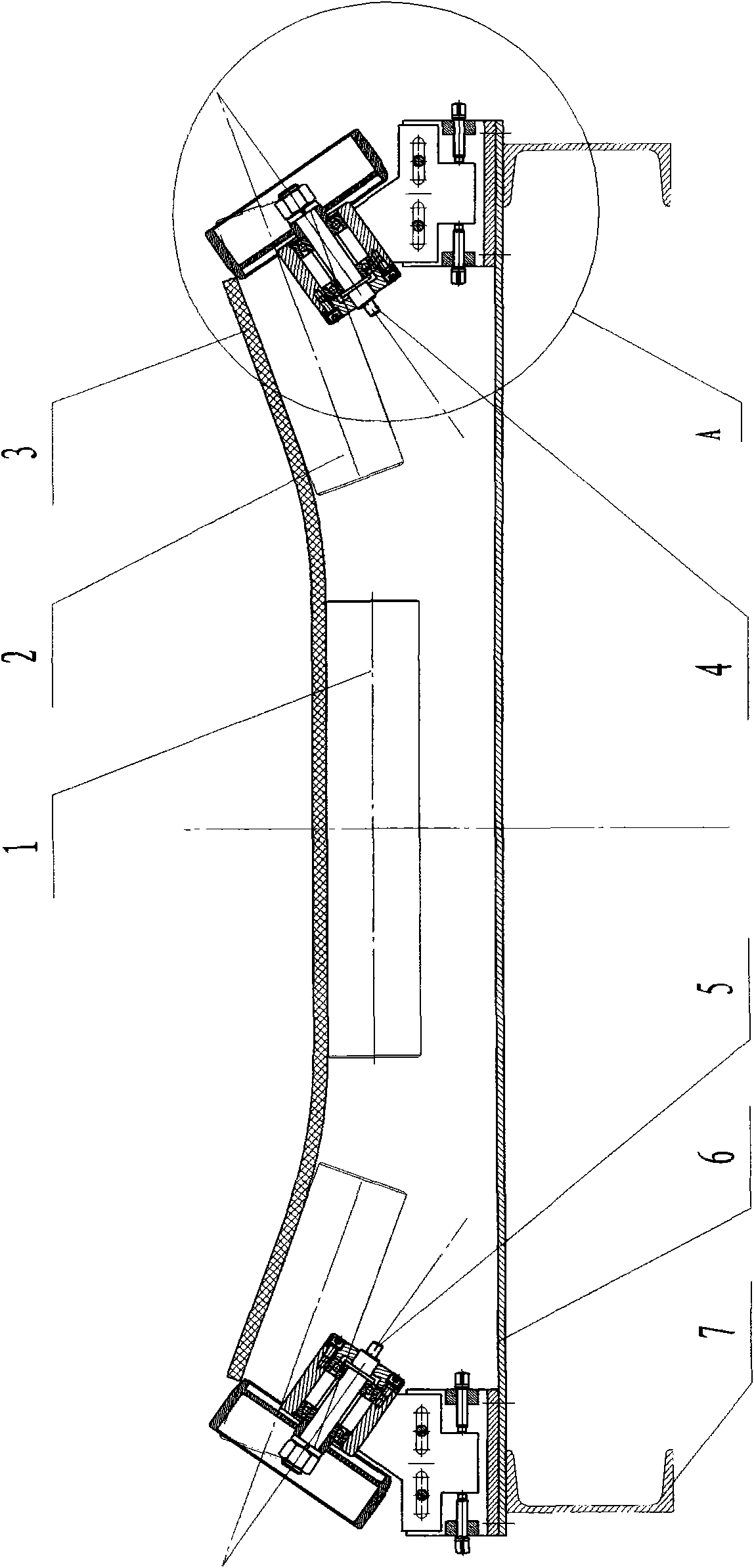

Automatic rectification machine for belt conveyer

A technology of belt conveyor and deviation correcting machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve the problems of poor deviation correction effect, high manufacturing cost, inconvenient installation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

