Alkali-soluble polymer, photosensitive resin composition comprising the same, and uses of the same

A technology of alkali-soluble polymers and photosensitive resins, which is applied in the field of photosensitive resin compositions, and can solve problems such as low glass transition temperature, large curing shrinkage, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

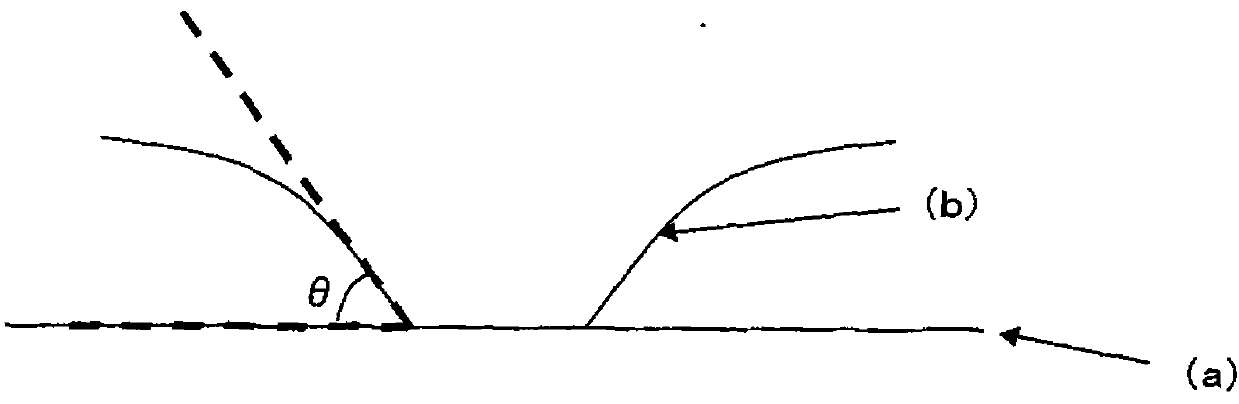

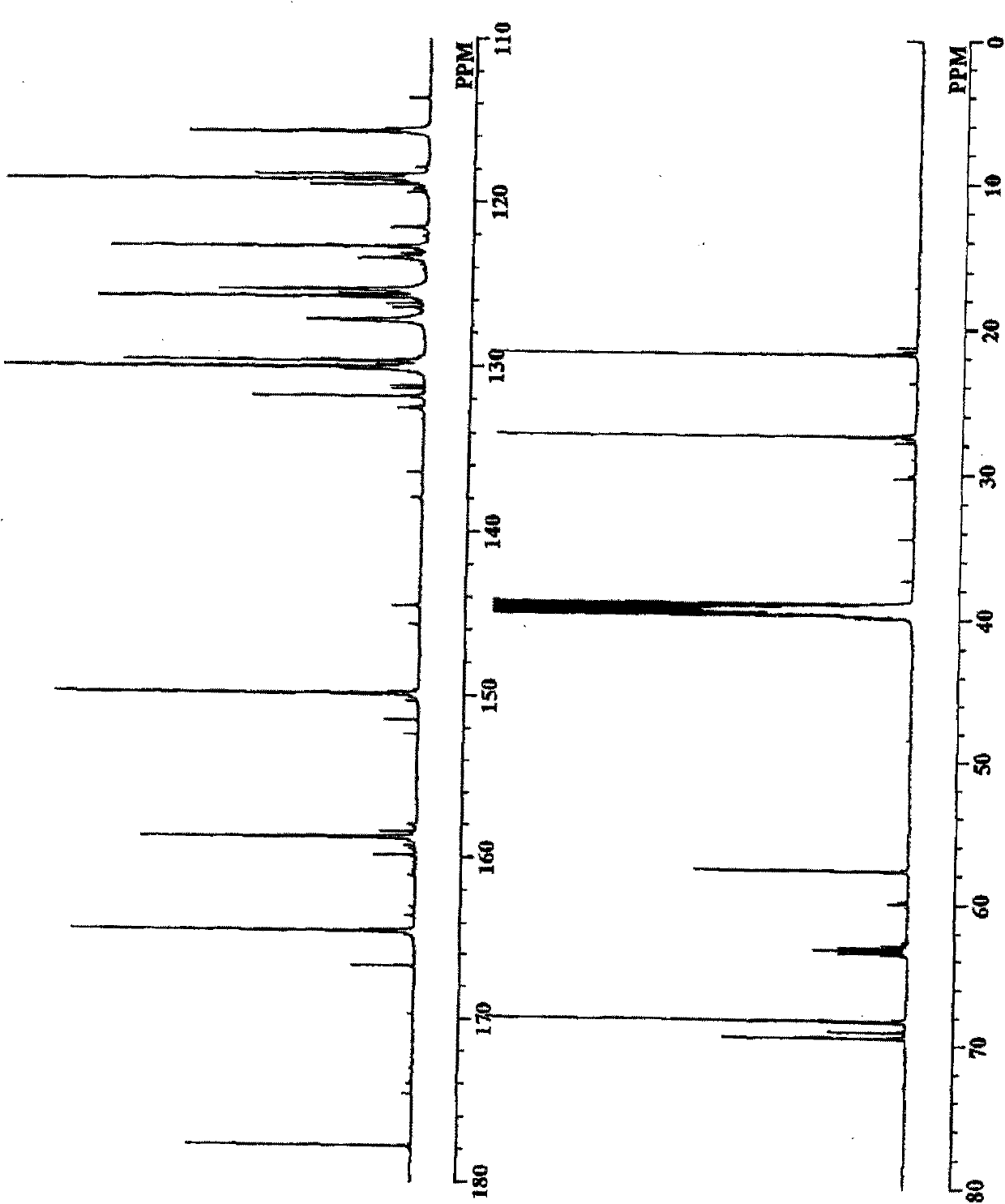

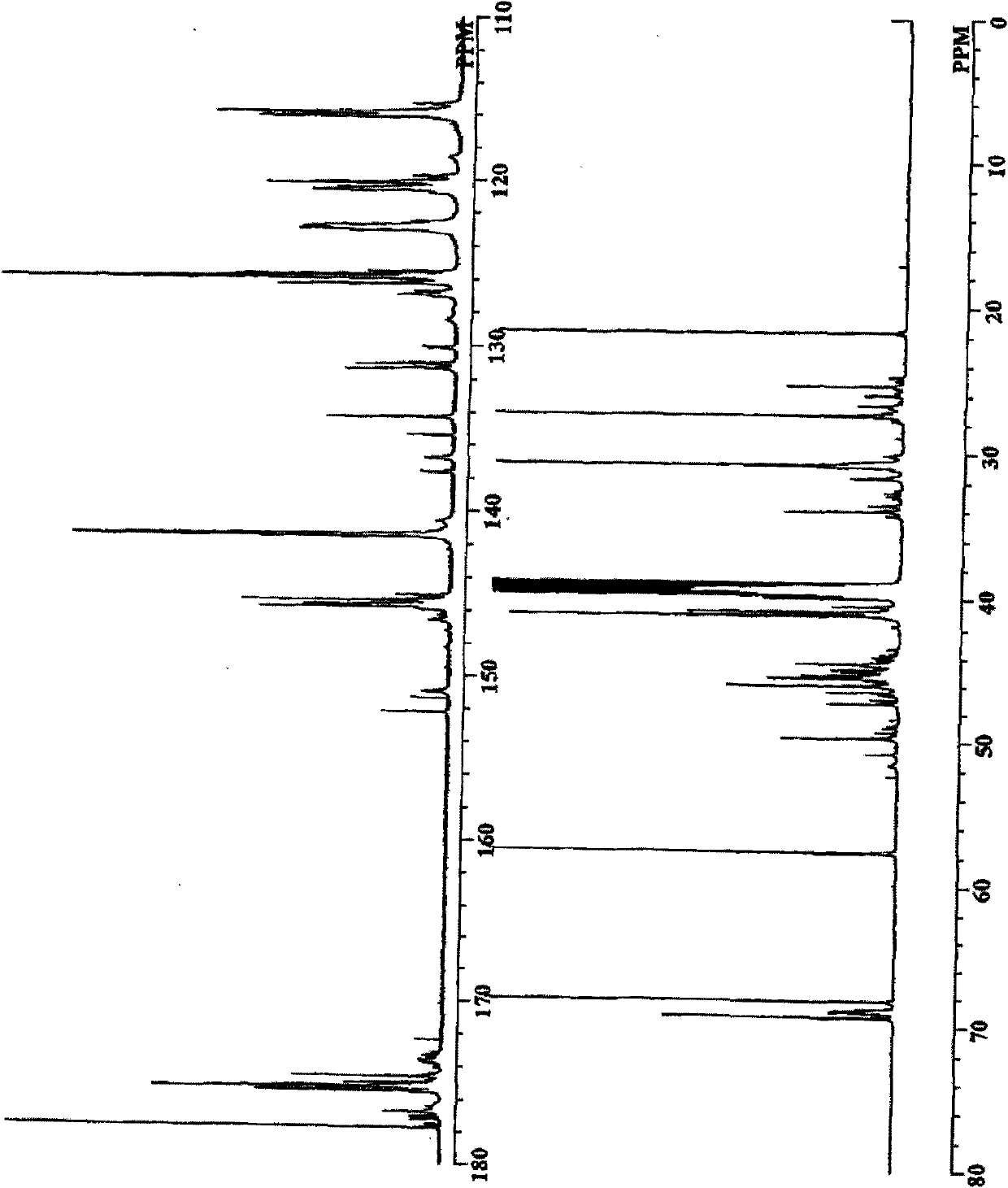

Image

Examples

Embodiment

[0497] Hereinafter, the present invention will be described based on reference examples, examples, and comparative examples.

[0498] Bis (carboxy) tricyclic [5, 2, 1, 0 2,6 ] Manufacture of decane

reference example 1

