Method for preparing filter membrane mesh structure by laser interference photoetching technology

A technology of laser interference lithography and filter film, which is applied in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of high cost, poor controllability of mesh structure parameters, complicated manufacturing process, etc. Simple, process saving, controllable structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

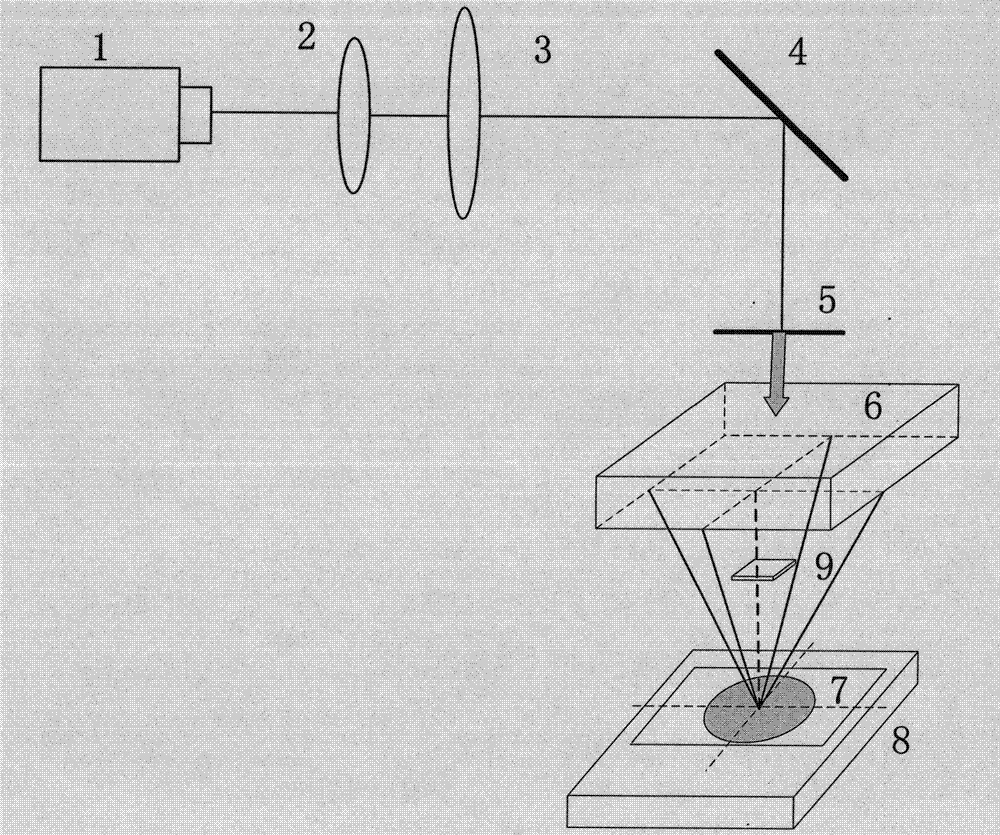

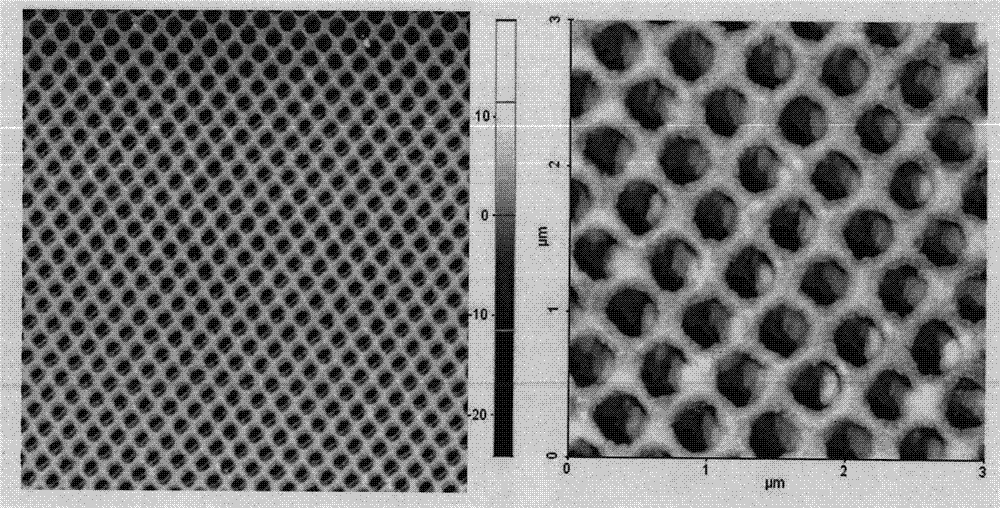

[0024] Such as figure 1 shown by figure 1 The system shown uses a combination of four laser beams to create a filter membrane mesh structure on the surface of a substrate material. The four beams of coherent light emitted by the beam splitting and refracting system 6 interfere with each other and expose the substrate 7 to form a filter membrane mesh structure. figure 2 For this system, the four-beam laser interference nanolithography method is used to make the atomic force microscope image of the filter membrane mesh. For the method of forming a specific large-area mesh structure, after expanding the beam on the basis of satisfying the allowable range of the light energy threshold, combined with the moving substrate workpiece table 8 or the interference optical system 6, the substrate 7 is scanned and exposed with a multi-beam interference pattern, Form a large-area filter membrane mesh structure.

[0025] The method of forming a specific high-density filter membrane mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com