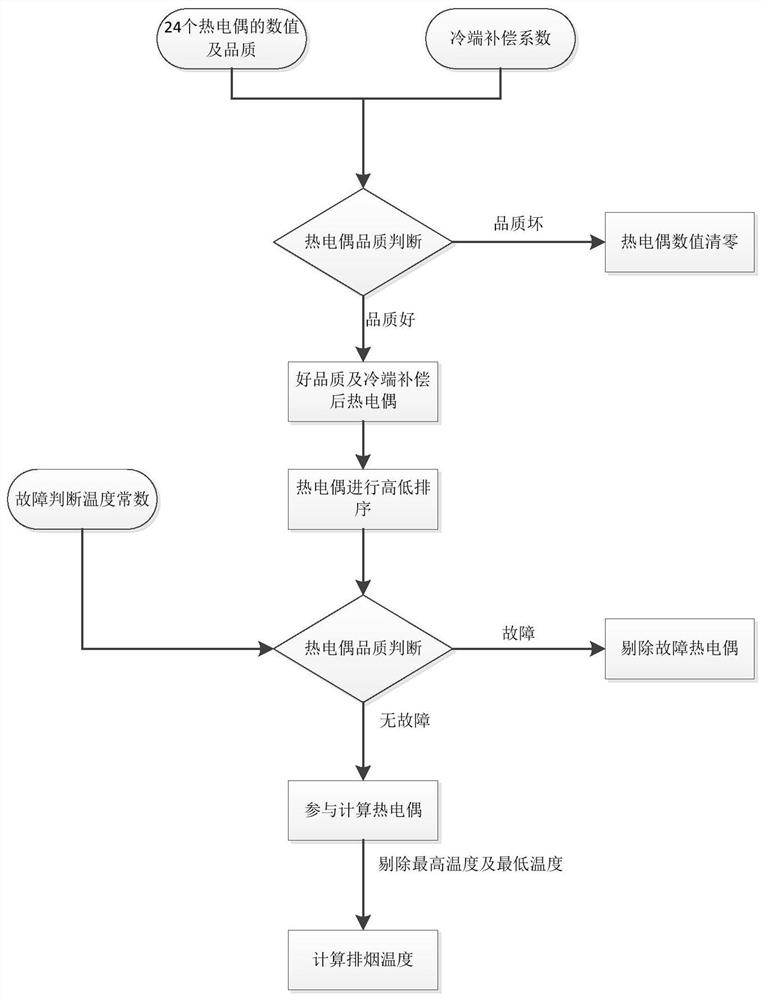

[0050] Such as figure 1 As shown, a calculation method of turbine exhaust gas temperature includes:

[0051] 24 thermocouples are evenly arranged in 24 different parts of the smoke exhaust area of the gas turbine;

[0052] Cold junction compensation for real-time thermocouple data;

[0053] Carry out quality judgment on the real-time thermocouple data, eliminate the thermocouple whose quality is bad, and set its data to zero;

[0054] Sort the thermocouple data after cold junction compensation;

[0055] Perform fault judgment on the thermocouple data after high-low sorting, and eliminate the faulty thermocouple;

[0056] Output the thermocouple temperature after excluding the faulty therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com