Transmission roller of solar coated furnace

A technology of conveying rollers and solar energy, applied in the direction of roller column, sputtering coating, transportation and packaging, etc., can solve the problems of large temperature difference between the upper and lower glass and the influence of coating quality, and achieve the effect of small temperature difference and improved coating quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

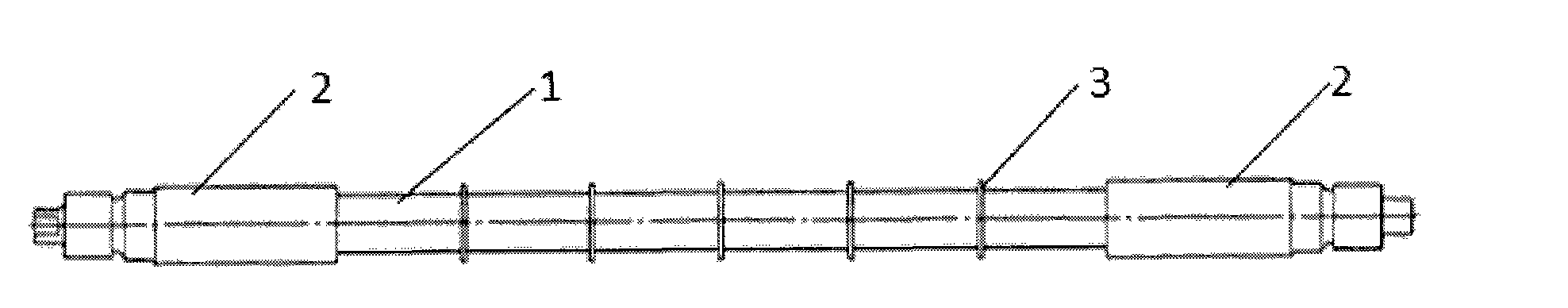

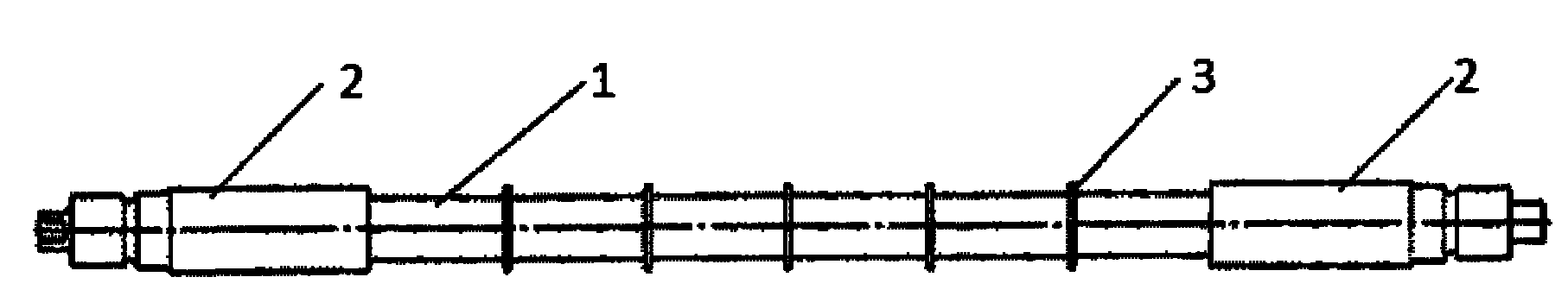

[0014] The invention discloses a solar coating furnace transmission roller, such as figure 1 As shown, a solid roller body 1 is included, and metal shaft heads 2 are arranged at both ends of the roller, wherein more than two protrusions 3 are arranged around the roller body 1 . The transmission roller formed by the roller body 1 and the protrusions 3 is integrally turned out by a lathe or a machining center, and the protrusions 3 are evenly distributed on the roller body 1 . The distance between the protrusion 3 and the outer surface of the roller body 1 is 2-10 mm. The roller body 1 is made of fused quartz, which will not pollute the glass during the conveying process.

[0015] Since the roller body is provided with protrusions, the glass will not directly contact the roller body, thereby ensuring a small temperature difference between the upper and lower surfaces of the glass, thereby improving the coating quality of the glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com