Method for preparing special silica gel carrier with large pore volume and large specific surface area

A technology with large specific surface area and large pore volume, applied in the field of preparation of special silica gel carrier for high-activity gas-phase ethylene polymerization catalyst, to prevent the shrinkage of pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

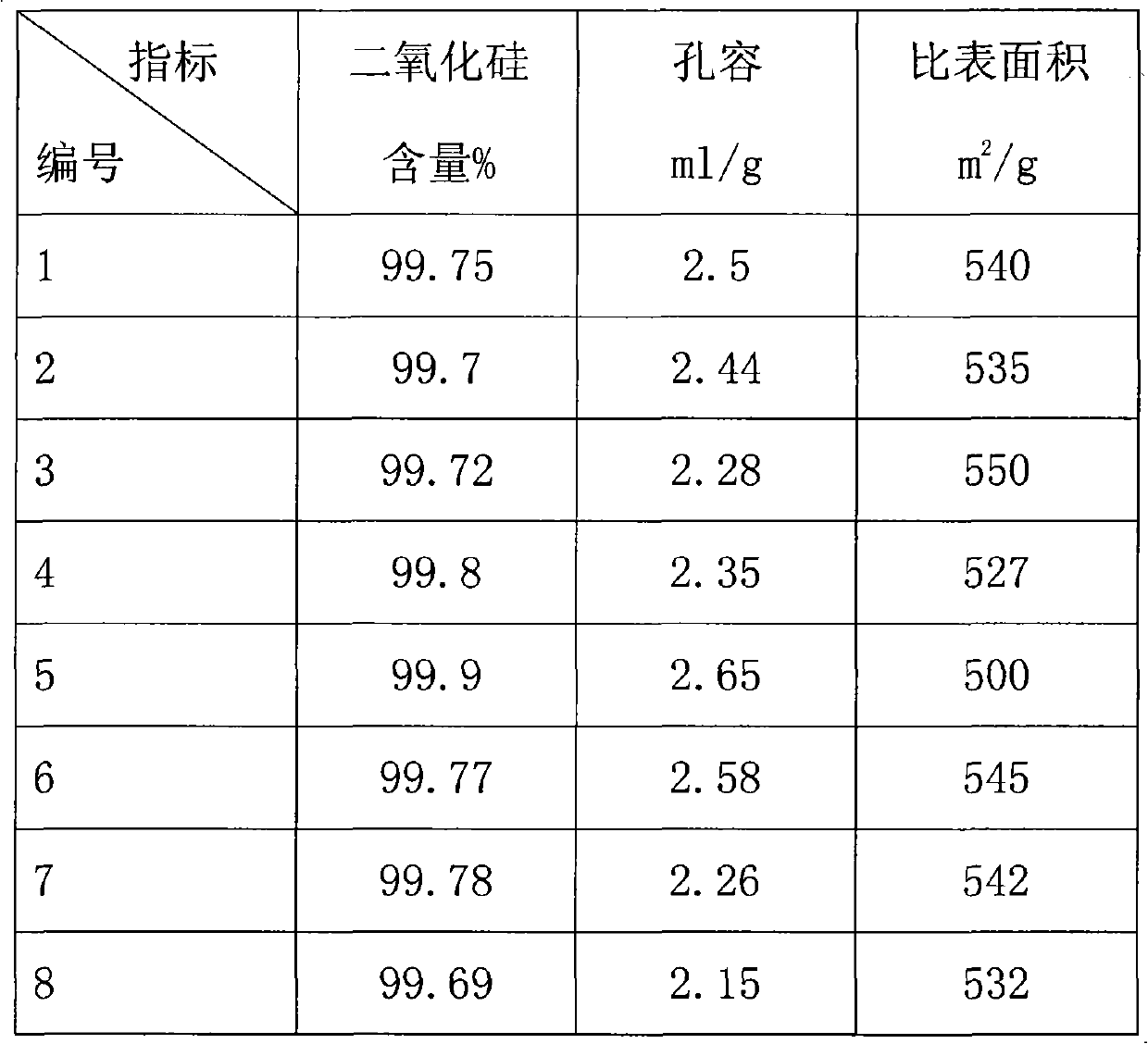

Embodiment 1

[0020] 1. Dilute industrial sodium silicate with a modulus of 3.1 to a concentration of 10% industrial sodium silicate solution with a mass content of silicon dioxide; add dropwise a sulfuric acid solution with a mass content of 25% at an initial temperature of 20°C to adjust System pH to 2-4, keep the final adjusted pH value at 3.5-4;

[0021] 2. Raise the temperature to the final temperature of 95-100°C, add the specific surface control agent glycerin, and the addition amount of the specific surface control agent is 1% of the mass content of sodium silicate;

[0022] 3. Insulate at the final temperature for 2 hours to carry out hydrothermal reaction; then age at room temperature for 2 hours; wash with water until the mass content of sodium ions is below 0.05%; dry by spray drying: keep the temperature at 400°C; Then carry out particle size classification, the average particle size is 75-150 microns, to obtain the final product of macroporous microsphere silica gel with water...

