Tilting air cylinder

An air cylinder and intermediate cylinder technology, applied in the field of railway freight cars, can solve the problems of difficult machining of tipping air cylinders, unsmooth working process, many casting defects in castings, etc., so as to eliminate swing phenomenon, avoid casting defects, reduce scrap rate and The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

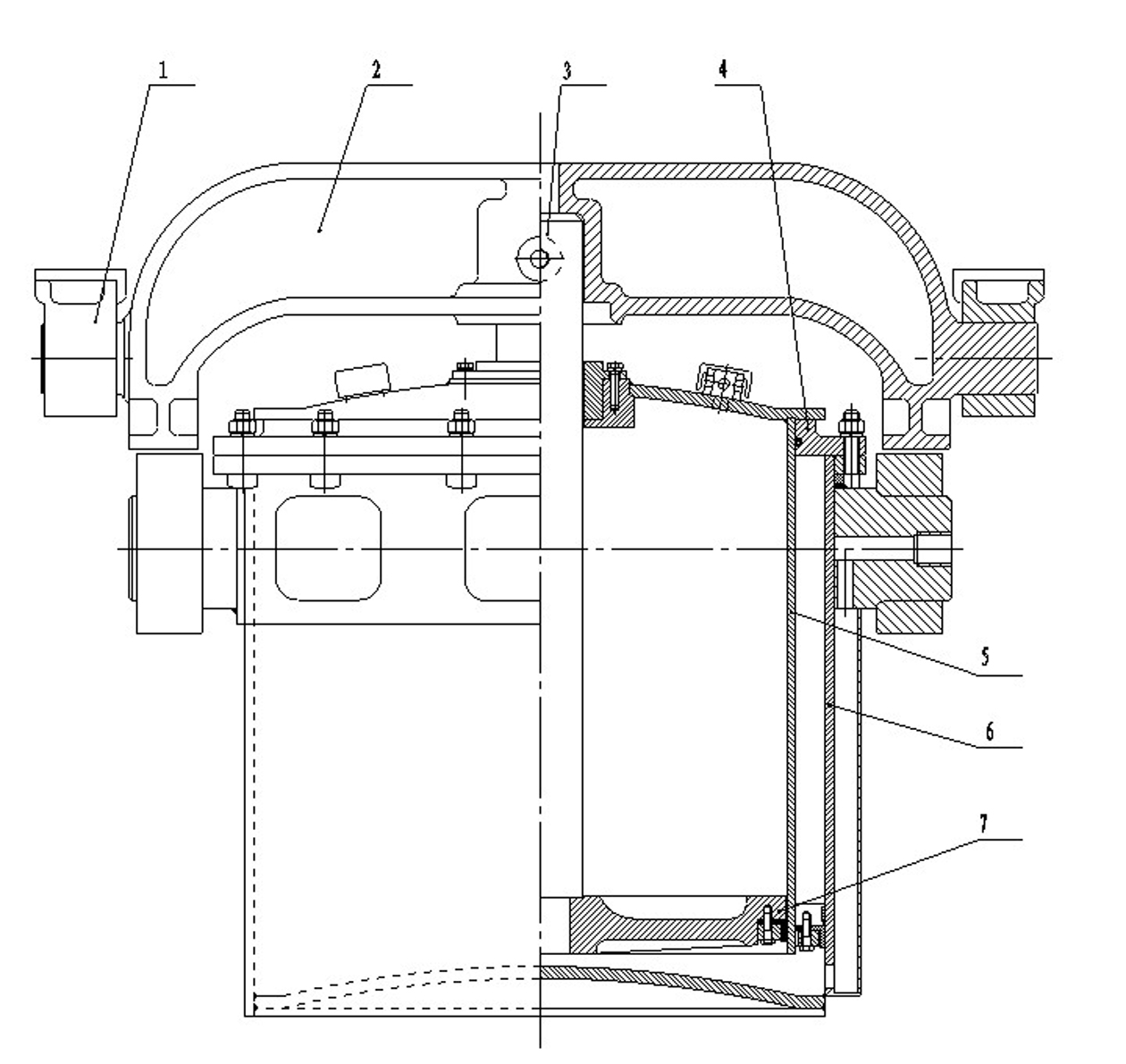

[0024] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0025] 1. Change the structure and forming method of the outer cylinder 6 and the middle cylinder 5, and change the casting into a weldment.

