Method for quickly preparing recombinant heat-resistant manganese superoxide dismutase

A superoxide and dismutase technology, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of less super-large pore media, limitations, and no reports of high-temperature-resistant SOD enzymes, and achieve fast separation speed and recovery The effect of high efficiency and small loss of SOD enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

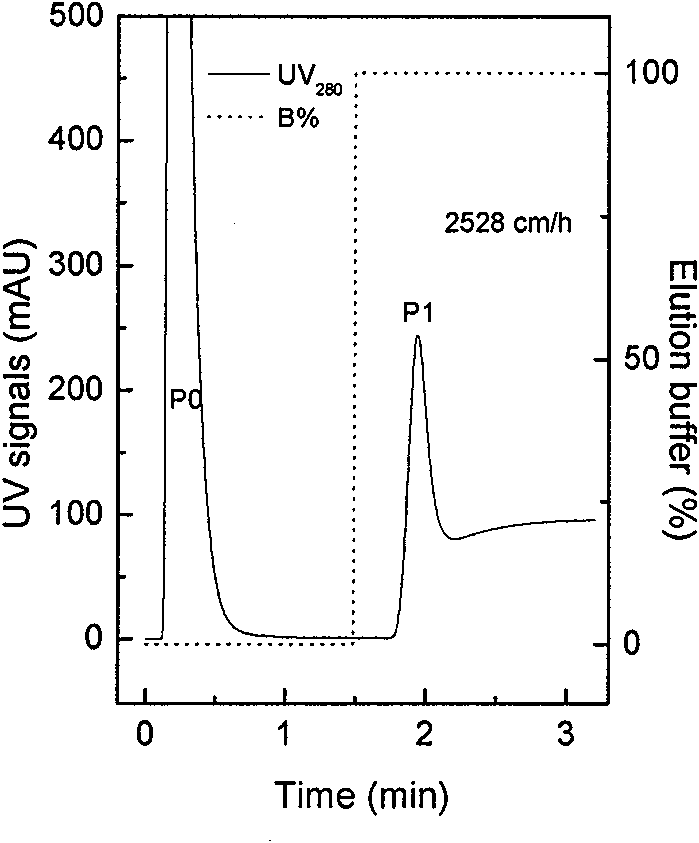

[0025] Take 500ml of fermentation broth, centrifuge for 15mm (centrifugation condition is 4°C, centrifugal force is 1000×g), wash the bacteria with 5-10ml of 1M TE Buffer (pH 8.0), centrifuge for 15min, discard the supernatant, add 1M TE Buffer (pH 8.0) TE Buffer (pH 8.0) 5ml, mix well; use an ultrasonic cell pulverizer to crush the bacteria (ultrasonic conditions: ultrasonic time 2s, interval 3s, frequency 99 times); after ultrasonication, centrifuge for 15min, the supernatant is the crude enzyme liquid. Get 5ml of crude enzyme solution, utilize sample loader to load the sample, in the semi-preparative grade ultra-large hole nickel column (300 * 10mm I.D.) that is housed Chromatographic separation on purifier 100system, separation conditions: mobile phase, 20mM phosphate buffer + 0.5M NaCl + 0.12M imidazole, pH 7.4; elution phase, 20mM phosphate buffer + 0.5M NaCl + 0.5M imidazole, pH 7.4; Elution mode, step elution; operating flow rate, 2528cm / h. Collect the elution peak ...

