Trench metal-oxide-semiconductor field effect transistor (MOSFET) with shallow trench structure and manufacturing method thereof

A shallow trench and trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as short circuit between metal plugs and epitaxial layers, increase in device Rds, etc., and achieve BV reduction, Rds reduction, The effect of reducing Qg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The invention is explained in more detail below with reference to the accompanying drawings, in which preferred embodiments of the invention are shown. The invention can, however, be embodied in different ways and should not be limited to the embodiments described herein. For example, the description here refers more to N-channel trench MOSFETs, but clearly other devices are possible.

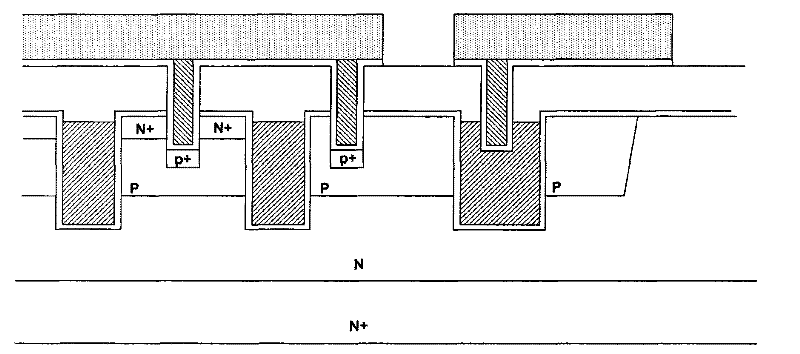

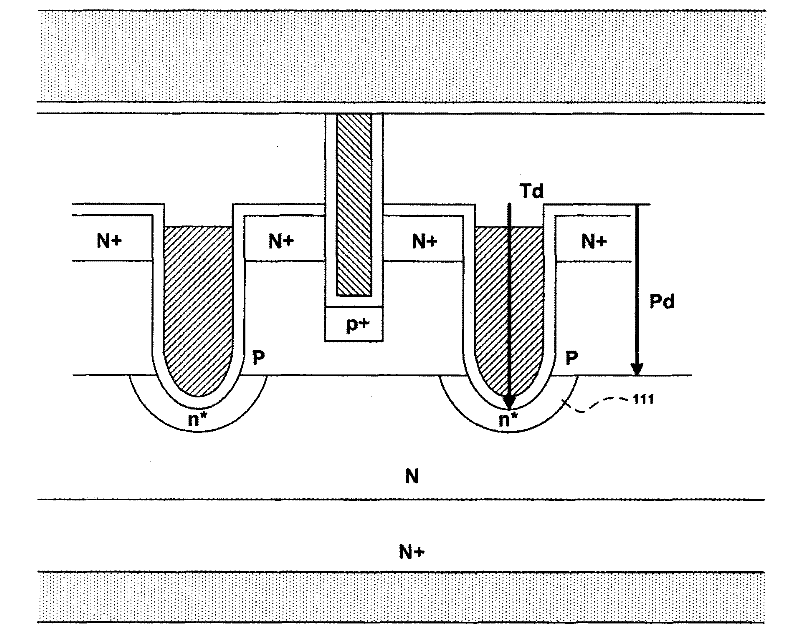

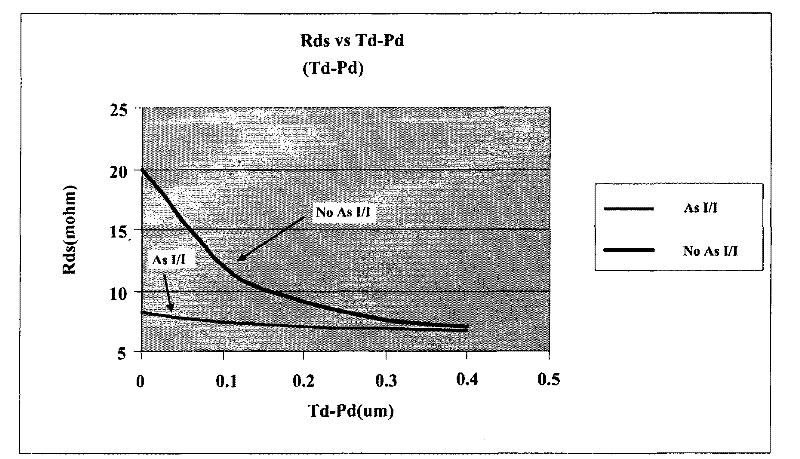

[0057] refer to Figure 5 In a preferred embodiment of the present invention shown, an N-type epitaxial layer 201 is formed on an N+ substrate 200, and the inner surface of a trench formed in the epitaxial layer is lined with a gate oxide 220 and filled with doped The polysilicon respectively forms the first trench gate 210 in the active region and the second trench gate 211 connected to the gate metal. Preferably, the width of the second trench gate 211 is greater than or equal to the width of the first trench gate 210 . Around the bottom of each trench gate 210 and 211 , and on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com