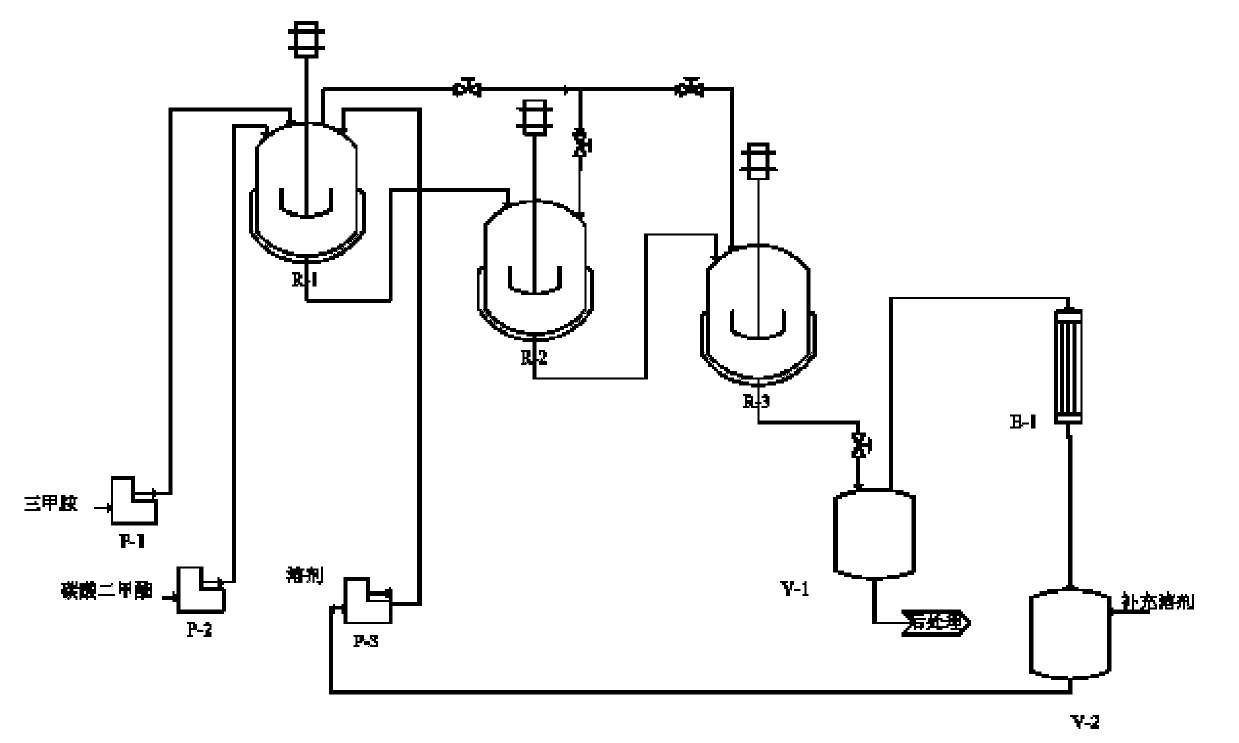

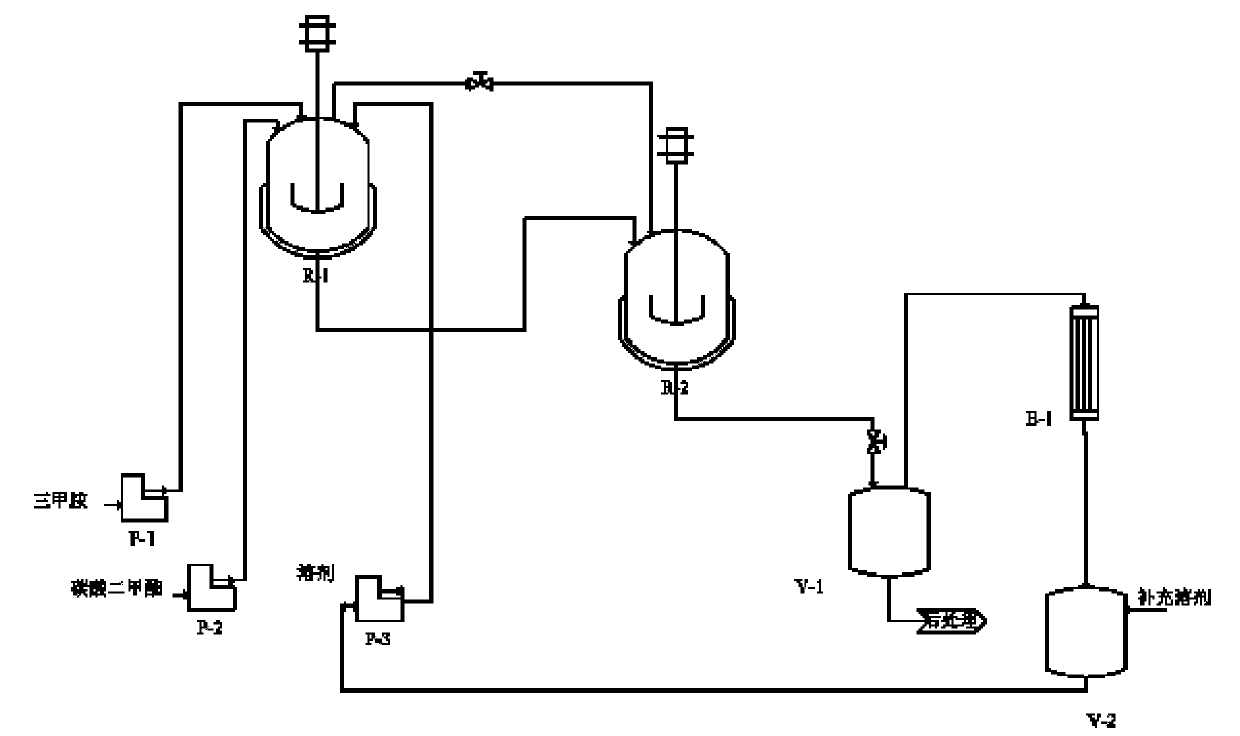

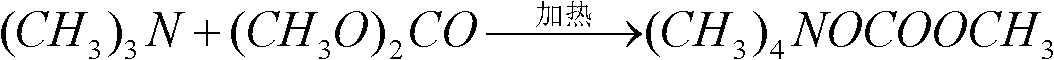

Method and device of continuously synthesizing tetramethyl ammonium carbonate by multi-reactors in series

A technology of multiple reactors connected in series and tetramethylammonium, applied in the preparation of amino compounds from amines, chemical/physical/physicochemical fixed reactors, chemical recovery, etc., can solve the problem of product quality and yield stability in the batch reaction process , Unfavorable electronic grade product TMAH, increase the probability of introducing impurity ions, etc., to achieve continuous production and automatic control, facilitate large-scale production, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Synthesize tetramethylammonium carbonate by three-stage series tank reactor, the raw material ratio is DMC: TMA: MEOH=1: 1: 6, the reaction temperature of the primary reactor is 100 ℃, the reaction of the secondary reactor The temperature is 110°C, the reaction temperature of the three-stage reactor is 120°C, the reaction pressure is 0.7MPa, the potential difference of each stage reactor is 0.5m, and the average residence time of the reaction materials in each stage is 2 hours. Sample analysis The content of tetramethylammonium ion, the yield of tetramethylammonium ion is 94.5%.

Embodiment 2

[0040] Synthesize tetramethylammonium carbonate by three-stage series tank reactor, the ratio of raw materials is DMC: TMA: MEOH=1: 0.8: 3, the reaction temperature of each stage of reactor is all the same as 90 ℃, and the reaction pressure is 0.4MPa, the potential difference of each stage reactor is 1.0 meters, the average residence time of the reaction material in each stage is 2 hours, the content of tetramethylammonium ion is sampled and analyzed, and the yield of tetramethylammonium ion is 70.0%.

Embodiment 3

[0042] Synthesize tetramethylammonium carbonate by three-stage series tank reactor, the ratio of raw materials is DMC: TMA: MEOH=1: 1.5: 8, the reaction temperature of each stage of reactor is all the same as 200 ℃, and the reaction pressure is 2.5MPa, the potential difference of each stage reactor is 0.5 meters, the average residence time of the reaction material in each stage is 2 hours, the content of tetramethylammonium ion is sampled and analyzed, and the yield of tetramethylammonium ion is 88.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com