Determination method of copperplate heat flux based on mass balance and heat balance continuous casting mould

A technology of continuous casting mold and determination method, applied in the direction of material thermal development, etc., can solve the problems of inability to accurately give the boundary conditions of heat flux density, lack of flexibility and timeliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

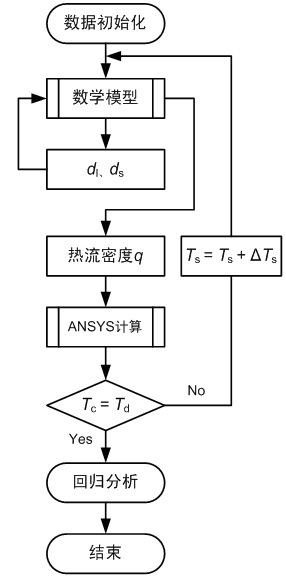

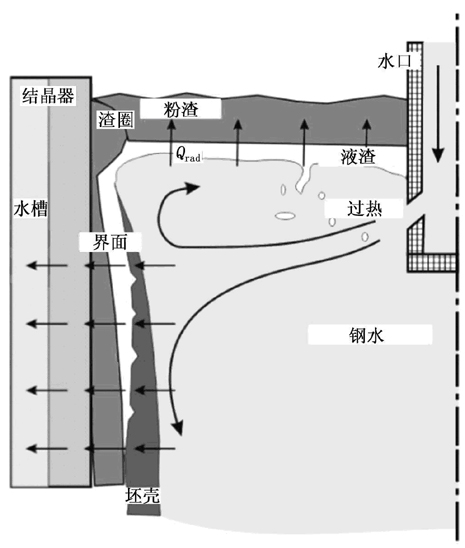

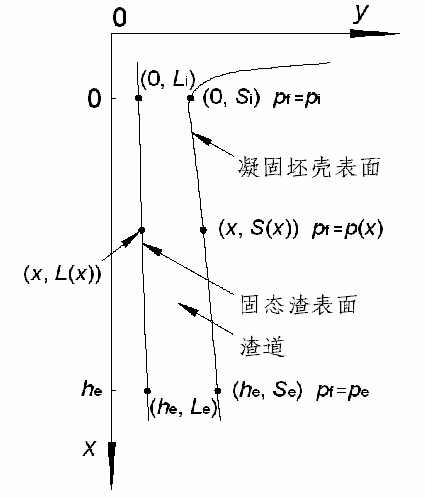

[0070] The method for determining the heat flux density of the copper plate of the continuous casting crystallizer based on the balance principle of the present invention is described in detail in conjunction with the embodiments and the accompanying drawings.

[0071] Step 1. Obtain raw data;

[0072] (1) Determination of viscosity and viscosity index: Table 1 shows the partial viscosity and viscosity index calculated according to equation (1).

[0073] Table 1 Viscosity and viscosity index settlement results

[0074] n , the temperature node variable

T , the temperature variable ( o c)

u , viscosity (Pa·s)

0.75

1389.82

0.1177

0.75

1390.51

0.1174

0.75

1391.30

0.1173

0.75

1392.81

0.1169

0.75

1393.53

0.1167

0.80

1389.82

0.1158

0.80

1390.51

0.1156

0.80

1391.30

0.1154

0.80

1392.81

0.1149

0.80

1393.53

0.1147

0.85

1389.82

0.11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com