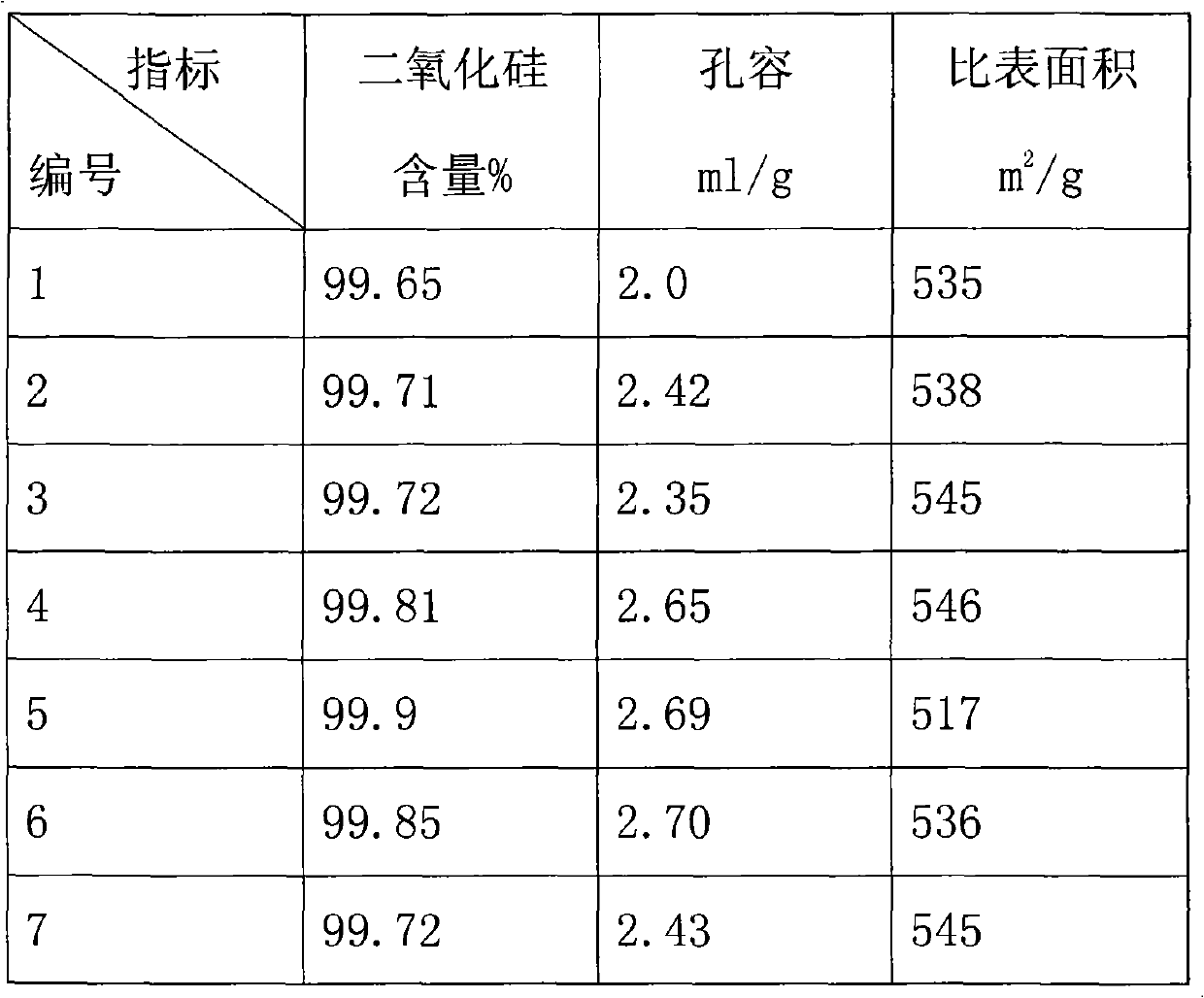

Embodiment 2

[0027] 1. Dilute industrial sodium silicate with a modulus of 3.2 to a concentration of 15% industrial sodium silicate solution with a mass content of silicon dioxide; add dropwise a sulfuric acid solution with a mass content of 20% at an initial temperature of 30°C to adjust System pH to 2-4, keep the final adjusted pH value at 3.5-4;

[0028] 2. Raise the temperature to the final temperature of 80-85°C, add the specific surface control agent ethyl acetate, and the addition amount of the specific surface control agent is 3% of the mass content of sodium silicate;

[0029] 3. Insulate at the final temperature for 3 hours to carry out hydrothermal reaction; then age at room temperature for 1 hour; wash with water until the mass content of sodium ions is below 0.05%; dry by spray drying: keep the temperature at 500°C; Then carry out particle size classification, the average particle size is 75-150 microns, to obtain the final product of macroporous microsphere silica gel with wa...

Embodiment 3

[0034] 1. Dilute the industrial sodium silicate with a modulus of 3.3 to a concentration of 20% industrial sodium silicate solution with a mass content of silicon dioxide; add dropwise a sulfuric acid solution with a mass content of 18% at an initial temperature of 40°C to adjust System pH to 2-4, keep the final adjusted pH value at 3.5-4;

[0035] 2. Raise the temperature to the final temperature of 90-95°C, add the specific surface control agent ethylene glycol, and the addition amount of the specific surface control agent is 3% of the mass content of sodium silicate;

[0036] 3. Insulate at the final temperature for 2 hours to perform hydrothermal reaction; then age at room temperature for 2 hours; wash with water until the mass content of sodium ions is below 0.05%; dry by spray drying: keep the temperature at 600°C; Then carry out particle size classification, the average particle size is 75-150 microns, to obtain the final product of macroporous microsphere silica gel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com