Screw-type hot cathode fluorescent tube and manufacturing method thereof

A manufacturing method and technology of fluorescent tubes, applied in cold cathode manufacturing, tube/lamp screen manufacturing, electrode system manufacturing, etc., can solve problems such as irregular slurry, dripping, and difficult slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments will be described below in conjunction with the accompanying drawings.

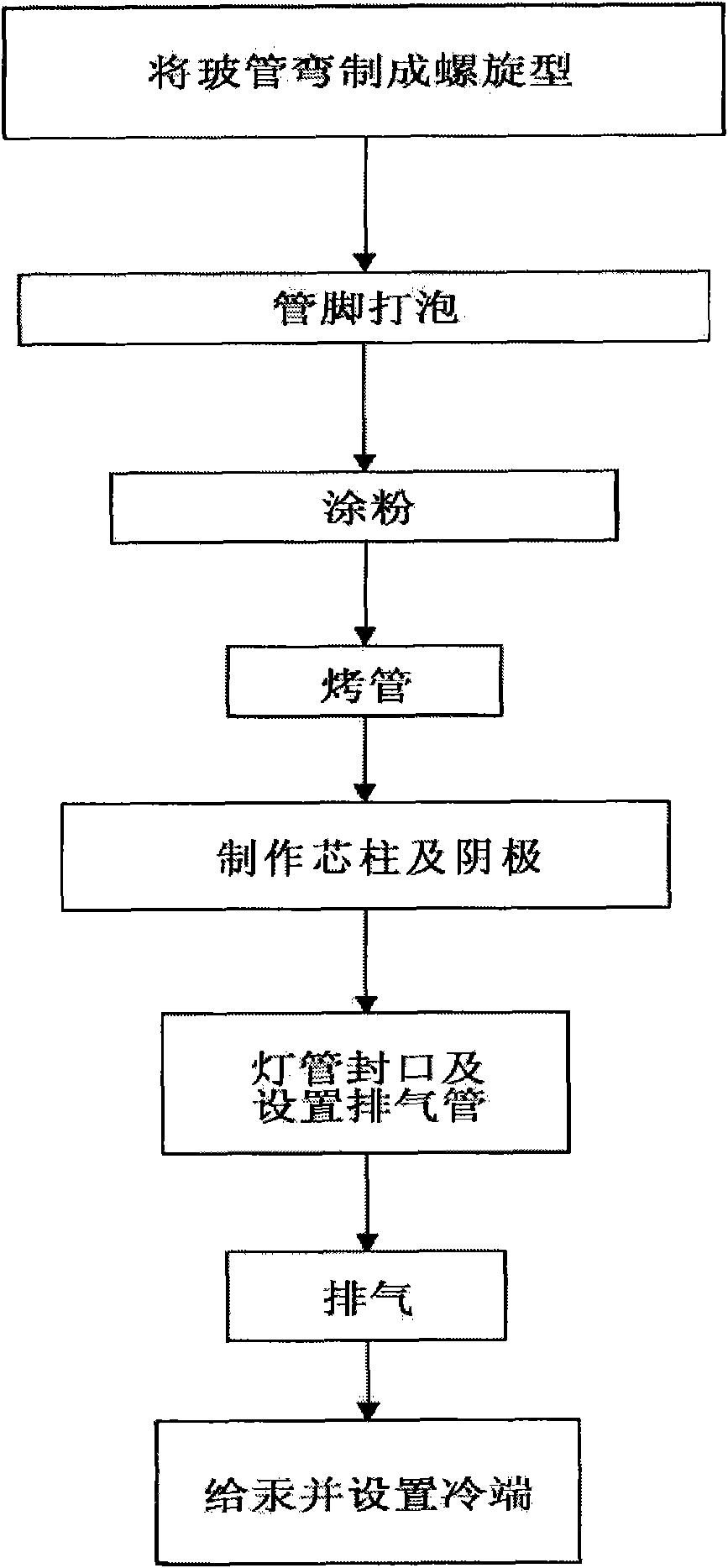

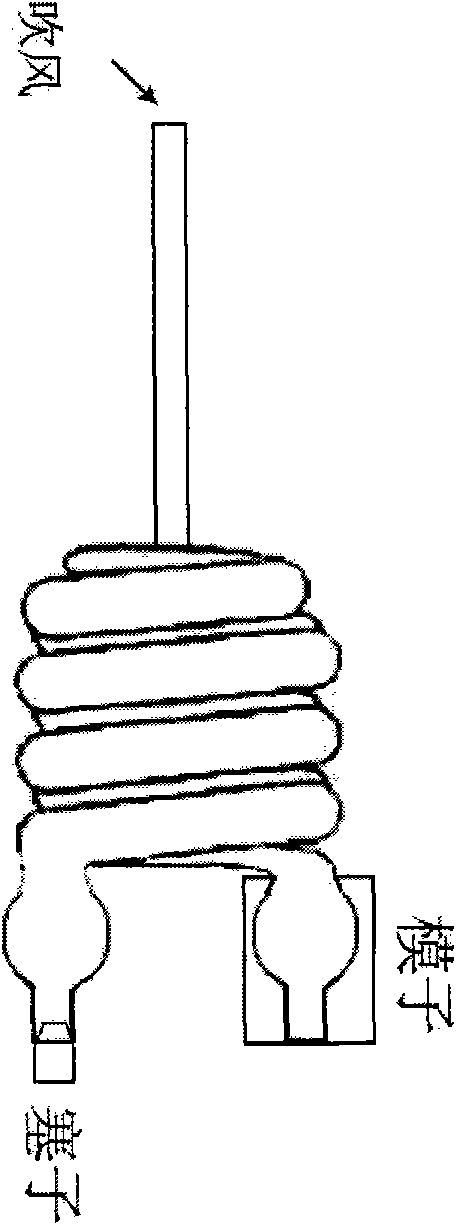

[0039] figure 1 A flow chart of a method of manufacturing a spiral hot cathode fluorescent lamp according to the present invention is shown. Such as figure 1 As shown, the present embodiment adopts the following steps: glass