Low-migration o-benzoyl benzoate

A technology of free radicals and compounds, applied in the field of low-mobility phthaloyl benzoate, can solve the problems of small molecular weight of photoinitiators, sources of new compounds, synthesis methods, structural characterization, property disclosure, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

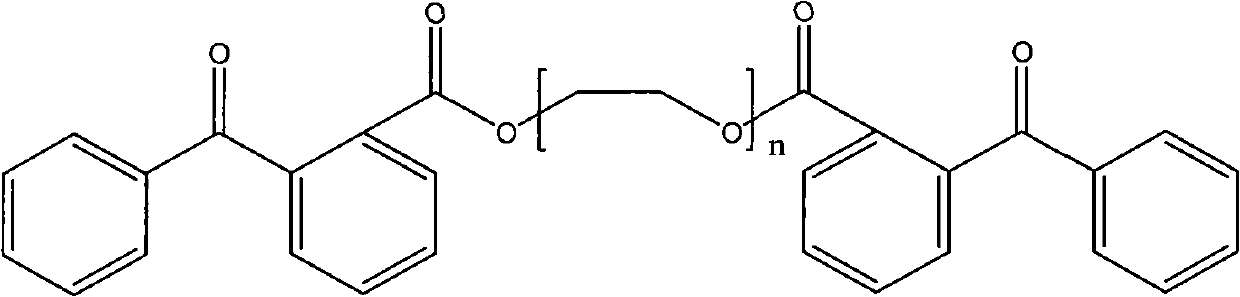

[0021] Triethylene glycol bis(phthaloylbenzoate) ester

[0022] In a 500 ml four-necked flask, add 97.1 grams (0.5 moles) of tetraethylene glycol, 82.5 grams (1.0 moles) of methyl phthaloylbenzoate and 8 g of sodium methylate, and heat up to 130° C. and stir the reaction for 8 hours. Methanol is recovered at the same time. After cooling down, it was washed with water, and the water was evaporated under reduced pressure to obtain a yellow viscous substance. With ethyl acetate petroleum ether mixed solvent as eluent, the above-mentioned product is carried out column chromatography purification, obtains light yellow oily matter main distillate, through HPLC analysis, triethylene glycol bis-phthaloyl benzoate ( In structural formula 2, the compound with n=4) content was 98%, and the yield was 53%. Elemental analysis data: the measured value of C is 70.40 (theoretical value 70.81); the measured value of H is 5.82 (theoretical value 5.61). See Table 1 for H NMR spectrum data and ...

Embodiment 2

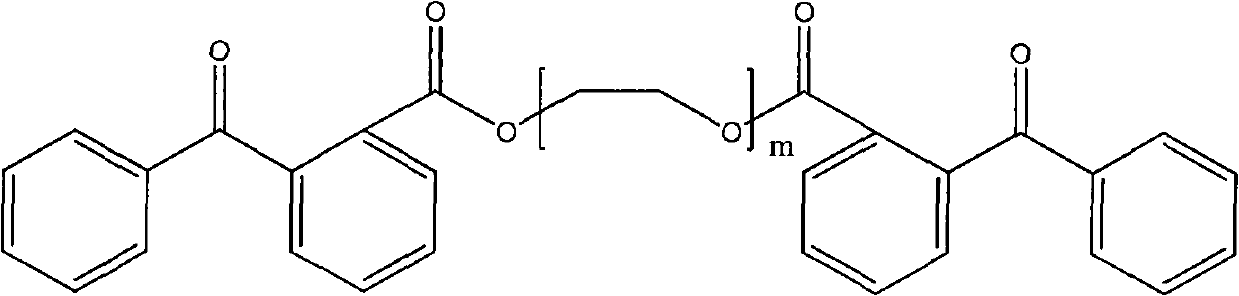

[0027] Example 2 Polyethylene glycol 200 di-phthaloylbenzoate

[0028] In a 500 ml four-necked bottle, add 100 grams (0.5 moles) of polyethylene glycol 200, 82.5 grams (1.0 moles) of methyl phthaloylbenzoate and 8 g of sodium methoxide, heat up to 130 ° C and stir the reaction for 8 hours, while Methanol is recovered. After cooling down, wash with water, and evaporate water under reduced pressure to obtain 180 grams of light yellow product polyethylene glycol 200 bis-phthaloylbenzoate (in structural formula 2, a mixture of n=4-10 compounds), with a content of 98.15%. The yield was 97.4%. The HPLC-MS analysis results are shown in Table 2.

[0029] Table 2 Liquid chromatography-mass spectrometry analysis results

[0030]

Embodiment 3

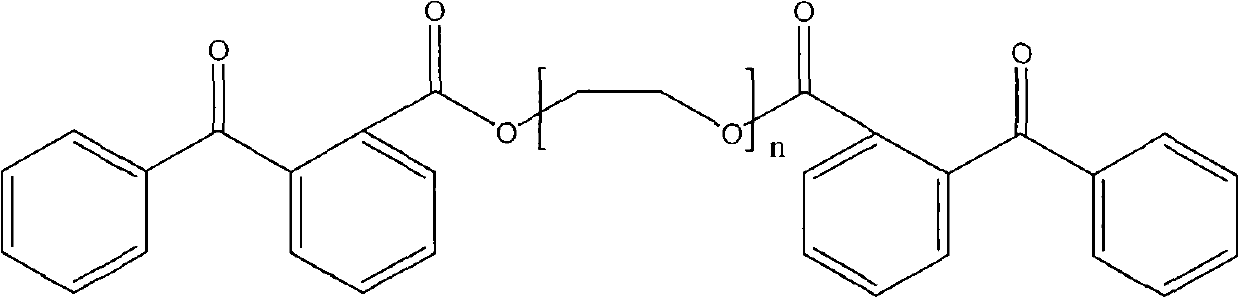

[0032] Embodiment 1, 2 product curing performance comparisons

[0033] The product prepared by Examples 1 and 2, methyl phthaloylbenzoate and benzophenone are respectively used as photoinitiators to make corresponding ultraviolet curable varnish compositions. The formulation of the composition is shown in Table 3.

[0034] table 3

[0035]

[0036] The prepared varnish composition was applied to paper with a 25 micron wire bar coater and cured at a speed of 100 m / min with a medium pressure mercury arc lamp with a power of 100 watts / cm. Record the number of lamp passes required to obtain a good surface and a thorough cure. The maximum odor is 5 grades, and the minimum is 1 grade. The results are shown in Table 4.

[0037] Evaluation results of different photoinitiators in table 4

[0038] Photoinitiator

[0039] The experimental results show that the products of Examples 1 and 2 have very little odor, are fully cured, and have a bright and non-sticky film surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com