[0500] In a detachable three-necked glass flask equipped with an anchor stirrer made by Teflon (registered trademark), add 71.9g (0.366mol) tricyclic [5,2,1,0 2,6 ] Decanedimethanol (manufactured by Tokyo Chemical Industry Co., Ltd.) dissolved in 1L of acetonitrile, 256.7g (1.808mol) of disodium hydrogen phosphate and 217.1g (1.809mol) of sodium dihydrogenphosphate were dissolved in 1.4L of ion-exchanged water obtained substance. 2.8 g (0.0179 mol) of 2,2,6,6-tetramethylpiperidine-1-oxyl (manufactured by Tokyo Chemical Industry Co., Ltd., hereinafter also referred to as "TEMPO") was added thereto, and stirred to dissolve.

[0501] 143.2 g (1.267 mol) of 80% sodium chlorite was diluted with 850 mL of ion-exchanged water, and this was added dropwise to the reaction liquid. Next, what diluted 3.7 mL of 5% sodium dichlorite aqueous solution with 7 mL of ion-exchanged water was dripped at the reaction liquid. The reaction liquid was kept at 35-38° C. by a constant temperature lay...

reference example 2

[0505] Two (carboxy) tricyclic [5,2,1,0 2,6 ] Decane, 97mL (1.33mol) of thionyl chloride, and 0.4mL (5.0mmol) of pyridine were added to the reaction vessel, stirred at 25-50°C for 18 hours, and allowed to react. After the reaction was finished, toluene was added, and the excess thionyl chloride was azeotroped with toluene to concentrate under reduced pressure to obtain 73.3 g (yield 100%) of oily bis(chlorocarbonyl)tricyclo[5,2,1, 0 2,6 ] Decane.

[0506] Synthesis of Photoacid Generator (B) Naphthoquinonediazide Compound

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com