Liquid level adjusting device, compressor shell and compressor

A technology of liquid level adjustment device and compressor shell, which is applied in the field of compressors, can solve the problem of insulation resistance reduction, etc., and achieve the effect of lowering the oil level, simple structure and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

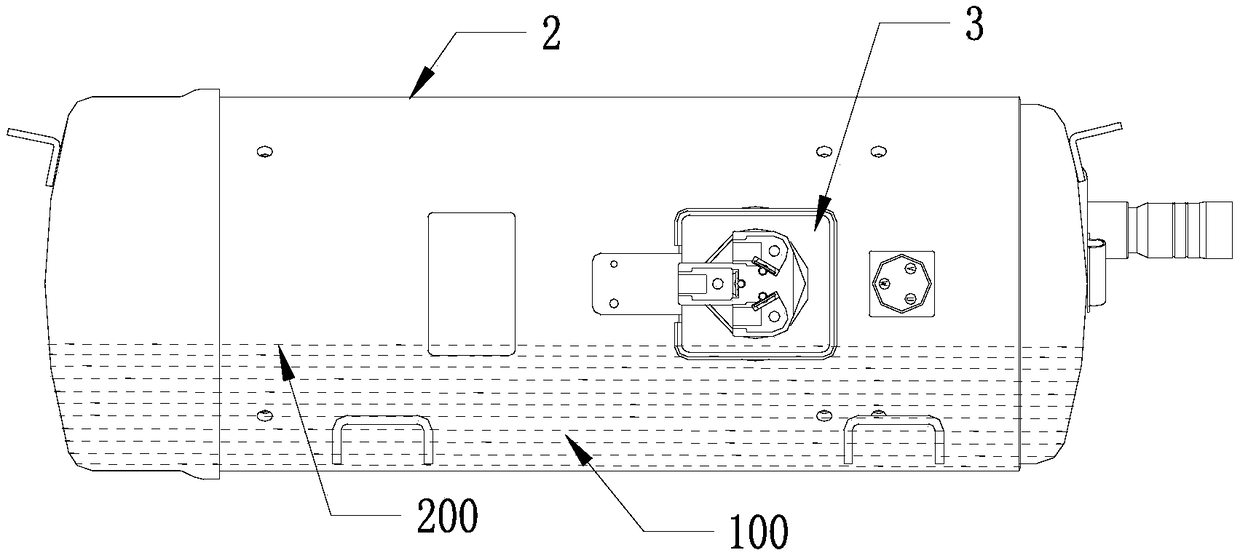

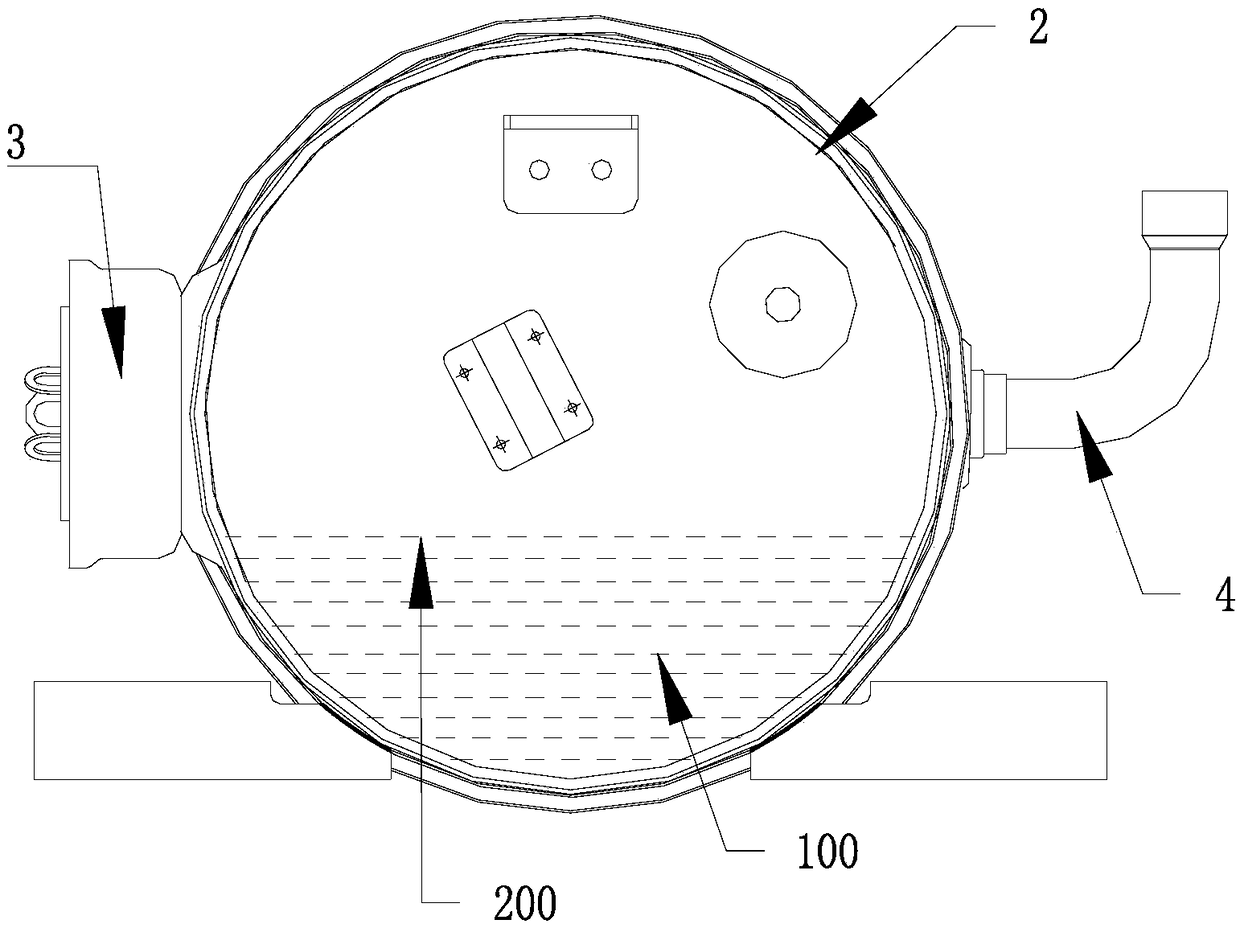

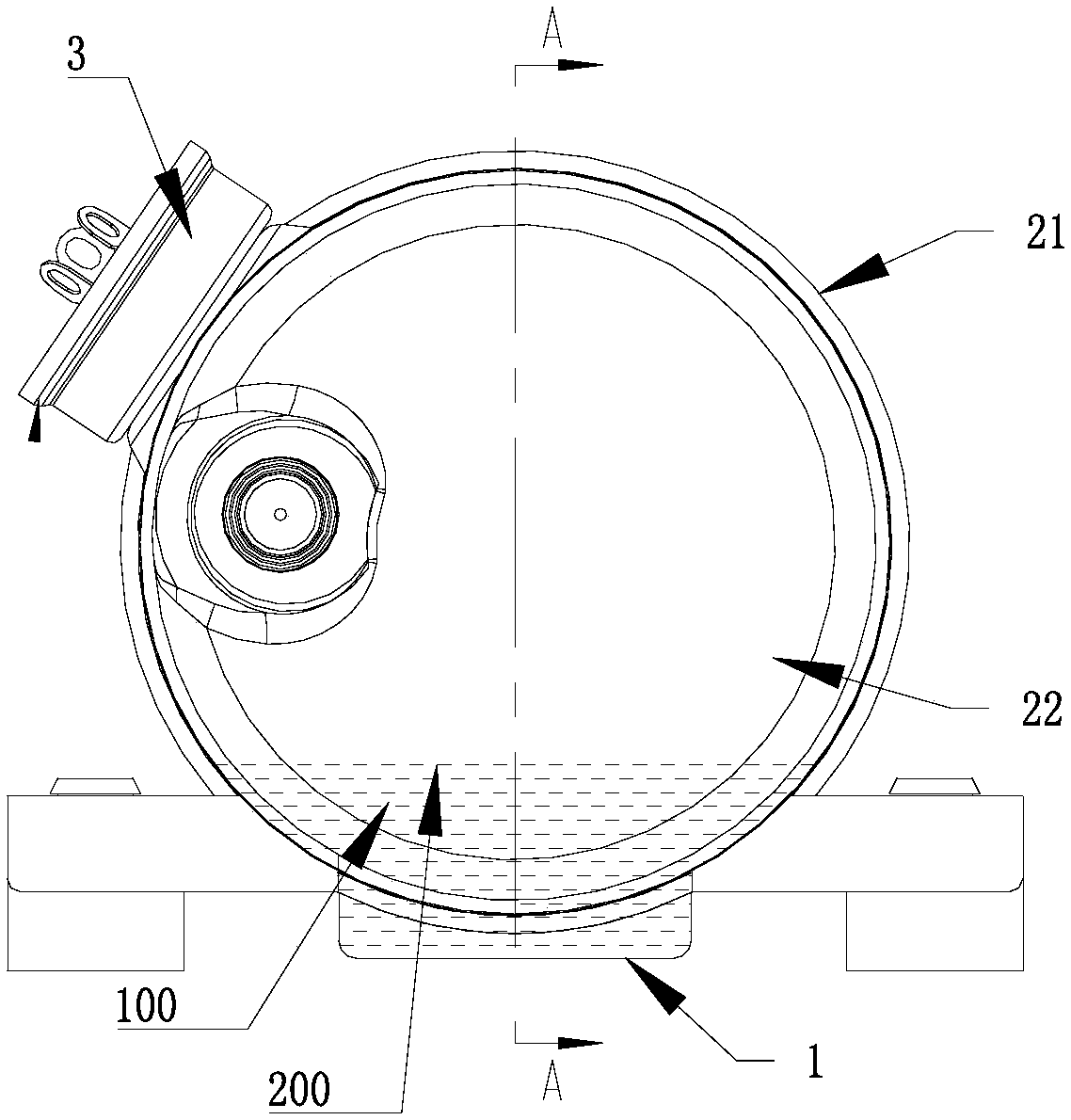

[0039] Such as image 3 As shown, the present invention provides a kind of liquid level regulating device, comprises regulating device body 1, and regulating device body 1 is arranged on the bottom of compressor casing 2, has volume chamber in regulating device body 1, volume chamber and compressor casing The inner cavities of the body 2 are