Method for flexibly adjusting catalytic cracking reaction-regeneration system heat balance

A regenerative system and heat balance technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of fixed heat load, impact, and average density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

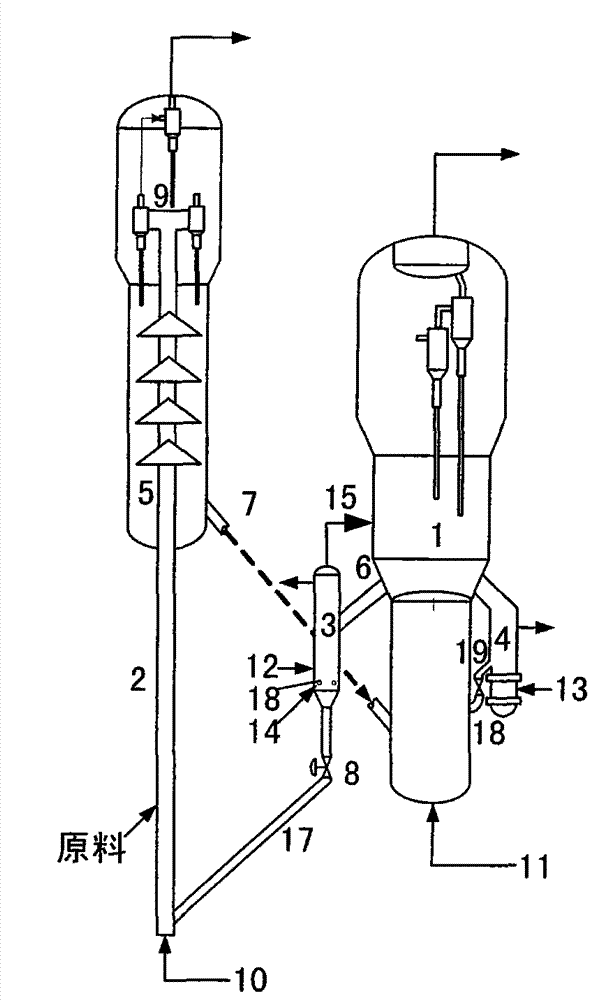

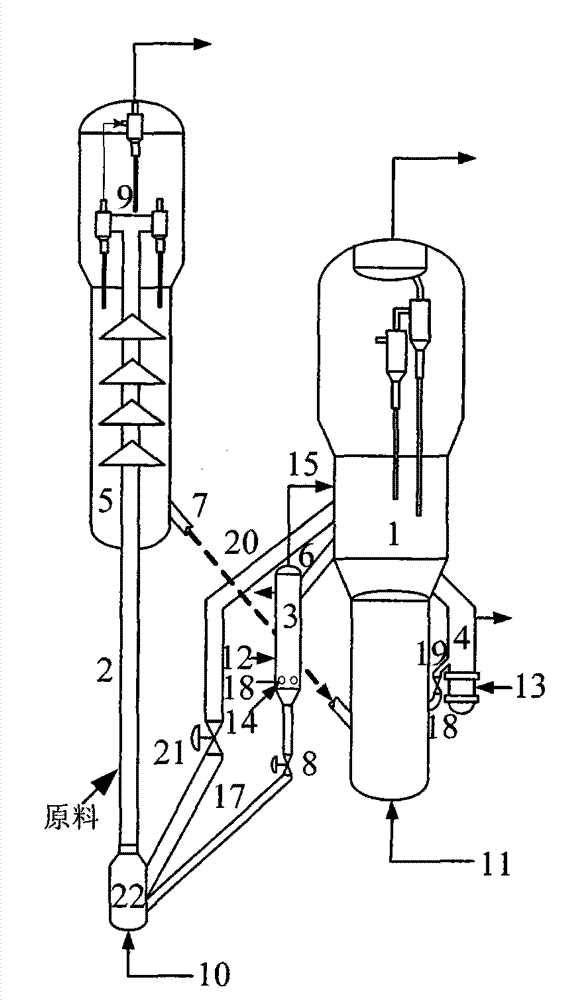

[0023] The process of the present invention can also be seen figure 2 , briefly described as follows: a conventional catalyst heat taker 4 is set on the regenerator 1 of the heavy oil catalytic cracking unit, and a part of the high-temperature catalyst in the regenerator 1 (accounting for 1% to 20% of the regenerator catalyst reserve) enters the conventional catalyst to take heat The heat exchanger 4 exchanges heat with the cooling medium 13 (water or low-pressure steam) and returns to the regenerator through the catalyst delivery pipe 18 and the catalyst flow control valve 19. The opening degree is adjusted, and the heat extraction is adjusted by the circulation amount of the catalyst entering the heat extractor and the flow rate of the cooling medium 13 (water or low-pressure steam). The low temperature catalyst (550~660℃) returned to the regenerator is mixed with the high temperature catalyst in the regenerator, so as to realize the adjustment of the catalyst bed temperatu...

