Anaerobic microporous aerator oxidation ditch reactor and sewage treatment method

A microporous aeration and reactor technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high investment and high operating costs, and save land. area, reduced processing costs, enhanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawings and examples.

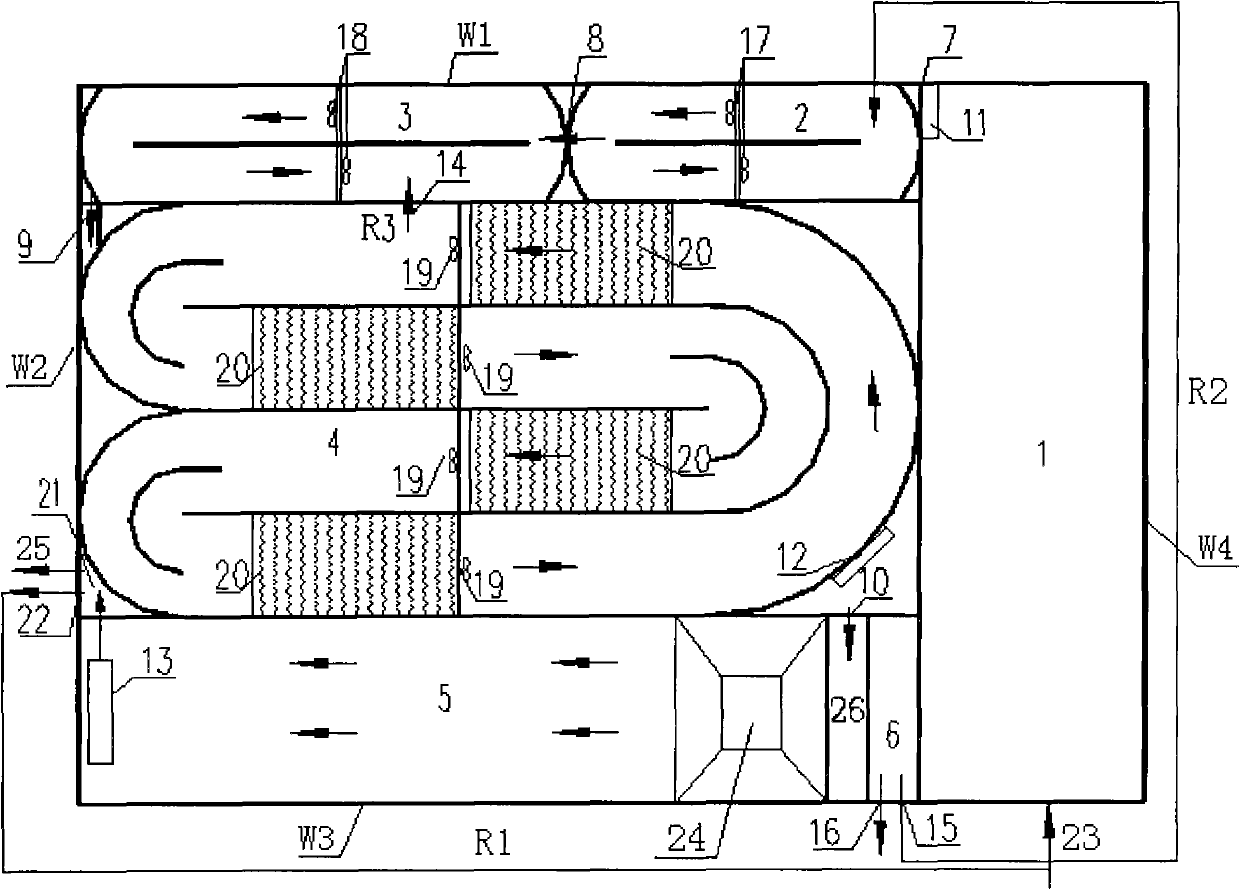

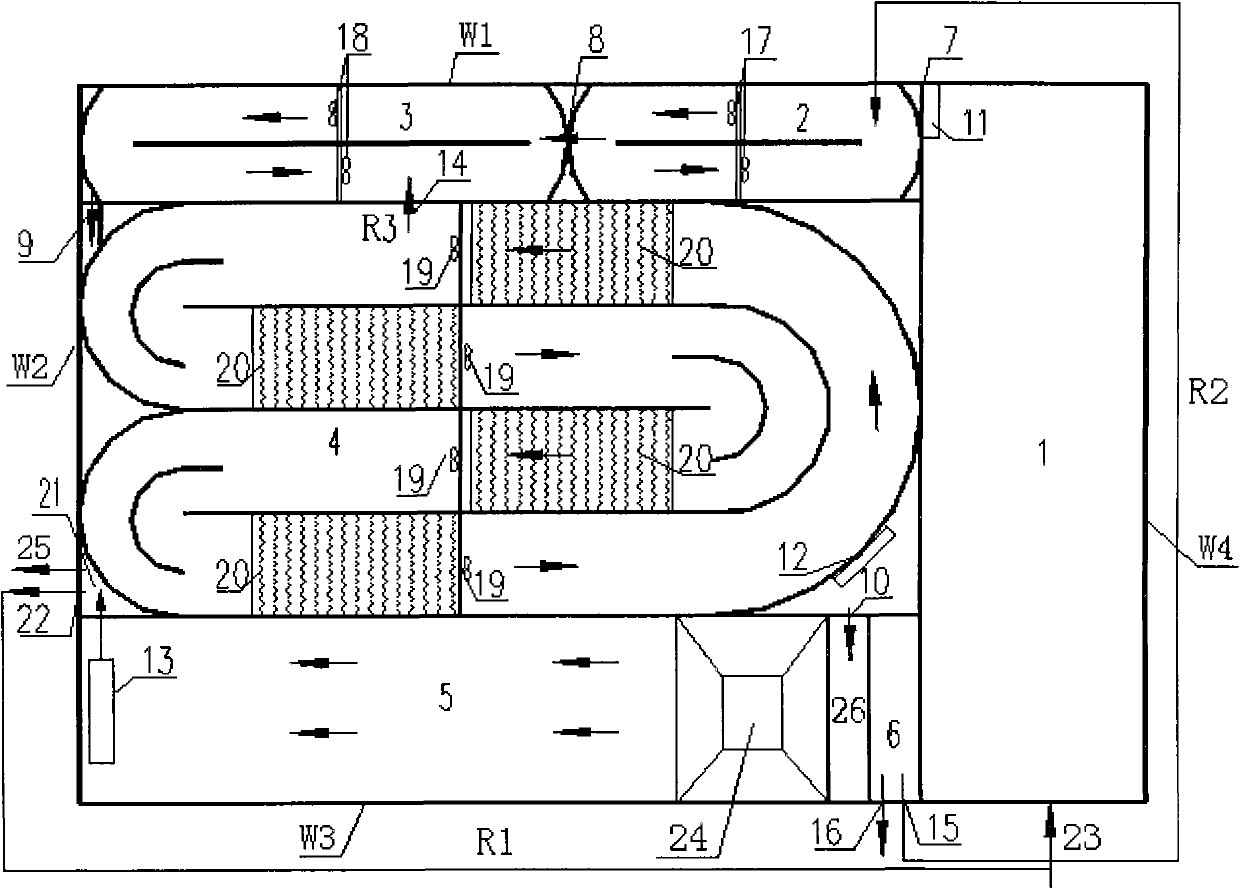

[0035] figure 1 A schematic diagram showing the structure of an anaerobic microporous aerated oxidation ditch reactor according to an embodiment of the present invention.

[0036] Such as figure 1As shown, the anaerobic microporous aerated oxidation ditch reactor in this implementation includes a plurality of treatment areas that are adjacent to each other and hydraulically connected to each other. The plurality of treatment zones include a hydrolysis zone 1 , an anaerobic zone 2 , an anoxic zone 3 , an aerobic zone 4 , a sedimentation zone 5 and a sludge storage tank 6 . The above multiple processing areas are rationally arranged to form a total area of the reactor which is similar to a rectangle and surrounded by the outer walls W1-W4 of the reactor. In this embodiment, the outer wall W1 of the reactor near the anaerobic zone 2 and the anoxic zone 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com