Embodiment 2

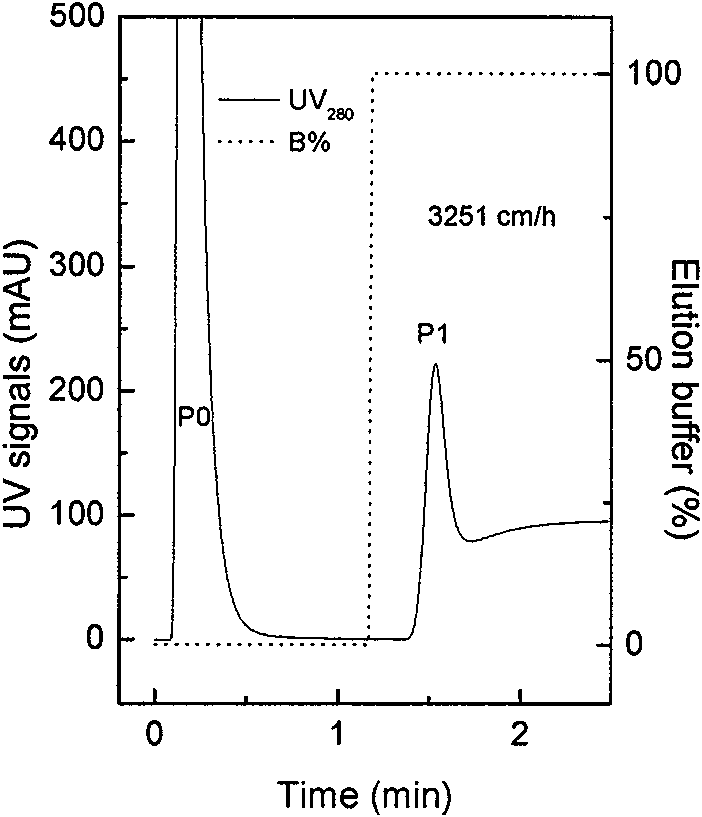

[0027] Take 500ml of fermentation broth, centrifuge for 15min (centrifugation condition is 4°C, centrifugal force is 1000×g), wash the bacteria with 5-10ml of 1M TE Buffer (pH 8.0), centrifuge for 15min, discard the supernatant, add 1M TE Buffer (pH 8.0) TE Buffer (pH 8.0) 5ml, mix well; use an ultrasonic cell pulverizer to crush the bacteria (ultrasonic conditions: ultrasonic time 2s, interval 3s, frequency 99 times); after ultrasonication, centrifuge for 15min, the supernatant is the crude enzyme liquid. Get 5ml of crude enzyme solution, utilize sample loader to load the sample, in the semi-preparative grade ultra-large hole nickel column (300 * 10mm I.D.) that is housed Chromatographic separation on purifier 100system, separation conditions: mobile phase, 20mM phosphate buffer + 0.5M NaCl + 0.1M imidazole, pH 7.4; elution phase, 20mM phosphate buffer + 0.5M NaCl + 0.5M imidazole, pH 7.4; Elution mode, step elution; operating flow rate, 3251cm / h. Collect the elution peak ...

Embodiment 3

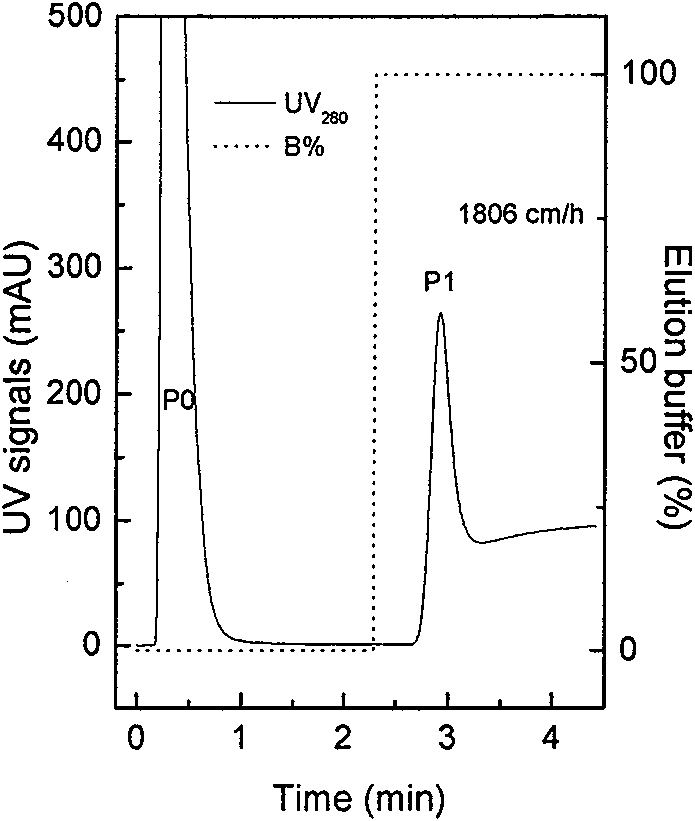

[0029] Take 500ml of fermentation broth, centrifuge for 15min (centrifugation condition is 4°C, centrifugal force is 1000×g), wash the bacteria with 5-10ml of 1M TE Buffer (pH 8.0), centrifuge for 15min, discard the supernatant, add 1M TE Buffer (pH 8.0) TE Buffer (pH 8.0) 5ml, mix well; use an ultrasonic cell pulverizer to crush the bacteria (ultrasonic conditions: ultrasonic time 2s, interval 3s, frequency 99 times); after ultrasonication, centrifuge for 15min, the supernatant is the crude enzyme liquid. Get 5ml of crude enzyme solution, utilize sample loader to load the sample, in the semi-preparative grade ultra-large hole nickel column (300 * 10mm I.D.) that is housed Chromatographic separation on purifier 100system, separation conditions: mobile phase, 20mM phosphate buffer + 0.5M NaCl + 0.1M imidazole, pH 7.4; elution phase, 20mM phosphate buffer + 0.5M NaCl + 0.1M imidazole, pH 5; Elution mode, step elution; operating flow rate, 1806cm / h. Collect the elution peak ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com