Method for increasing true density of calcined coke for prebaked anode for aluminum electrolysis

A technology of prebaked anodes and aluminum electrolysis, which is applied in the field of increasing the calcined coke density of prebaked anodes for aluminum electrolysis, and can solve problems such as poor thermal shock resistance, increased carbon consumption, and increased cell voltage, achieving thermal shock resistance and The effect of improving the conductivity, shortening the calcination zone, and increasing the actual yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

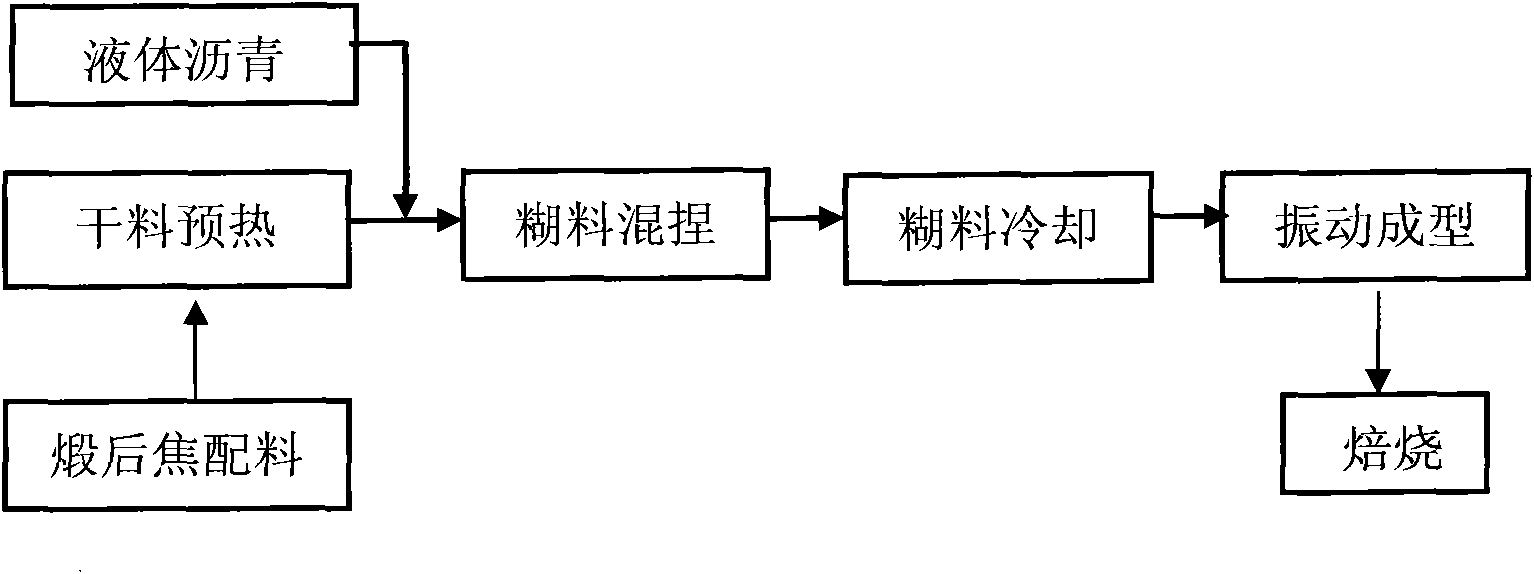

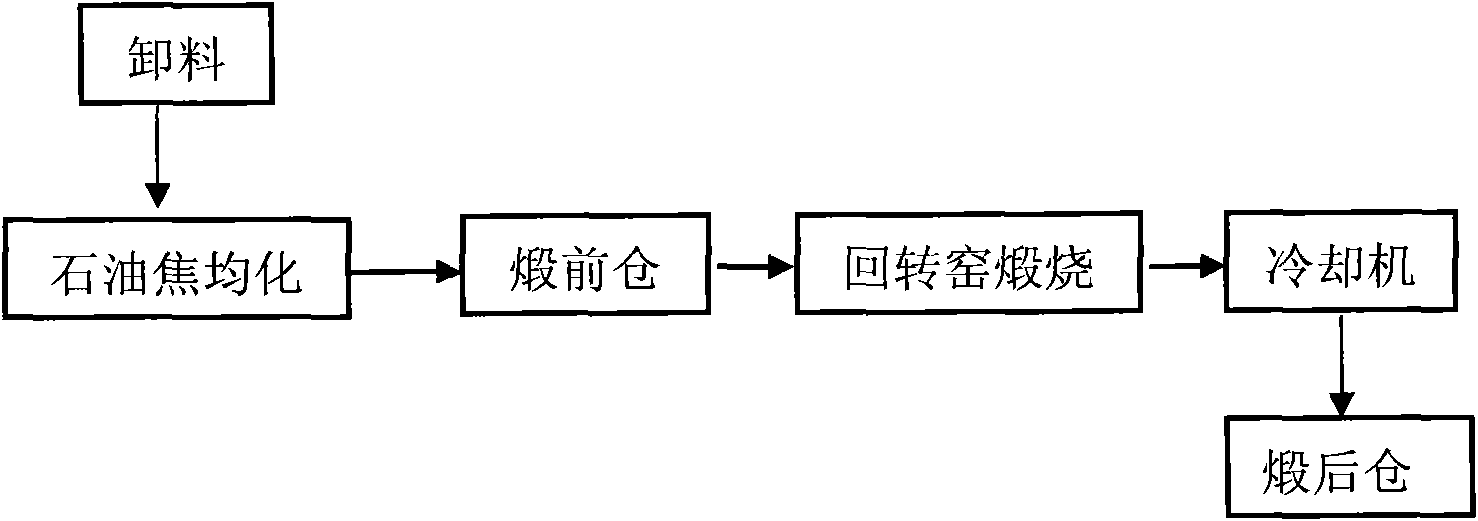

[0018] The Metso rotary kiln imported from the United States is adopted, with a specification of Φ4.0×68m, a kiln body length of 68 meters, and an inner diameter of 4.0 meters. After the installation and commissioning of the calcining system equipment is completed, the rotary kiln is heated to the required temperature according to the process requirements. The petroleum coke in the silo before calcining is quantitatively fed to the rotary kiln through the weighing system, and the raw petroleum coke entering the rotary kiln is gradually heated to 1500°C (can be at 1300-1500°C), the rotary kiln uses natural gas as fuel, and the calcination time is 70-100 minutes. The calcined coke enters the cooling machine, and the calcined coke is directly sprayed into the cooling machine for cooling, and aluminum electrolysis is obtained after cooling. The calcined coke used for the prebaked anode is sent to the calcined silo through the belt conveyor and bucket elevator for storage. The proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com