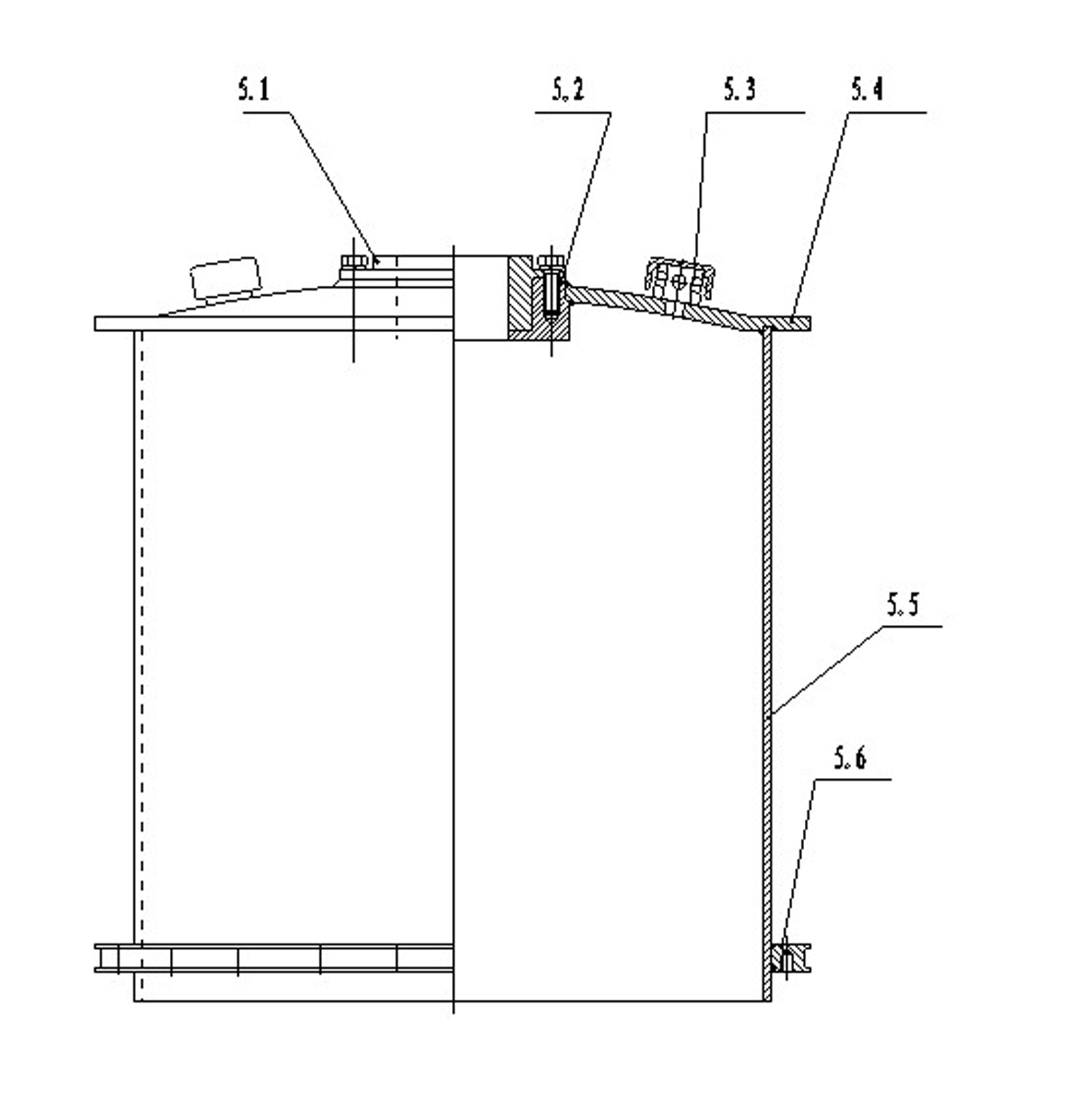

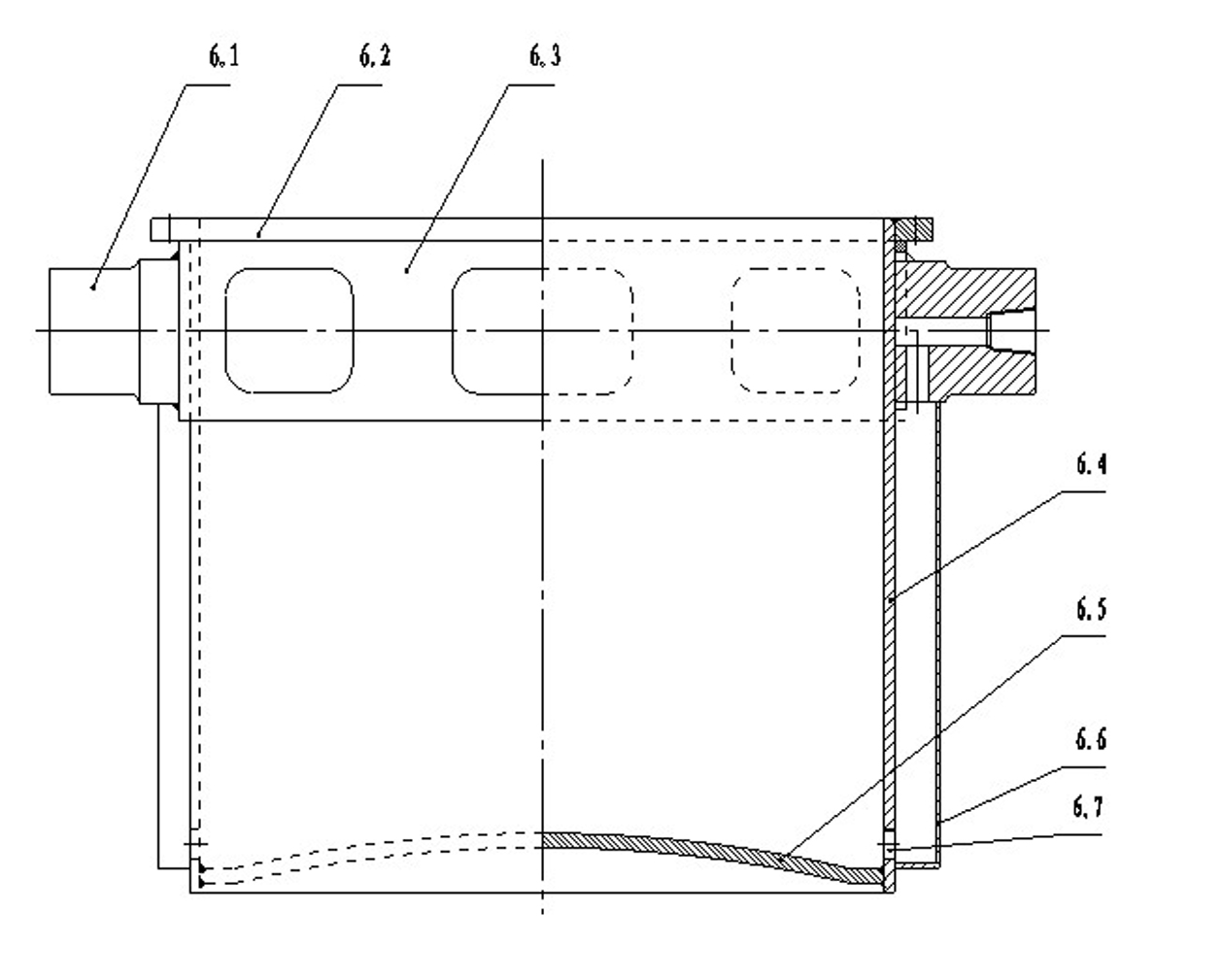

[0026] The outer cylinder 6 is changed from the original one-piece casting to be processed after assembly welding of parts such as ear seat 6.1, upper flange 6.2, reinforcement sleeve 6.3, outer cylinder body 6.4, air pipe 6.5 and base 6.6. In addition, the outer cylinder body 6.4 is welded by plate rings into a cylindrical shape; the middle cylinder 5 is also changed from the original one-piece casting to the outer piston cup fixing ring 5.6, the inner cylinder barrel 5.5, the inner cylinder barrel cover 5.4, and the air release device 5.3, support plate 5.2, guide sleeve 5.1 and other components are processed after assembly and welding. And the inner cylinder barrel 5.5 is welded into a cylindrical shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com