Surface treatment method for filter cavity, cavity filter and communication apparatus

A cavity filter and surface treatment technology, which is applied in the field of communication, can solve the problems of high cost and the inability of connecting components to meet the requirements of corrosion resistance and wear resistance, and achieve the effect of meeting the requirements of corrosion resistance and wear resistance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A surface treatment method for a filter cavity, the cavity filter includes a cavity and a connecting member integrally formed with the cavity, wherein the surface treatment method for the filter cavity includes the following steps:

[0028] A first electroplating step, in which the connecting member is shielded, and the cavity is plated with a first material so that the cavity meets the electrical performance requirements of the cavity filter; and

[0029] A second electroplating step. In the second electroplating step, the cavity is shielded, and the connecting member is electroplated with a second material, so that the connecting member meets the requirements for anti-corrosion and wear resistance.

[0030] The surface treatment method of the filter cavity provided in this embodiment performs different surface treatments for different parts of the cavity filter, and at the same time meets the electrical performance requirements of the cavity and the anti-corrosion and ...

Embodiment 2

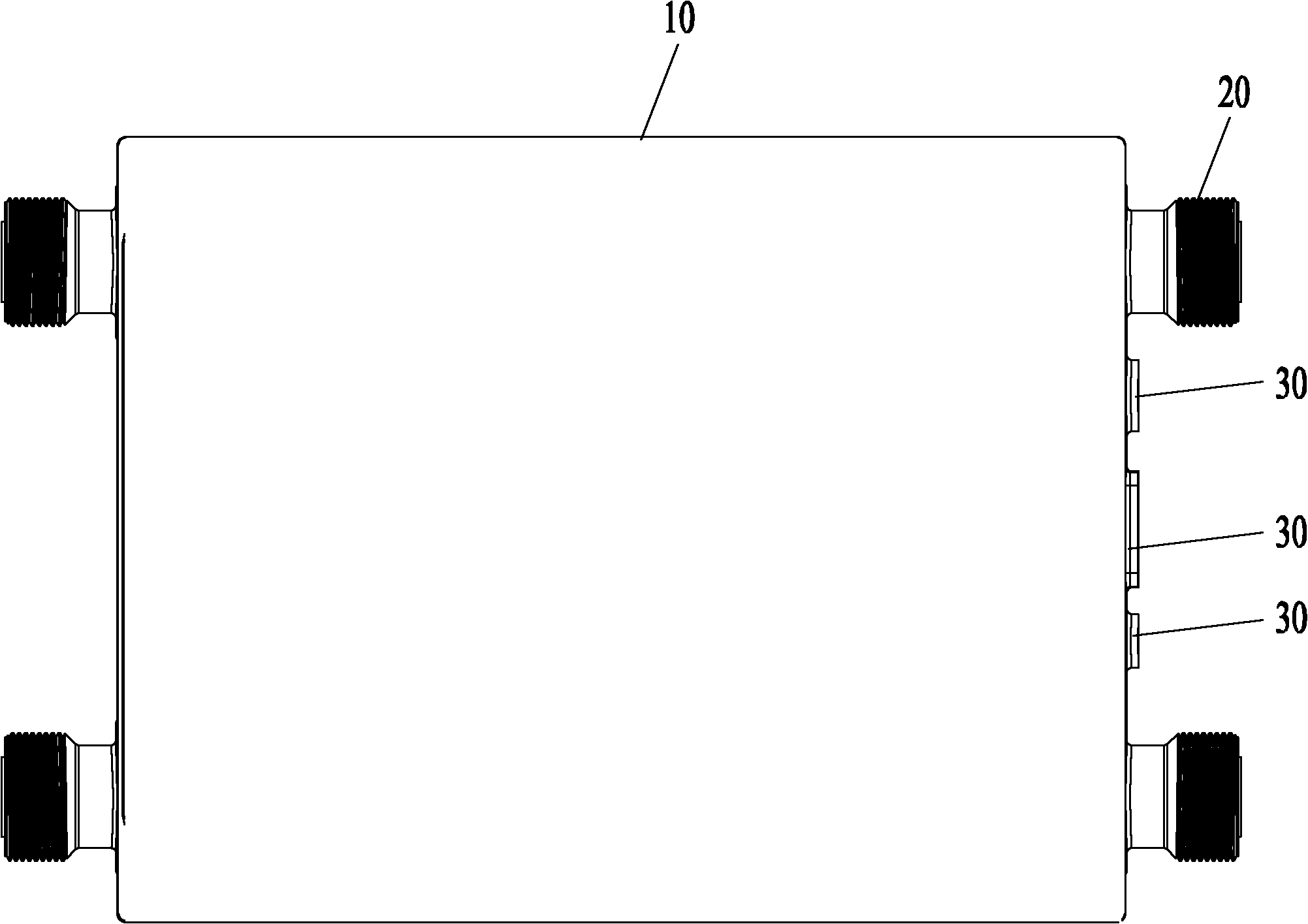

[0032] A surface treatment method for a filter cavity. Please also see Figure 1 to Figure 5 ,in, figure 1 A simplified flowchart of a method for surface treatment of a filter cavity according to a preferred embodiment of the present invention is shown. The cavity filter provided in the embodiment of the present invention mainly includes a cavity 10 and a connecting member 20 integrally formed with the cavity 10. In this embodiment, the surface treatment method of the filter cavity includes the following steps in sequence:

[0033] Step 1: the first pretreatment step, in this step, including the sub-steps of acid degreasing, pickling, neutralization and galvanizing on the cavity 10 .

[0034] Step 2: the first electroplating step. In the first electroplating step, the connection member 20 is first shielded, and then the cavity 10 is electroplated with a first material, so that the cavity 10 meets the electrical performance requirements of the cavity filter. In this embodime...

Embodiment 3

[0042] A cavity filter. Please also see Figure 2 to Figure 5 , which respectively show different views of the cavity filter according to the preferred embodiment of the present invention, the cavity filter provided according to the preferred embodiment of the present invention includes a cavity 10 and a connecting member 20 integrally formed with the cavity 10, The connecting member 20 is arranged on the side of the cavity 10, the connecting member 20 is provided with an inner hole communicating with the cavity 10, and the side wall of the cavity 10 is further provided with a plurality of special connecting holes 30, of course, the connecting member The positions of 20 and the plurality of dedicated connecting holes 30 are not limited to those shown in the drawings. Of course, the cavity filter provided by the embodiment of the present invention also includes various other conventional components or structures. Here, this embodiment only describes the parts related to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com