tube bending and molding, tube pin foaming, powder coating, tube baking, making stem and cathode, lamp tube sealing and setting exhaust pipe, exhaust, and Give mercury and set the cold junction.

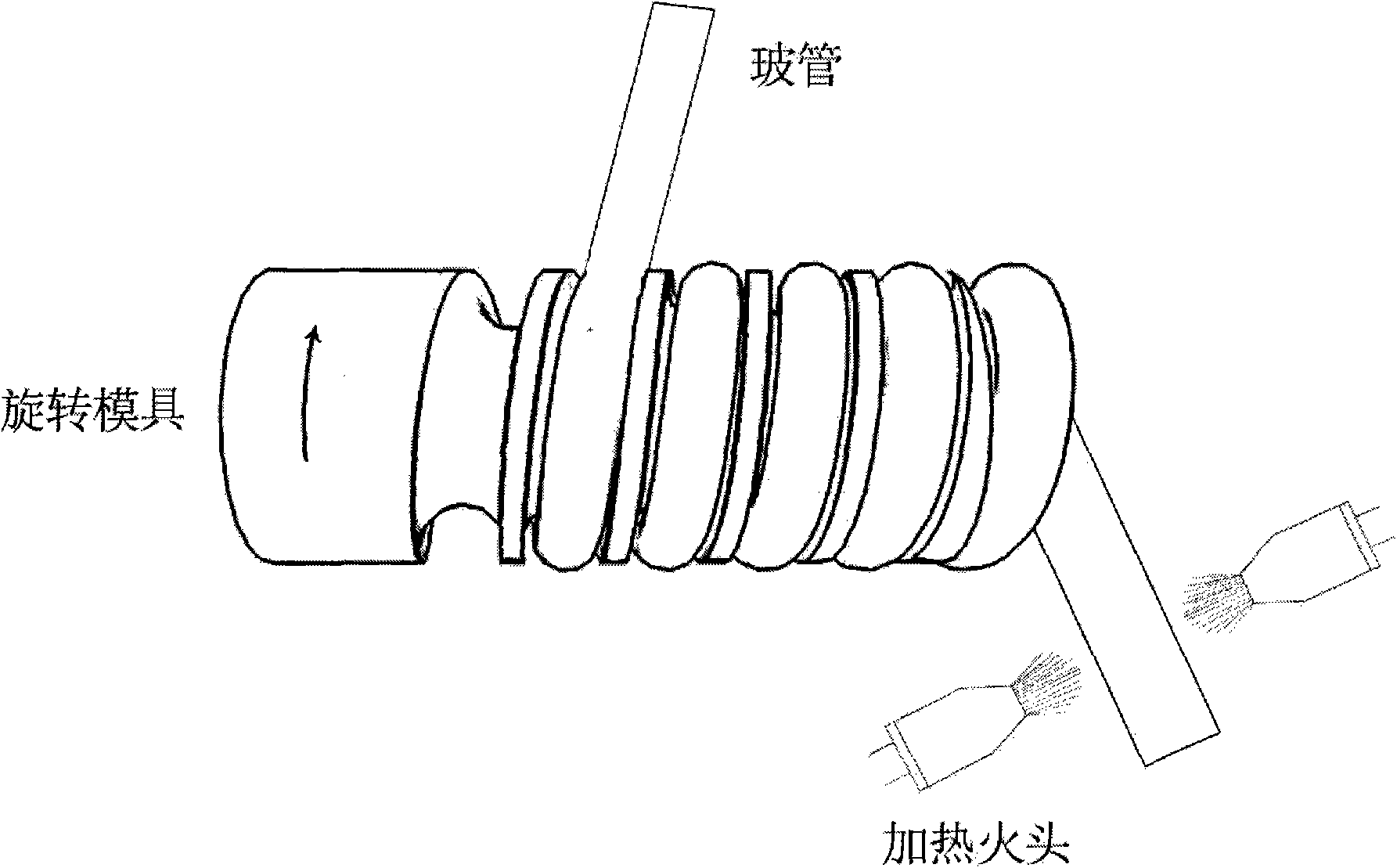

[0040] Such as figure 1 As shown, the first step of this embodiment is to bend the glass tube into shape. In this step, in the case of manufacturing double-helix fluorescent tubes, the existing method of bending large-diameter tubes can be used, that is, the straight tubes are heated in a furnace as a whole, and then manually or mechanically taken out. , hovering from the middle to both sides on the mold. In the case of manufacturing a single-helix lamp tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com