Arc plasma gun

A technology of arc plasma and spray gun, applied in the direction of plasma, electrical components, etc., can solve the problems of high emission of greenhouse gases, large consumption of coal resources, and low quality of synthesis gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

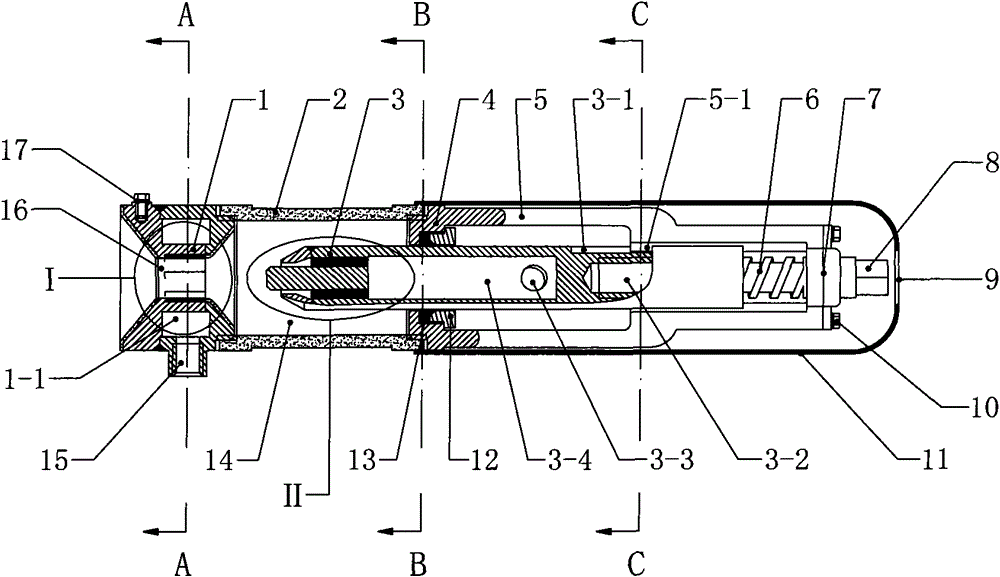

Embodiment 1

[0036] Example 1 figure 1 In the shown embodiment, arc plasma torch is mainly made up of anode (1), cathode (3), gun barrel (2), backseat (4), air chamber (14) and protective cover (11), wherein: The anode (1) is a hollow annular body structure, the ring center space of the annular body constitutes the spout (16), the annular cooling groove (1-1) is arranged in the annular body, and the annular cooling groove (1-1) has a cooling water interface (15) connected to the There are cooling water vaporization holes (1-2) and steam injection grooves (1-3) on the ring wall between the annular cooling groove (1-1) of the anode (1) and the spout (16), wherein the cooling The water vaporization hole (1-2) is a circular hole structure, and 6 groups of cooling water vaporization holes are arranged in a ring shape, and each group has five cooling water gasification holes; the inlet of the cooling water gasification hole (1-2) is in the ring Cooling tank (1-1), the outlet is connected to the...