communicated, and at least part of the liquid medium in the compressor housing 2 is introduced into the volume cavity so that the connection between the wiring device 3 on the compressor housing 2 and the liquid medium 100 in the compressor housing 2 The distance between the liquid levels 200 increases. The present invention fills part of the mixed liquid of lubricating oil and refrigerant into the regulator body 1 at the bottom of the compressor housing 2, thereby lowering the oil level 200, which can effectively solve the problem that the terminals on the compressor housing 2 are close to the oil level 200. The problem is to increase th...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is that the liquid level adjustment device is arranged at the bottom of the shell body 21 and the bottom of the end cover 22, and the adjustment device body 1 and the shell body 21, and the adjustment device body 1 and the end cover 22 are integrally formed. , this embodiment 2 also has two optional design schemes, the first one, such as Figure 7-Figure 9 As shown, the adjusting device body 1 is arranged on the bottom of the shell body 21 and the bottom of the two end covers 22, that is, the bottom of the shell body 21 and the two end covers 22 protrude downwards, and are spliced together to form the adjusting device body 1 and the end covers The downward protruding parts on 22 form the side walls at both ends of the tank structure, and the downward protruding parts of the bottom of the shell body 22 form both side walls and the bottom plate of the tank structure, through the protruding parts of the shell body 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com