Method for laying bottom of prefabricated block ladle by using small building blocks

A technology of prefabricated blocks and small blocks, applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems that cannot be maintained or replaced locally, it is difficult to achieve basically the same performance of the bottom wrapping, and the construction labor intensity of workers is high. problems, to achieve partial maintenance or replacement, good high-temperature volume stability, and prevent accidents of bottom-coated drilling steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

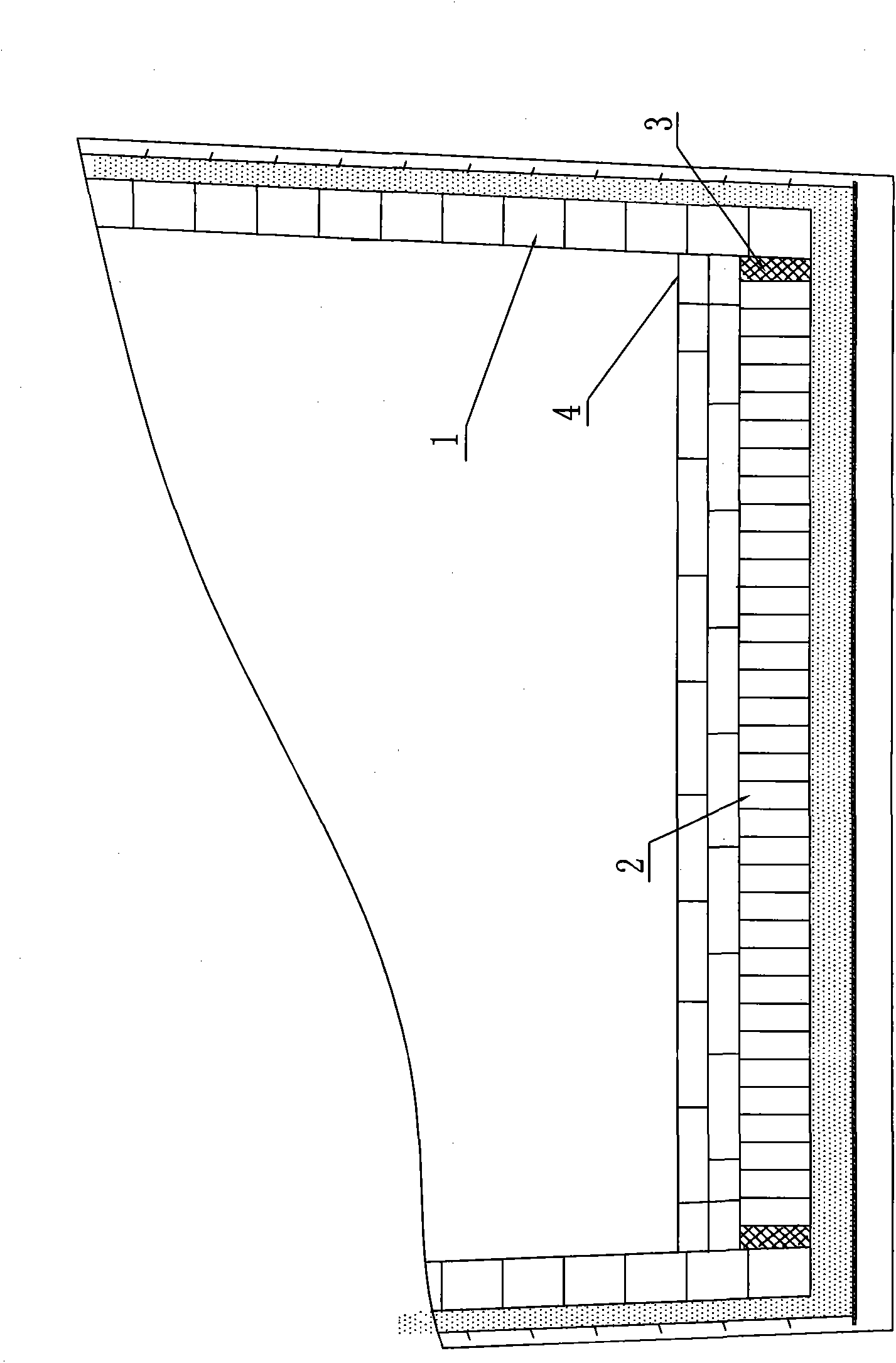

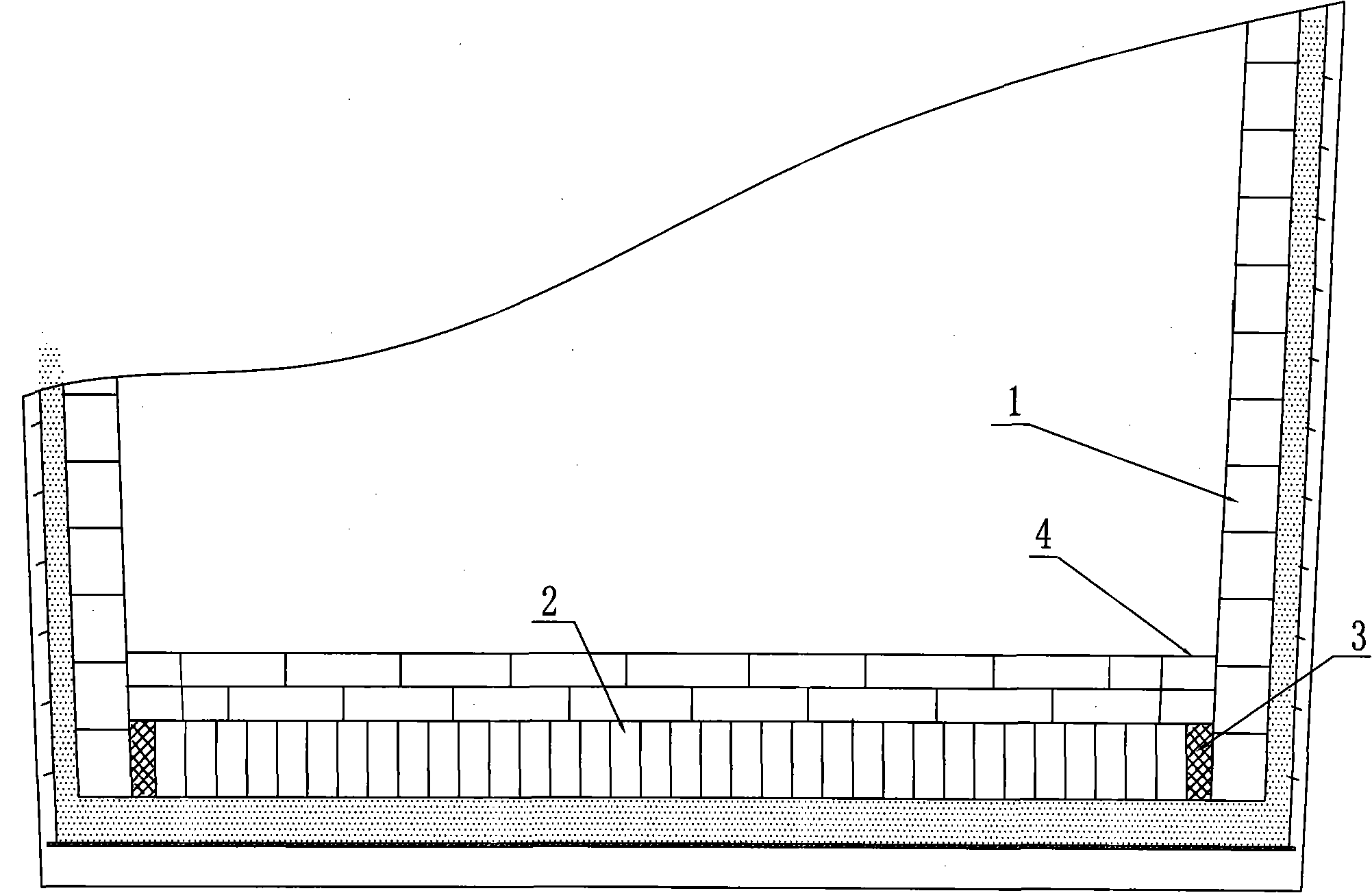

[0014] As shown in the figure, the method of using small blocks at the bottom of the prefabricated block ladle of the present invention is to use straight small prefabricated blocks 2 to vertically build the bottom of the ladle after the ladle wall lining 1 is built; the straight small The prefabricated block 2 is a rectangular refractory brick made of existing corundum spinel material, and its length, width and height are 300mm, 250mm and 100mm. During masonry, a gap of 40mm-50mm is reserved between the periphery of the bottom and the wall, and the gap is filled with corundum spinel castable 3. Two layers of corundum spinel refractory bricks 4 can be built by seams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com