specific Embodiment approach 3

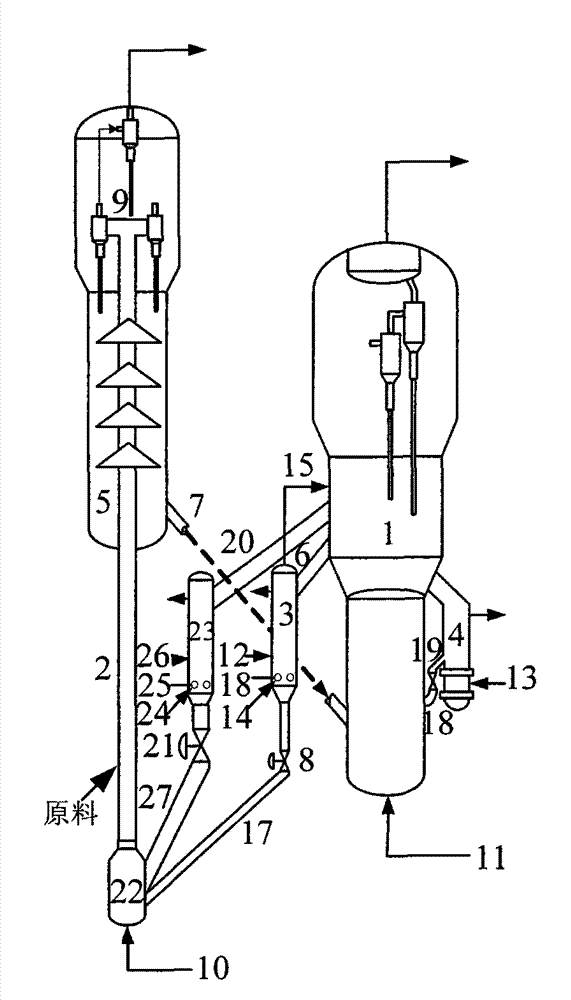

[0027] The process of the present invention can also be seen image 3 , briefly described as follows: a conventional catalyst heat taker 4 is set on the regenerator 1 of the heavy oil catalytic cracking unit, and a part of the high-temperature catalyst in the regenerator 1 (accounting for 1% to 20% of the regenerator catalyst reserve) enters the conventional catalyst to take heat The heat exchanger 4 exchanges heat with the cooling medium 13 (water or low-pressure steam) and returns to the regenerator through the catalyst delivery pipe 18 and the catalyst flow control valve 19. The opening degree is adjusted, and the heat extraction is adjusted by the circulation amount of the catalyst entering the heat extractor and the flow rate of the cooling medium 13 (water or low-pressure steam). The low temperature catalyst (550~660℃) returned to the regenerator is mixed with the high temperature catalyst in the regenerator, so as to realize the adjustment of the catalyst bed temperatur...

Embodiment 1

[0037] For verifying the effect of the present invention, adopt figure 2 The technological process shown is carried out industrial test on a 400,000 ton / year heavy oil catalytic cracking unit of a refinery, and the test results are listed in Table 1.

[0038] After adopting this invention, under the condition that the catalyst bed temperature of the regenerator is kept at 690°C, the regenerated catalyst entering the riser reactor is cooled to 660°C, the oil agent mixing temperature is 560°C, and the agent-oil ratio is increased from 6 to 9, The reaction temperature was maintained at 490°C, so that the yield of light oil increased by 2.3 percentage points, and the yield of dry gas and coke decreased significantly. See Table 1 for details.

[0039] Table 1 Properties of heavy oil raw materials

[0040] project

data

project

data

Density(20℃)kg / m 3

945

Nitrogen content, ppm

2000

Carbon residue, wt%

5.4

Hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com