Milling, grinding and polishing device based on intelligent numerically-controlled platform

A technology of numerical control platform and polishing device, which is applied in the direction of grinding/polishing equipment, optical surface grinder, grinding machine, etc. It can solve the problems of insufficient flexibility, unadvanced algorithm, limited space, etc., and achieve wide versatility and high processing efficiency , easy to control and operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

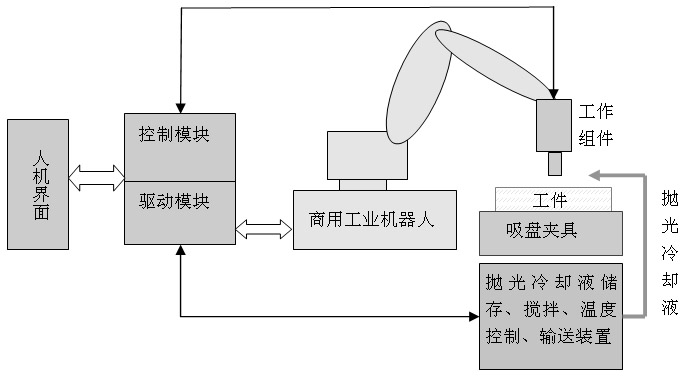

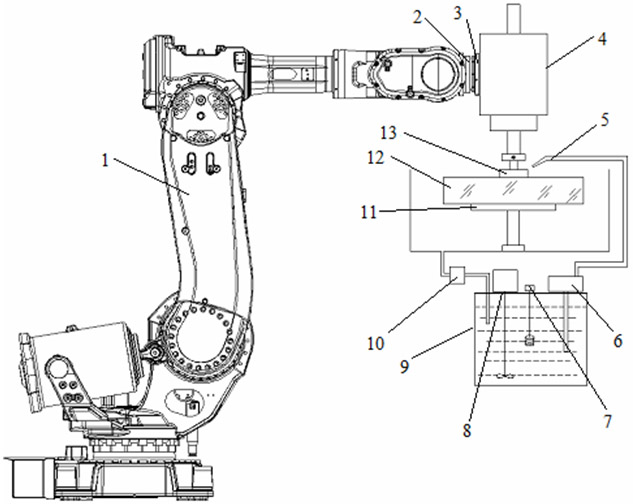

[0050] In order to describe the structure and features of the present invention in detail, the description is as follows in conjunction with the accompanying drawings. Such as figure 1 Shown is the composition block diagram of milling polishing device of the present invention, and it mainly is made up of 3 parts:

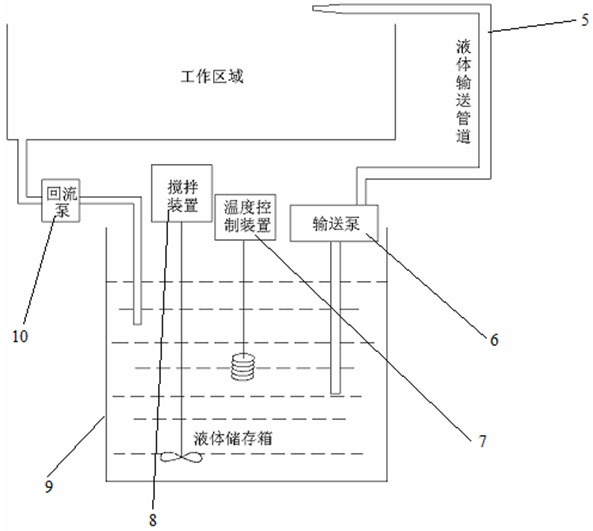

[0051] 1. Working component 4, namely the milling / polishing module component. This part adopts a modular design scheme, and the milling and polishing functions can be realized on the same machine only by changing the tool head. The working components are connected to the "wrist" of the robot through a flange. The working components perform self-rotation and horizontal swing motion through the planetary motion structure, and perform grinding or polishing actions, and the rotation speed and swing speed and amplitude can be adjusted. The tool head 13 is located below the working component 4, and the tool head 13 moves on the surface of the workpiece 12 with a remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com