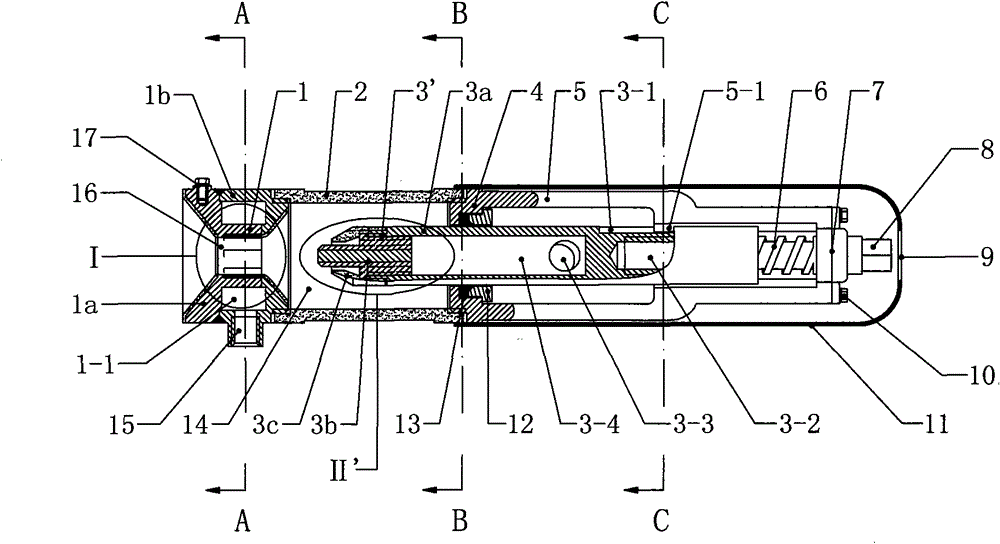

Embodiment 2

[0037] Example 2 figure 2 In the shown embodiment, replace the cathode (3) in the first embodiment with combined cathode (3 '), the combined cathode (3 ') consists of cathode rod (3a), cathode head (3b) and cathode cap (3c), wherein, the cathode rod (3a) has a tubular structure from the middle section to the front end, and the space in the tube forms a cooling chamber (3-4), and the cooling chamber (3-4) has a working water interface (3-3) connected to it ; The front end of the cathode head (3b) is a tapered conical surface, and the back of the conical surface is a cylindrical entity, and there are vaporization ribs (3b-1) on the rear entity of the cathode head (3b), and the vaporization ribs (3b-1) It is arranged in a multi-piece ring, and the gap between the vaporization ribs (3b-1) forms a vaporization chamber (3-9), and the vaporization fins (3b-1) have an assembly flange (3b-2); the cathode cap ( 3c) Fasten the assembly flange (3b-2) on the cylinder wall at the front en...

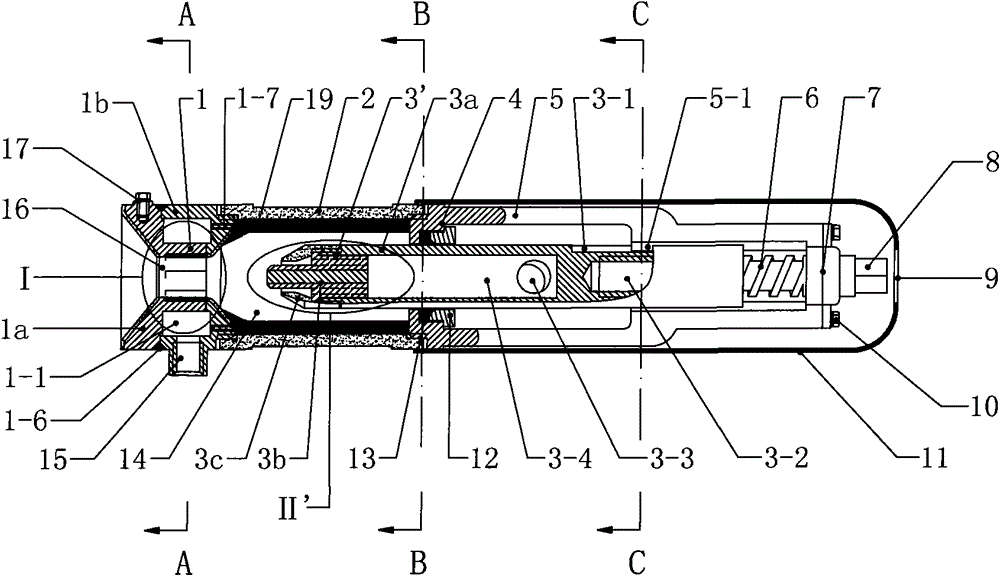

Embodiment 3

[0038] Example 3 Figure 14In the shown embodiment, arc plasma torch is mainly made up of anode (1), cathode head (3b), cathode cap (3c), gun barrel (2) and cathode base (18), and the gun barrel (2) The rear end is connected to the cathode base (18) to form the gun body, the anode (1), gun barrel (2) and cathode base (18) are coaxially arranged, and the anode (1) is connected to the front end of the gun barrel (2) , the annular center space of the anode (1) constitutes the spout (16), the inner space of the gun barrel (2) forms the air chamber (14), the cathode base (18) constitutes the rear closed end of the gun barrel (2), and the cathode head ( 3b) Set in the gun body, the cathode cap (3c) fastens the cathode head (3b) on the cathode base (18), and the space between the cathode head (3b) and the anode (1) constitutes a discharge space; wherein, the anode (1) It is a hollow annular body structure, and there is a power terminal (17) on the outside of the annular body, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com