Quick removal of mercaptans from hydrocarbons

A technology for removal amount and hydrocarbon fluid, which is applied in refining hydrocarbon oil, treating hydrocarbon oil, purification/separation of hydrocarbon, etc., and can solve the problem of too slow removal of mercaptan remover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

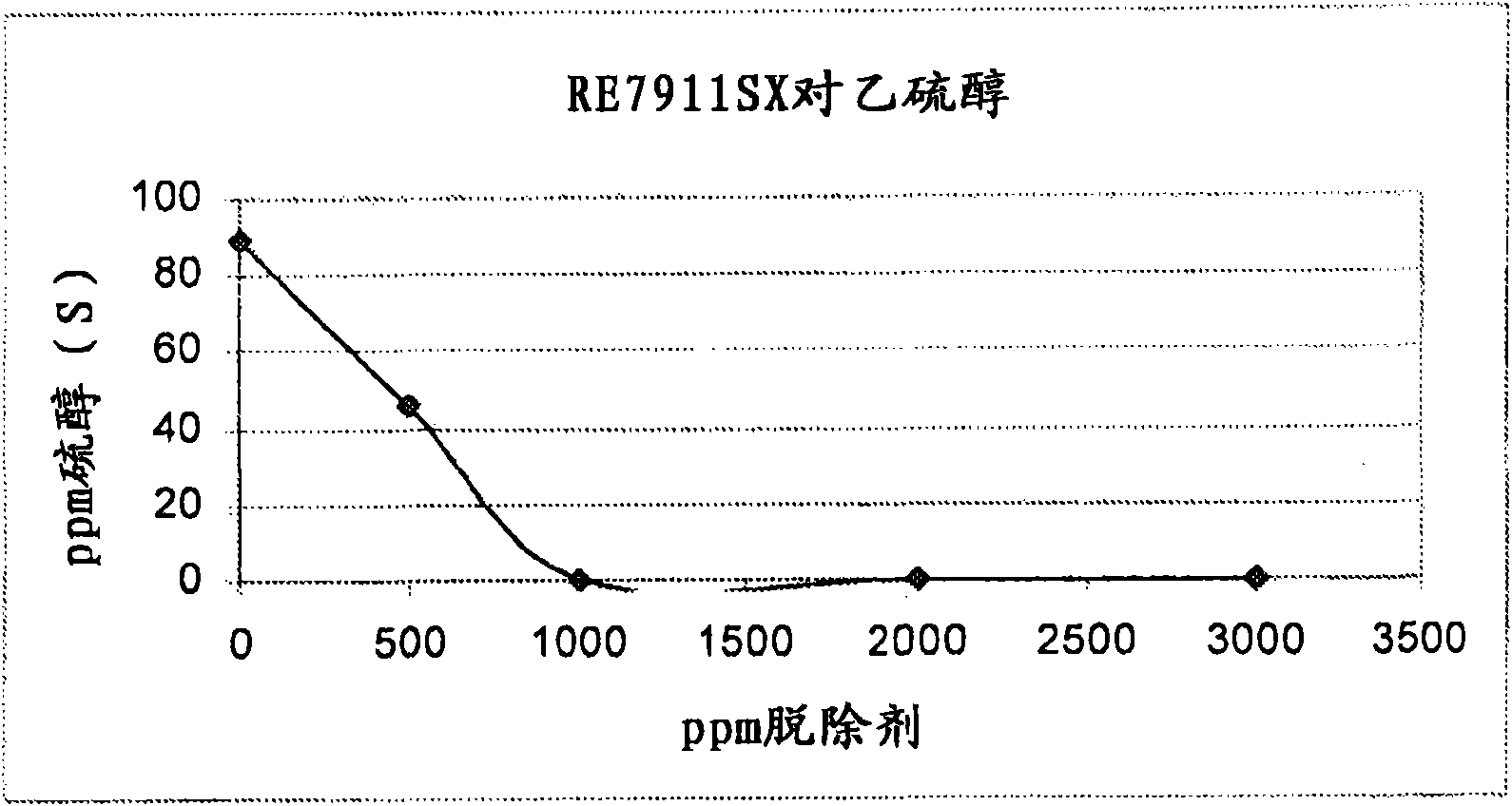

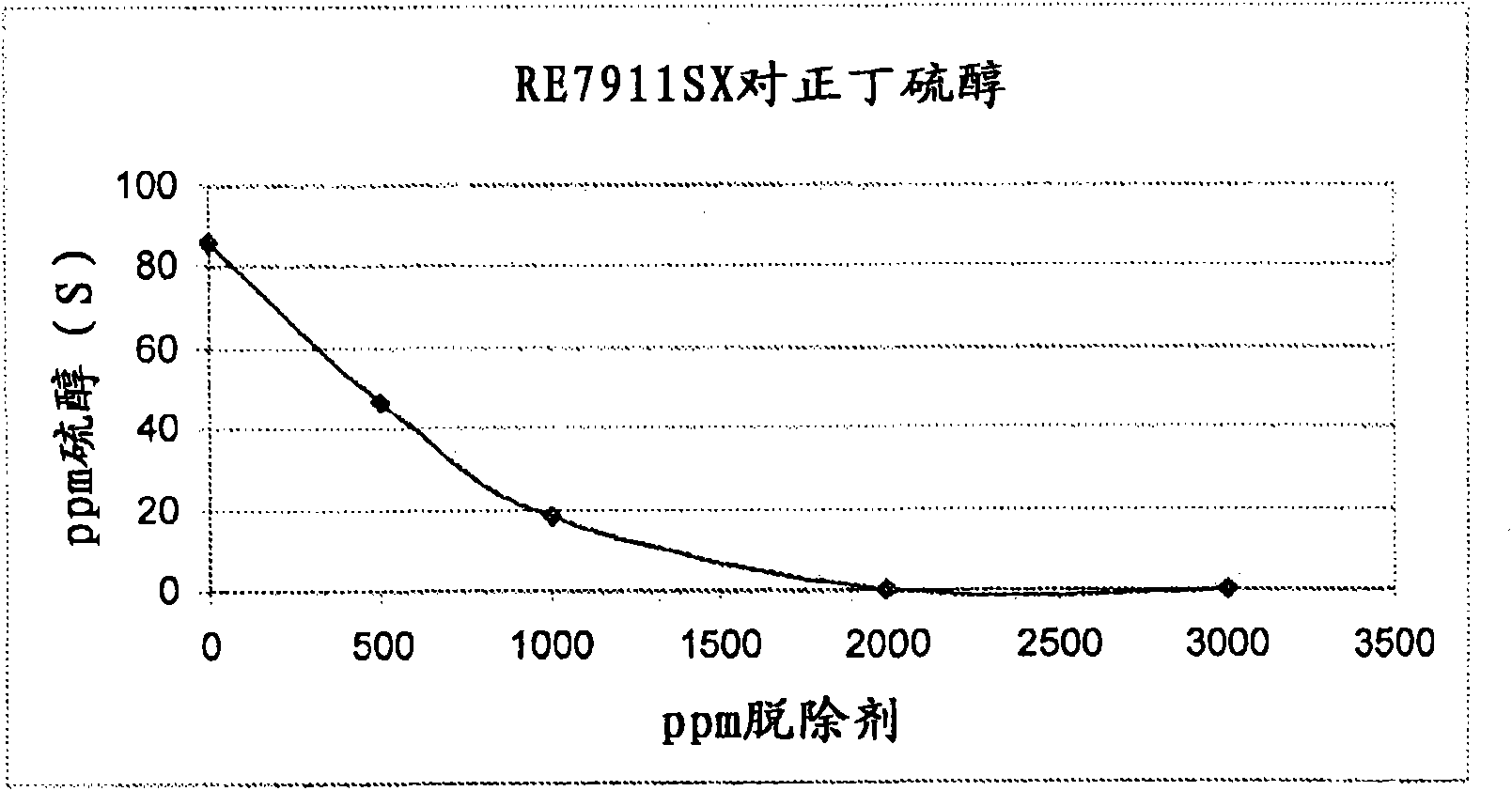

[0024] figure 1 and figure 2 Shown in is a graph of mercaptan content as a function of the amount of mercaptan removal agent present. figure 1 is ethanethiol (embodiment 1), figure 2 is n-Butanethiol (Example 2). In both cases, the hydrocarbon fluid from which the mercaptans were removed was a blend of hexane and toluene. The dialkyl azodicarboxylate mercaptan removal agent named RE7911HSO is diethyl azodicarboxylate, which is added to the mercaptan-containing hydrocarbon at a ratio of 40 wt% in the aromatic solvent Aromatic 100.

[0025] Depend on figure 1 It can be seen that when the dosage of the removal agent is 1000ppm and higher, all ethanethiol is removed from the hydrocarbon; by figure 2 It can be seen that all n-butanethiol is removed from hydrocarbons when the dosage of stripper is 2000 ppm and higher.

Embodiment 3

[0027] In another example, a C3 mercaptan dosing Aromatic 100 / toluene blend was treated with dipropyl azodicarboxylate (DIAD, 40 wt%). Aromatic 100 is available from ExxonMobil Chemical Company. The blend was stirred for 1 hour after mixing at room temperature. The results are shown in Table I. It can be seen that all the mercaptans were removed from the blend when the dosage of different strippers was 2000 ppm.

[0028] Table I

[0029] additive

Embodiment 4

[0031] In Example 4, 328 ppm of a complex mixture of mercaptans was added to Caspian crude oil, which was then treated with RE7911 HSO remover at the dosage indicated in Examples 1 and 2. The blend was stirred for 3 hours after mixing at room temperature. The results are shown in Table II. It can be seen that the amount of mercaptans removed from the blend increases with increasing removal agent dosage.

[0032] Table II

[0033] additive

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com