Method for improving crystallization property of PTT or PTT/PBT blend

A mixture and premixing technology, which is applied in the field of polymer processing, can solve the problems of inapplicability, achieve the effect of increasing the crystallization rate and crystallization temperature, fine and uniform crystal morphology, and improving processing performance and molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

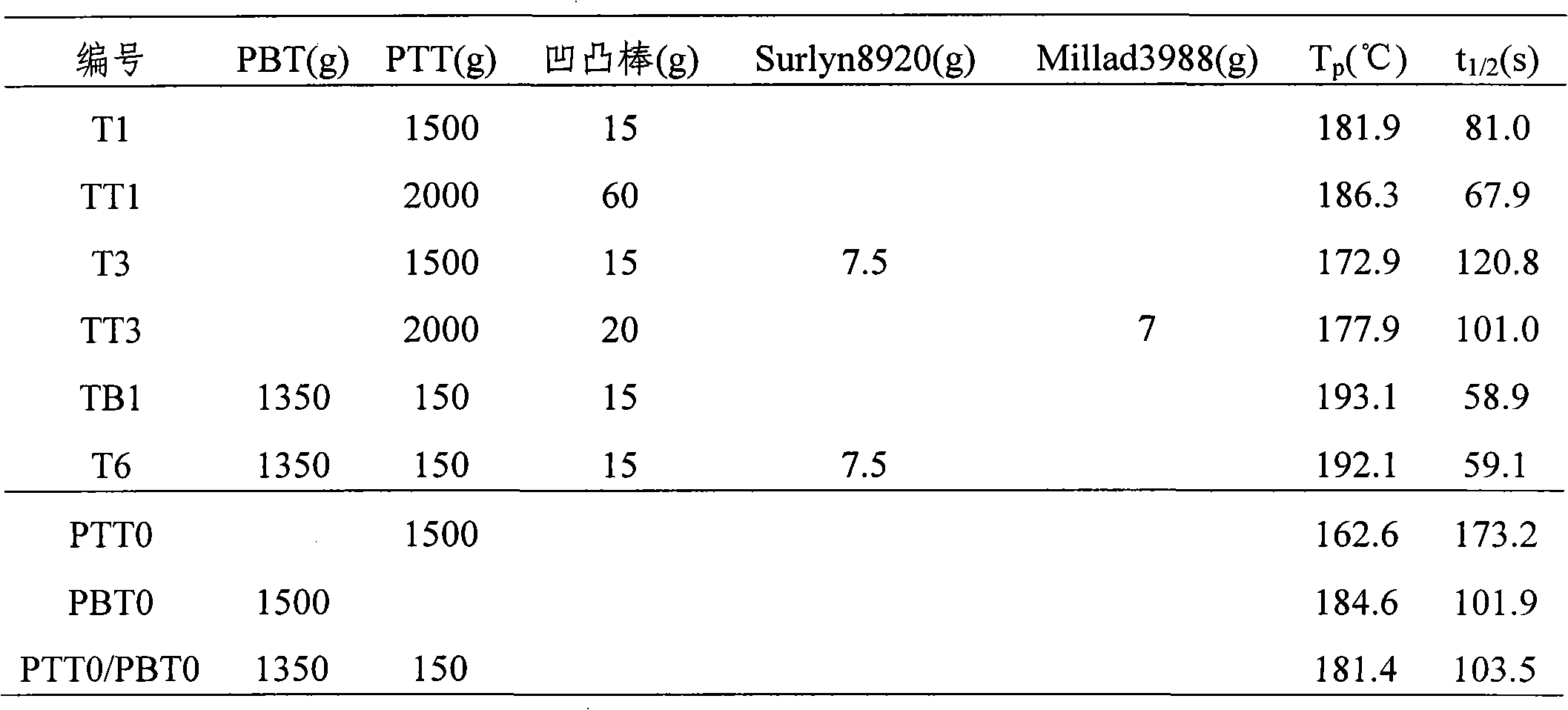

[0044] (1) Premixing: Add 1500g of PTT with an intrinsic viscosity of 0.9dl / g and 15g of attapulgite with an average particle diameter of 0.5 to 1.0μm in the length direction and 0.1 to 0.15μm in the width direction into the high-speed mixer in sequence. Mix for 5 minutes at a temperature of 30°C and a rotation speed of 200 rpm to form a mixture;

[0045] (2) Extrusion granulation: Add the material mixed in step (1) into the co-rotating parallel twin-screw extruder, control the extrusion temperature of each section to 220-250°C, the screw speed is 450rpm, and the feeder speed is 50rpm, obtains the PTT complex product, and its product performance is shown in T1 item in Table 1.

Embodiment 2

[0047] (1) Premixing: 2000g of PTT with an intrinsic viscosity of 1.05dl / g and 60g of attapulgite with an average particle diameter of 0.5 to 1.0μm in the length direction and 0.1 to 0.15μm in the width direction are added to the high-speed mixer in sequence. Mix for 3 minutes at a temperature of 25°C and a rotation speed of 100 rpm to form a mixture;

[0048] (2) Extrusion granulation: Add the material mixed in step (1) into the co-rotating parallel twin-screw extruder, control the extrusion temperature of each section to 220-250°C, the screw speed is 300rpm, and the feeder speed is 30rpm, obtain the PTT compound product, its product performance sees TT1 item in Table 1.

Embodiment 3

[0050] (1) Premixing: Add 1500g of PTT with an intrinsic viscosity of 1.3dl / g, 15g of attapulgite with an average particle size of 0.5-1.0μm in the length direction and 0.1-0.15μm in the width direction, and 7.5g of Surlyn8920 in sequence A high-speed mixer, mixing at a temperature of 25°C and a rotation speed of 200rpm for 4 minutes to form a mixture;

[0051] (2) Extrusion granulation: Add the material mixed in step (1) into the co-rotating parallel twin-screw extruder, control the extrusion temperature of each section to 220-250°C, the screw speed is 400rpm, and the feeder speed is 40rpm, obtain the PTT compound product, and its product performance is shown in T3 item in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com