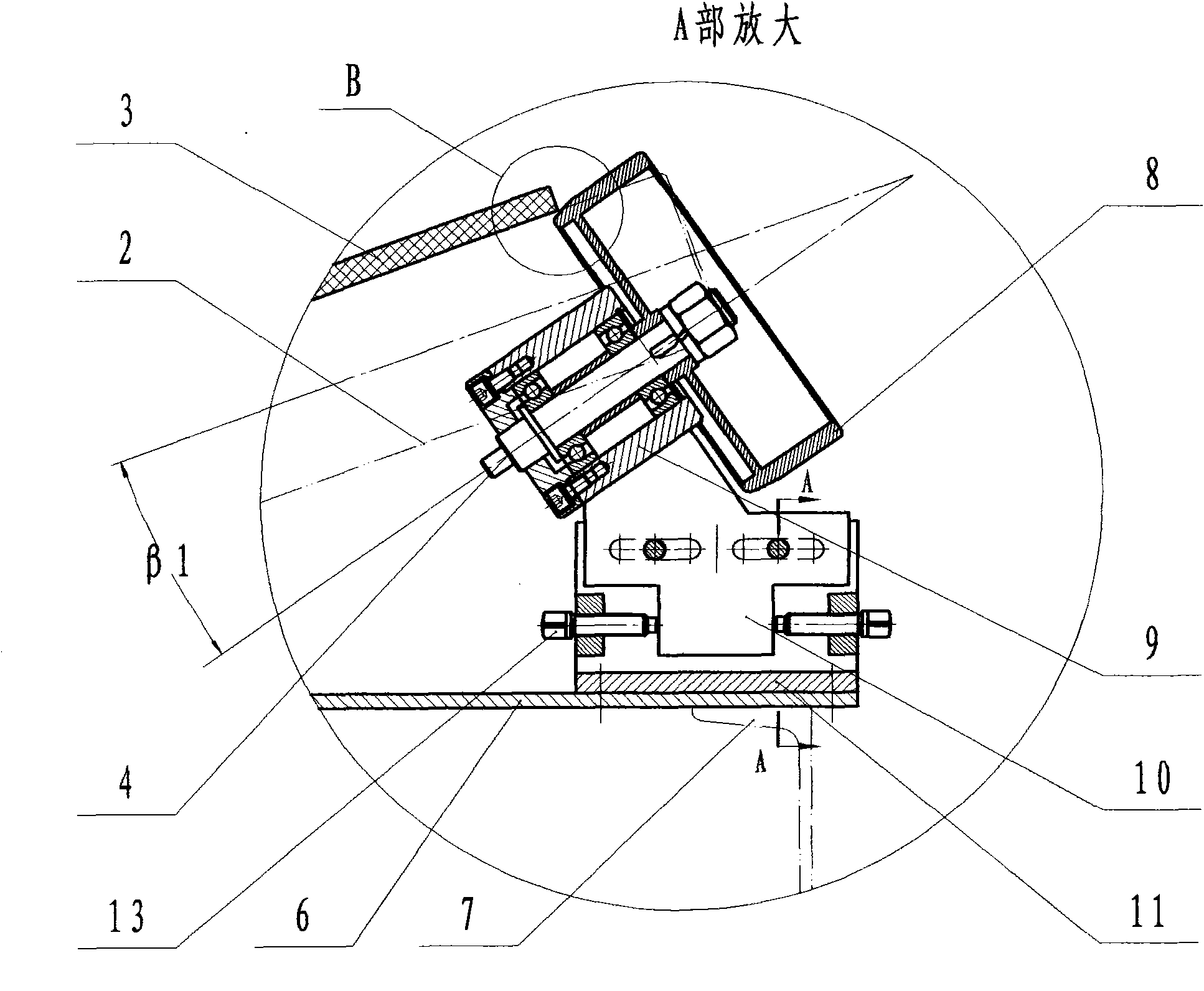

[0039] The detection idler seat frame 11 is fixedly connected with the detection idler connecting plate 6 by bolts, and the detection idler connecting plate 6 is welded or bolted fixedly connected with the frame 7 of the belt conveyor.

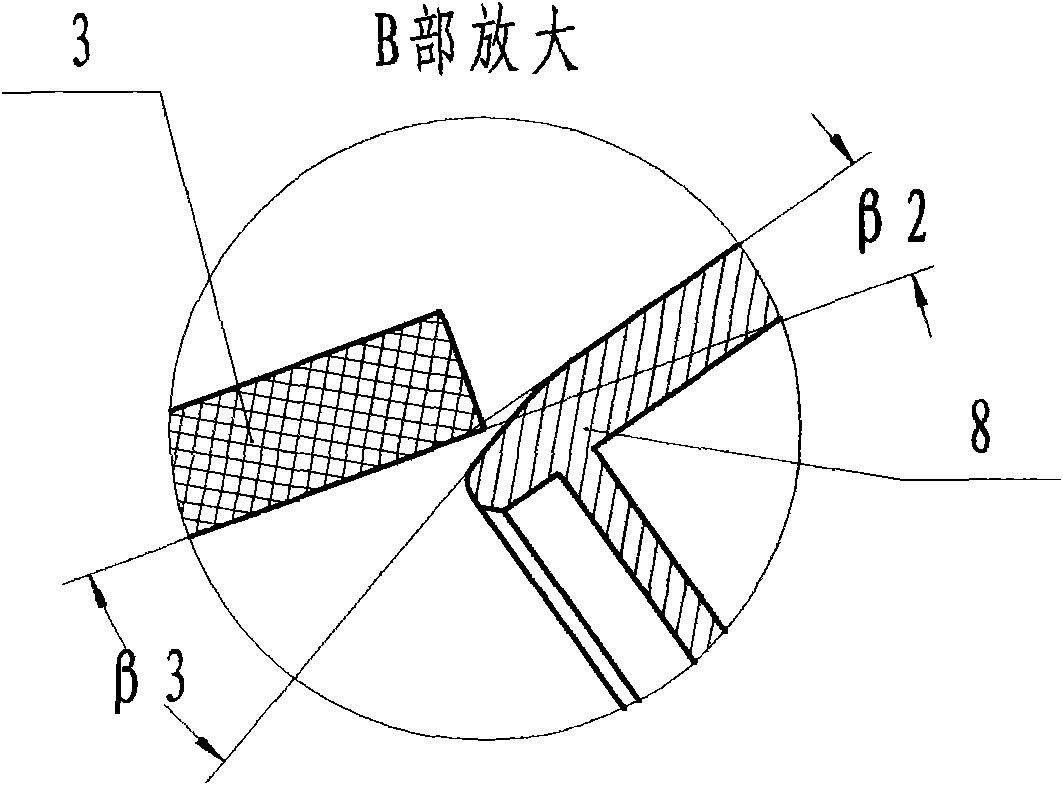

[0040] The front end of the detection idler 8 is made into a conical shape to reduce the impact on the detection idler 8 when the belt 3 deviates. The detection idler 8 is divided into two groups, arranged symmetrically. The detection idler 8 is fixedly connected with the output shaft 4 of the right detection idler or the output shaft 5 of the left detection idler, and its axis is set at an angle β1 with the inclined idler of the belt conveyor, so as to increase the friction between the belt 3 and the detection idler 8 force. The bearing sleeve 9 is welded with the bearing sleeve connecting plate 10, the bearing sleeve connecting plate 10 can slide left and right in the detection idler stand frame 11, and the bearing sleeve connecting plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com